Square body GM trucks and LS engines is a combo that’s close to hot rod heaven. Some may say it’s been overdone at this point. However, being a part of a younger generation (I’m 27) means the LS engine is to me what the small block Chevy is to my dad (he’s 68). Despite the recent boom in popularity, GM square body trucks are relatively affordable while offering a great platform to build on. So, that’s what I did.

This all started with buying a 1975 GMC dually to the tune of a couple grand. The plan was simple: slap a rather large turbo on a 6.0 LS, dump it in this unsuspecting truck, and drive around to see if someone would recognize the whistling sound coming from the exhaust. A sleeper, one might say.

Story Overview

- Former PowerNation TV host Jimmy King builds a turbo LS engine using a 6.0L LQ4 short block and a Summit Racing turbocharger

- The short block was upgraded with ICON forged pistons and SCAT forged connecting rods

- The Summit Racing Performance Turbocharger is rated for up to 800 to 900 rear-wheel horsepower

- Learn how Jimmy plumbed the hot and cold sides of the turbocharger system

The Engine

Knowing that I wanted the engine to make power somewhere in the 500 rear-wheel horsepower range and do it safely, I decided to start with a junkyard LQ4 short block. This would provide enough displacement that only a small amount of boost would be required to reach the power goal.

The Short Block

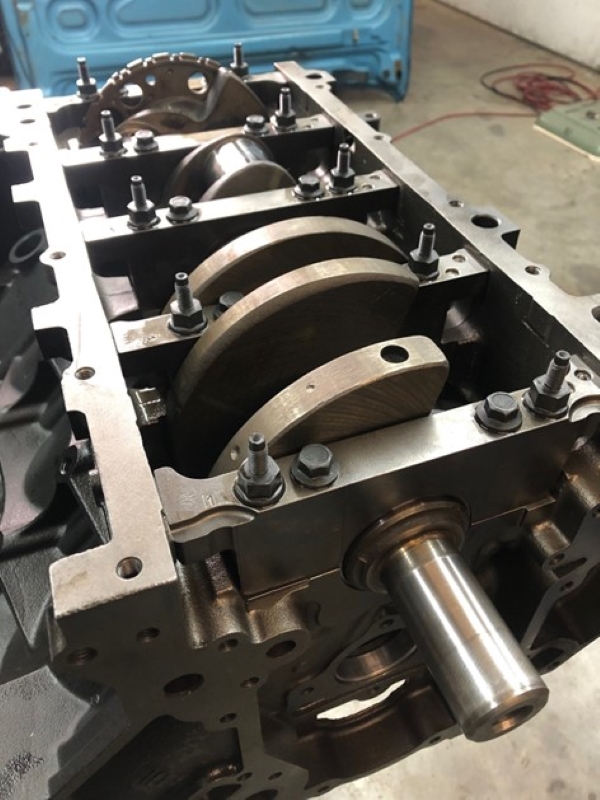

After tearing the engine down, I kept the crankshaft but gave the rest of the rotating assembly a ride to the scrapyard. The crankshaft just needed the journals polished to be assembly-ready. The block got the full machine shop treatment including align honing, cylinder honing, and deck surfacing.

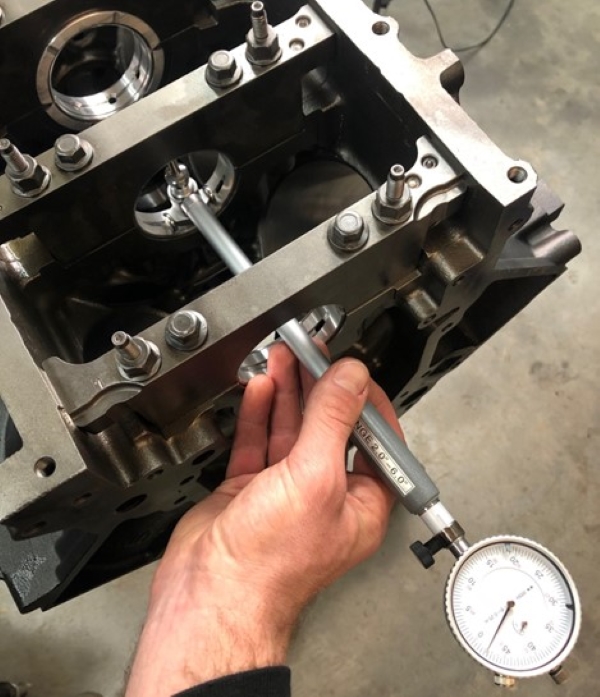

All connecting rod and crankshaft journal bearing clearances met my target range of .002-.003-inch. I did have to swap around bearing shell halves on a couple of the crank journals to get there, but the connecting rods were spot-on.

I ended up going with a forged piston/rod combo—ICON FHR pistons and 6.125-inch Scat H-beam rods. While I planned to run about eight PSI of boost, I opened the top and bottom piston ring gap to .028-inch just in case I really wanted to wake this engine up with more boost. If I remember correctly, ring gap out of the box was .020-inch.

I have a few of the tools needed to do a basic engine build, but I had to get creative in other areas. For example, I have a dial bore gauge but I don’t have a connecting rod vise to hold the rods while torquing the caps. Putting brand new rods between knurled steel vise jaws seemed a bit harsh, so my idea was to use C-clamps to squeeze each rod between my dining room table and a 2 x 4. Am I a bachelor? You bet.

Camshaft

A Summit Racing Stage 2 Turbo LS hydraulic roller camshaft suited this engine nicely. Rated at .600-/.575-inch lift and 226°/230° duration at .050-inch lift, I wouldn’t have to worry about piston-to-valve clearance (although I did check) and I could use a stock 4L80E torque converter. I installed the cam straight up and verified it with a degree wheel. I also installed a set of Summit Racing roller lifters and new lifter guides.

Other Stuff

I finished up the short block with the oiling system—a Melling standard volume/high-pressure oil pump and pickup, a Chevrolet Performance windage tray, and a factory truck oil pan. I also added a new ICT Billet valley cover and factory front and rear main seal covers. I had to clearance the front cover to fit the Summit Racing double roller timing set. Some aftermarket covers clear without modification. A few coats of Dupli-Color gray primer and Chevrolet Orange paint and the short block was ready to go.

Top End

On the top end, I chose to stick with the stock 317 cylinder head castings. Not only do they meet my budget, their larger combustion chambers are more boost-friendly, especially on pump gas. My calculated compression ratio with the 71cc chambers and the ICON FHR flattop pistons is around 10:1.

I did freshen up the heads with new Melling intake and exhaust valves and new 1.290-inch beehive valve springs. The springs came in a kit with the Summit Racing Pro LS camshaft so they’re perfectly matched. They even included new valve seals and locks.

I also used Summit Racing’s Pro LS Upgraded Rocker Arms. The all-new cast steel rockers have a captive bearing design with a bearing steel trunnion that replaces the uncaptured factory bearing and powdered metal trunnion. This design can handle higher-lift cams and high-load valve springs without spitting the needle bearings into the crankcase.

As I stated before, I wasn’t too worried about piston-to-valve clearance with the Pro LS camshaft, but worried enough to measure it anyway. While there is nothing radical about this engine, it does have a more aggressive cam, a new piston/rod combination, and surfaced block and heads. Clearance measured over .100-inch, which is plenty.

Since I installed a new cam, I double-checked pushrod length using an adjustable pushrod. It measured at 7.35 inches. Since I wanted .050-inch of lifter preload, I factored that in and ordered 7.400-inch long Summit Racing HDR chromoly pushrods.

I secured the cylinder heads to the block with Summit Racing OEM replacement head bolts and .050-inch thick Mahle head gaskets. While using new factory head bolts might raise an eyebrow or two, let me explain. I built this engine just after COVID when it was hard to get parts, and I couldn’t find upgraded head bolts anywhere.

The other part of my reasoning was budget. Since this wasn’t a race engine, I didn’t think head studs were necessary, even with a turbo. At eight PSI of boost I wasn’t too worried about lifting head gaskets. I’ve had fun doing full throttle pulls merging onto the interstate, but otherwise I tend to keep my foot out of the throttle.

Air, Fuel, and Spark

I used a factory GM truck intake manifold and throttle body, but upgraded to Holley 80 lb.-hr. injectors (we list 76 lb.-hr. injectors in the parts list). I also used OEM replacement coils and NGK spark plugs to handle the ignition.

Everything is controlled by a Holley Terminator X MAX engine management system. It handles fuel and ignition as well as the 4L80E transmission that’s going in the dually. It also has boost control functions plus nitrous control should I decide to completely get carried away and add a fun bottle.

Squeezing the Air

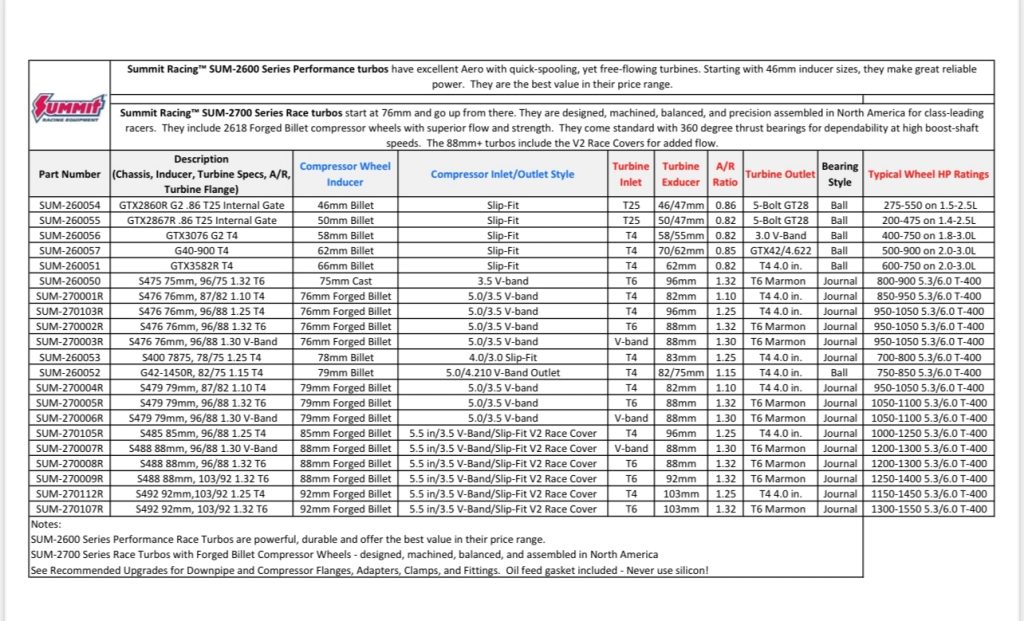

The wow factor of this build rightfully belongs to the Summit Racing S475 turbocharger. Featuring a 75mm inducer and 96mm exducer, this turbo could fulfill any high-boost vision I had for the engine. A VS Racing 44mm wastegate controls boost pressure.

I fabricated the hot and cold sides of the turbo system with Summit Racing and Vibrant Performance tubing. I did not include an intercooler. Going back to how the truck would be driven, an intercooler was not necessary. Keeping a keen eye on intake air temperatures and running a minimum of 93 octane fuel have been sufficient to keep detonation at bay.

The Final Product

So how did this engine perform? To be honest, it’s awesome. I had my fair share of gremlins to take care of when installing the engine in the truck, but it wasn’t long before I was doing hard pulls down the street. The best part is probably seeing peoples’ reaction to a big ol’ dually truck with a four-inch exhaust pipe sticking out of the front fender zoom past them.

Short Block Parts List

Scat Pro Sport H-Beam Connecting Rods SCA-6612521

ICON FHR Series Piston and Ring Set UEM-SRE10037

King Bearing HP Series Main Bearings KGB-MB5013HPSTDX

Summit Racing™ LS Main Cap Bolt Kit SUM-910229

Clevite Camshaft Bearings CLE-SH2125S

Melling Standard Volume/High-Pressure Oil Pump MEL-10295

Chevrolet Performance Windage Tray NAL-12558189

Summit Racing™ Billet Timing Set SUM-G6614R-B

PowerBond OEM Replacement Harmonic Balancer PBB-PB1190N

ACDelco Genuine GM Parts Harmonic Balancer Bolt NAL-12557840

ICT Billet Lifter Valley Cover ICB-551629

Summit Racing™ Freeze Plugs SUM-G1584

Camshaft and Valvetrain Parts List

Summit Racing™ Pro LS Camshaft and Spring Kit SUM-8706-1

Summit Racing™ Lifter and Guide Kit SUM-HTLSKIT1

Summit Racing™ Camshaft Retainer Plate SUM-150106

Summit Racing™ Cylinder Head Bolt Kit SUM-910210

Melling Intake Valve, 8 required MEL-V2000

Melling Exhaust Valve, 8 required MEL-V1935

Summit Racing™ Pro LS Upgraded Rocker Arms SUM-141556

ACDelco GM Genuine Parts Rocker Arm Stand NAL-12552203

Summit Racing™ HDR Thickwall Chromoly Pushrods SUM-14957375

Trick Flow® Steam Line Hose Kit for GM LS TFS-306SB601K

Induction, Ignition, and Engine Management Parts List

Holley EFI Terminator X Fuel Injectors, 76 lbs.-hr. HLY-522-768X

Summit Racing™ High Output Ignition Coils SUM-850501B

Holley Terminator X MAX Engine Management System HLY-550-928

Dorman Replacement Intake Manifold RNB-615-183

ACDelco GM Genuine Replacement Parts Throttle Body ADO-12679524

NGK Spark Plugs NGK-3346

Turbocharger and Plumbing Parts List

Summit Racing™ Performance 75mm Turbocharger SUM-260050

VS Racing 44mm Wastegate VSG-VSR44WG

Hooker LS Turbo Exhaust Manifolds HOK-8510HKR

ICT Billet Turbocharger Oil Pan Adapter Flange ICB-551608

Summit Racing™ Turbocharger V-Band Discharge Flange SUM-260062

Summit Racing™ 3.5″ Silicone Hose Coupler SUM-294013

Summit Racing™ Aluminum Air Intake Tubing SUM-294513

Summit Racing™ Aluminum Air Intake Tubing, 180° SUM-294523

Summit Racin™ Exhaust Tubing Mandrel Bend SUM-623011

Vibrant Performance Aluminum Tubing VPE-2977

Green Filter High Performance Air Filter GRE-2384

Gaskets and Sensors Parts List

Mahle Original Cylinder Head Gasket MAH-54983

ACDelco GM Genuine Parts Oxygen Sensor ADO-213-3632

ACDelco GM Genuine Parts Knock Sensor ADO-213-3521

ACDelco GM Genuine Parts MAP Sensor ADO-213-4760

BTR Header Gasket BTC-BTR17944

Summit Racing™ Water Pump Gaskets SUM-G2624

Summit Racing™ Front Cover Gasket SUM-G2625

Fel-Pro Rear Cover Seal Gasket FEL-BS40640

Summit Racing™ Valley Cover Gasket SUM-G2626

Misc. Parts List

ICT Billet Alternator/Power Steering Bracket Kit ICB-551778LS0-3

Dupli-Color Engine Enamel Chevy Orange Paint SHW-DE1620

Dupli-Color Engine Enamel Gray Primer SHW-DE1612

Comments