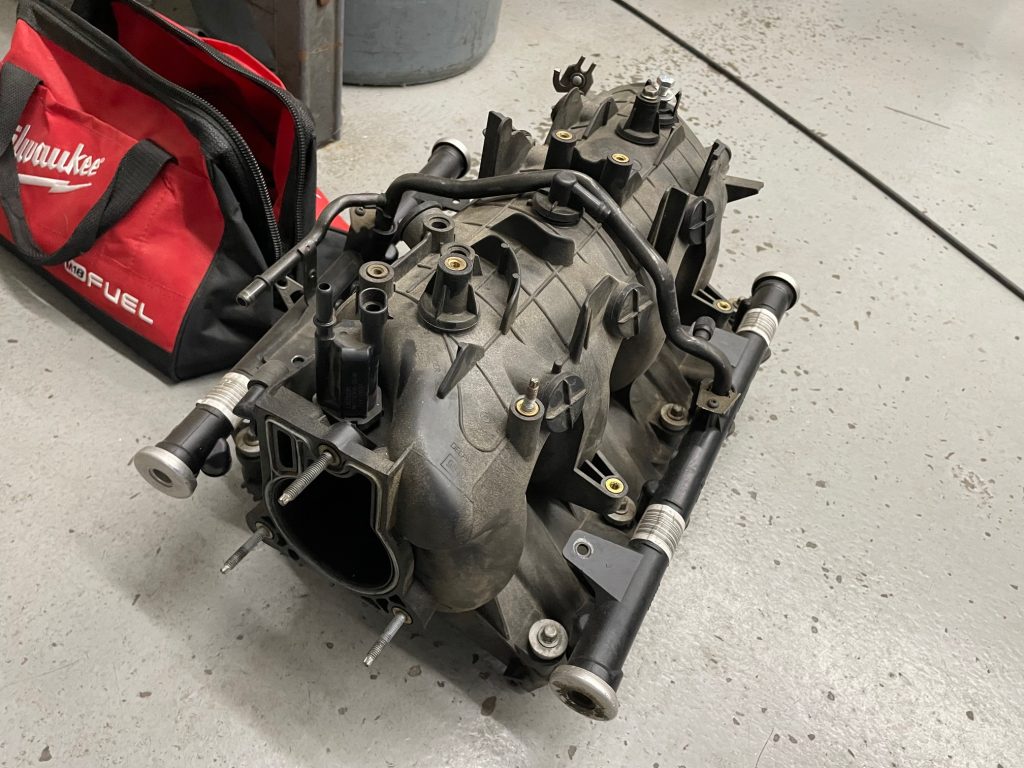

By now it should come as no surprise to anyone that the very best factory intake manifold for a cathedral-port LS application is the Trailblazer SS, often referred to simply as the TBSS.

The revised intake design, compared to the original unit used on all the early truck motors (shared by 4.8L, 5.3L and 6.0L engines) offered improved power. Testing has shown the TBSS to be better than the factory LS1, LS2, LS4, early truck and even the mighty LS6—though the LS6 is very close in performance. The limiting factory on the LS6 intake would eventually be the smaller throttle opening, as the LS6 was designed for the smaller (75 to 78mm) LS1-style throttle body, where the TBSS was designed for the later (86 to 90mm) drive-by-wire throttle body.

At higher power levels, the larger throttle opening offered by the TBSS intake would come into play, though it must be stated that the power gains offered by the TBSS intake over the other factory designs is not simply a matter of throttle body sizing. The intake design elements (runner length, diameter, taper, plenum volume, etc.) all come into play when determining the effectiveness (and power production) of the intake manifold.

We know the TBSS intake is a desirable intake manifold, and it is much more readably available and affordable than the LS6. As a side note, the Dorman LS6 and LS2 style manifolds make a nice alternative, especially for vehicles with hood clearance issues—I’m taking to you Camaro, Corvette, and GTO owners. The problem with the Dorman versions is cost and availability. Time was when the Dorman intakes were dirt cheap and readily available, but after some positive testing by you-know-who, the price on them skyrocketed, placing them near (in cost) to the FAST LSXR intake manifolds (which are superior in power to all of these), but will also set you back a cool $1,200 or more.

If you have the hood clearance, the TBSS intake is tough to beat for performance and price, at least among the factory intakes.

The Role of Throttle Body Size

The question here is not whether the TBSS intake adds power over the stock truck intake (it does), but do you have to also upgrade to a larger throttle body when upgrading your truck intake? The extra expense of the larger throttle body (unless your TBSS came equipped with one) makes the intake swap less affordable, but how much would you be restricting the gains offered by the TBSS if you installed smaller throttle body with an adapter rather than upgrade to a 90mm throttle body?

One of the things that determines the answer to our intake/throttle body question is the test motor. We know from testing that if we add a TBSS to a stock 4.8L or 5.3L, the gains would be less than if we perform the same swap on a 6.0L. The same goes for modified versions of each, as the higher the power output of the test motor, the more power you get from swapping the intake. On a 300 hp motor, the gains are less than on a 400 or 500 hp motor. The same goes for our throttle body question, as the stock 75-78mm throttle body can easily support the flow needs of a stock 4.8L, but the smaller throttle body becomes more of a restriction on a modified 6.0L (or bigger).

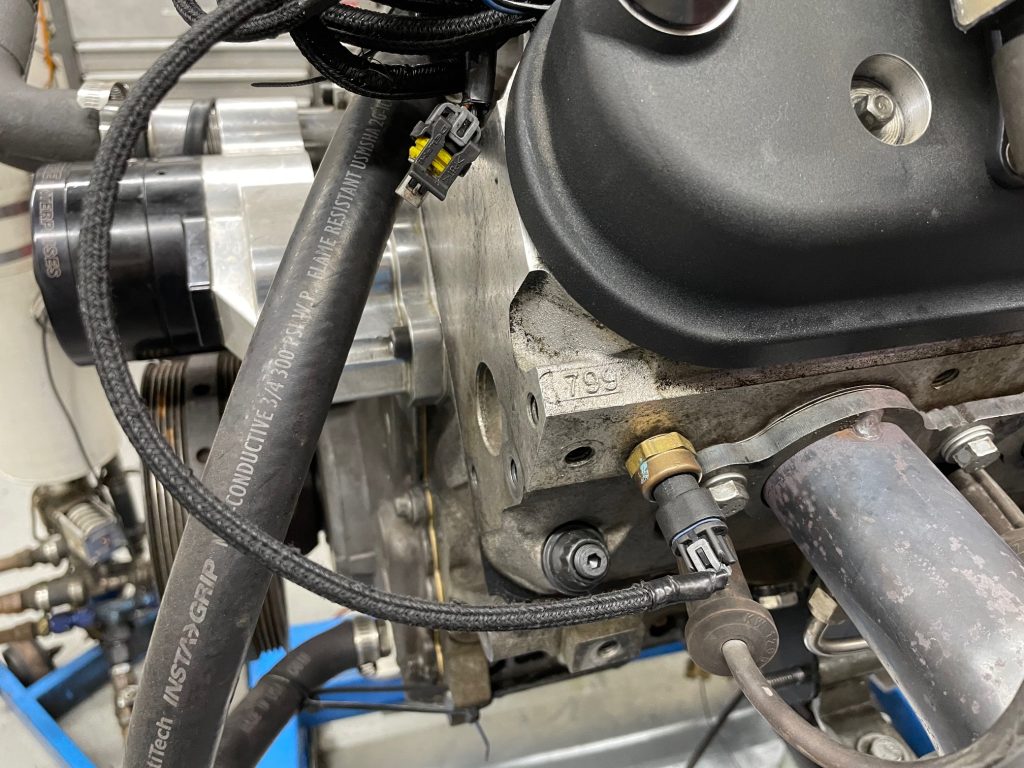

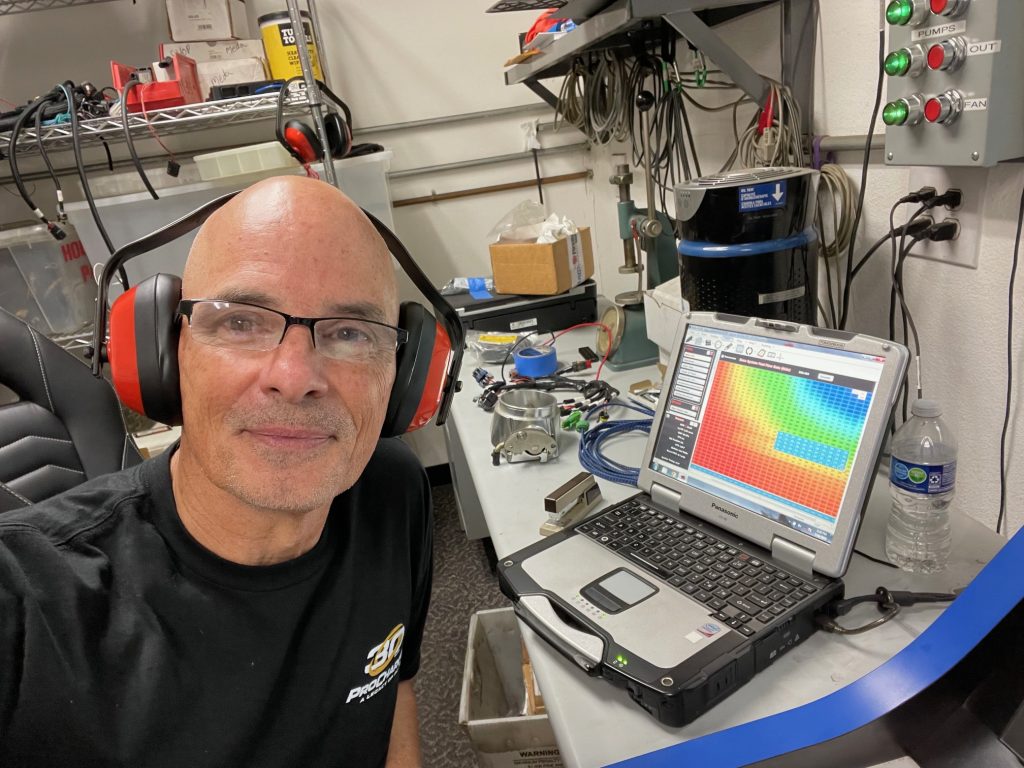

For our test, we selected a mild 5.3L equipped with a cam. The choice was more one of convenience, rather than design, as the junkyard, aluminum 5.3L L33 has become a mainstay for testing to the tune of over 700 dyno pulls! It has been used to test all manner of intakes, cams, heads, nitrous and boost, but for this test, the L33 was returned back to near stock trim. This configuration included the stock short block, stock 799 heads (with a BTR valve spring upgrade) and stock early truck intake and manual throttle body. The non-stock modifications included a .552/.552 lift cam upgrade, 1-7/8 long-tube headers and 1,000cc injectors. Tuning was via a Holley HP management system.

To test itself involved first running the 5.3L with the TBSS intake (the L33 came factory equipped with the early truck intake) and manual 75-78mm early truck throttle body using an ICT billet throttle body adapter. The adapter was necessary to convert the larger 90mm, 4-hole throttle body flange on the TBSS intake to the 3-hole, 75-78mm throttle body used on the early truck intake.

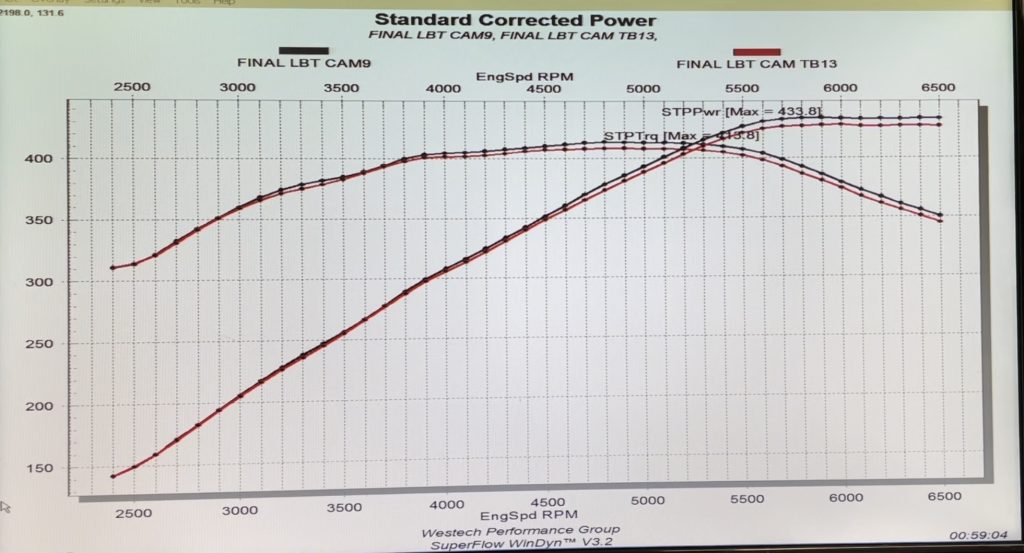

Run with the smaller throttle body on the TBSS intake, the 5.3L produced 427 hp and 411 lb.-ft. of torque. After installation of the larger 92mm FAST Big Mouth throttle body (which better matched the opening on the TBSS intake), the power output increased to 434 hp and 416 lb.-ft. of torque.

Since airflow requirements increase with engine speed, it is not surprising that gains offered by the larger throttle body came past 4,500 rpm. Using the Holley HP system, we also logged the kpa during the run and the larger throttle body showed a peak of 96 kpa to the slightly more restrictive 95 kpa offered by the smaller throttle body.

FYI: Tuners, he scaling on the MAP sensor meant 96 kpa was zero vacuum (not 100 kpa).

The upshot of this test shows that the early truck throttle body can be run on the TBSS, but it will cost you some power at the top of the rev range. Remember too, the greater the power output of your test motor, the more you will benefit from the larger throttle body.

.

Comments