This Going Pro 5.3L buildup had one goal in mind—making 1,000 hp!

Naturally, we would be using boost, but before we could add said boost from our ProCharger, we had to have a suitable base motor. While the 1,000 hp mark was the goal, the motor was also designed to serve as a reliable driver (though not a daily). As a side note, the motor was also destined to look the part, given it would be on display at the upcoming SEMA Show.

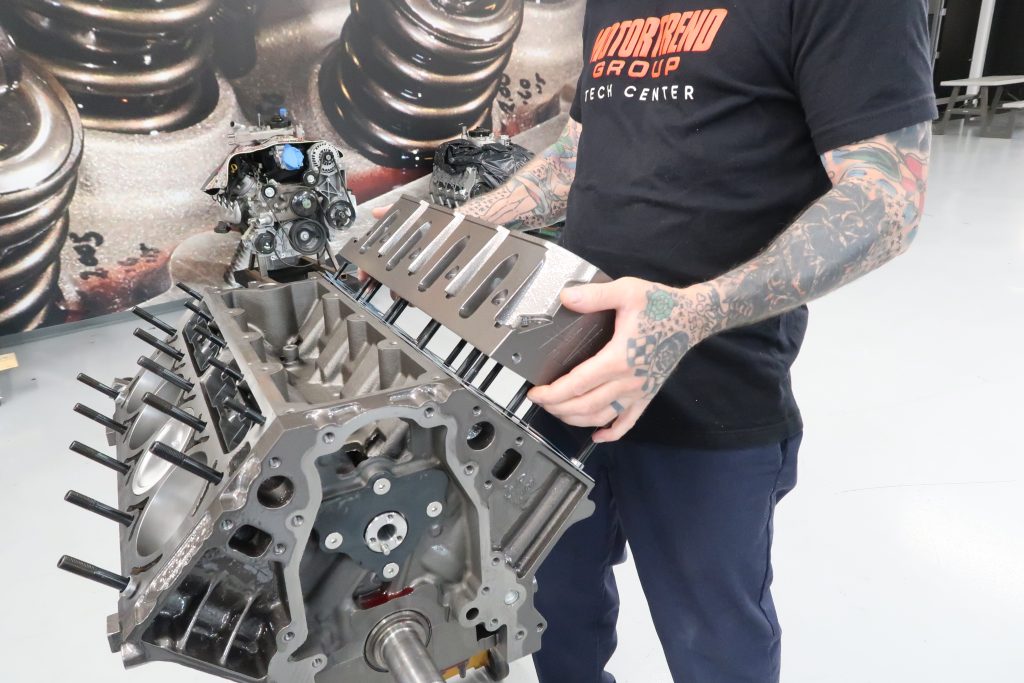

Given the multi-tiered goal, the 5.3L build started with an ATK High Performance Engines Boost-Ready short block.

The first power producing modification for the boosted build was actually displacement, as the LM7 iron-block punched out to 3.903 inches. This over bore stepped displacement up from 5.3 liters to 5.7 liters. When it comes to power production, bigger is always better.

Plus, because they look identical, you can always tell them it’s a 5.3L, or if you are feeling extra deceptive, just a 4.8L!

To ensure strength, the short block featured a stock crank combined with Wiseco forged, dished (-11cc) pistons and SCAT, forged, I-beam rods. With the short block completed by ATK, it was time for the power producers.

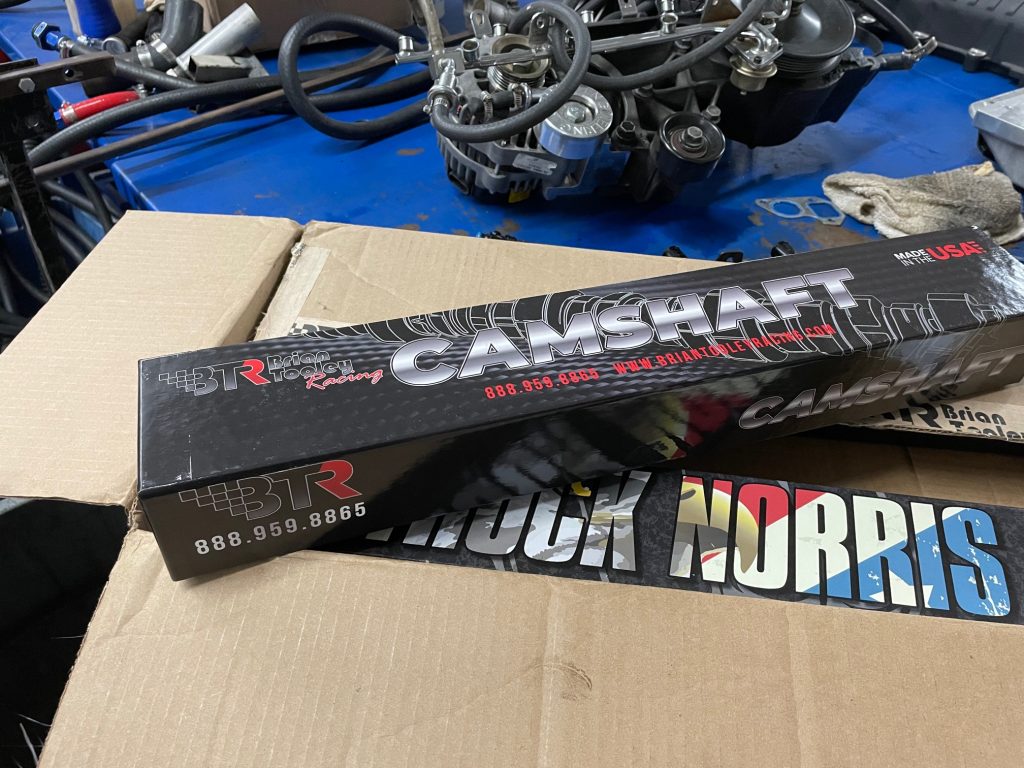

Since pressurized power is always a function of the naturally aspirated power plus boost, we made sure the 5.7L combo offered plenty of power prior to pressurization. The ATK short block was combined with a blower-specific cam profile from Brian Tooley Racing. The dedicated blower cam featured a .613/.596 lift split, a 227/244 degree duration split, and a 115 degree LSA. We were excited about seeing it in action under boost.

The BTR cam was combined with a set of AFR Mongoose cylinder heads. Thanks to full CNC porting and a 2.02/1.60 valve package, the CARB-legal head package flowed over 300 cfm, or more than enough to feed our relatively mild 5.7L.

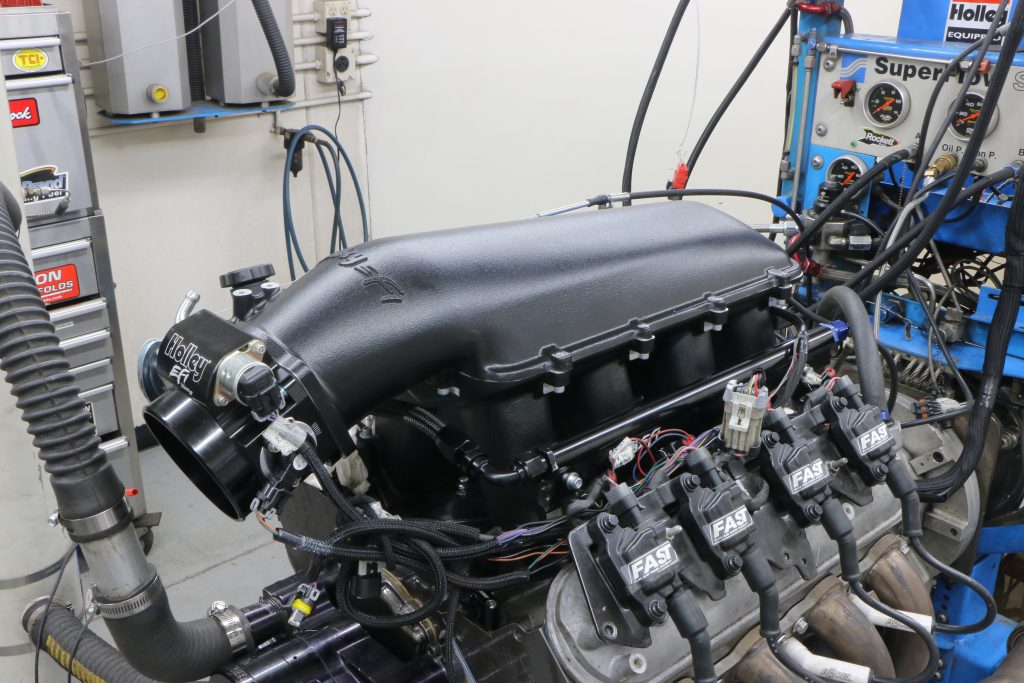

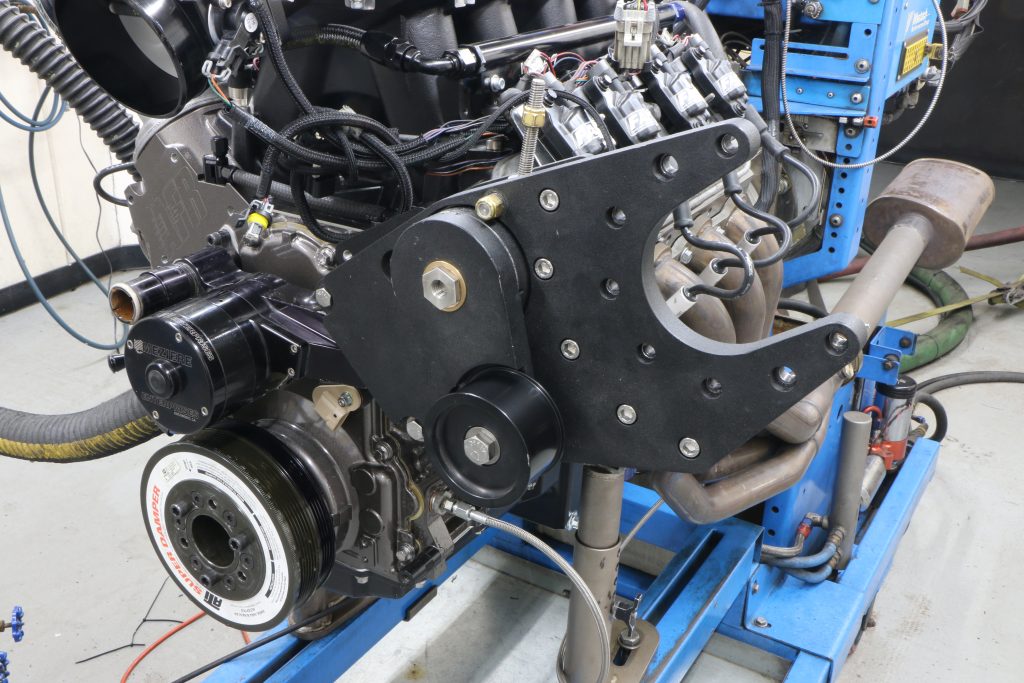

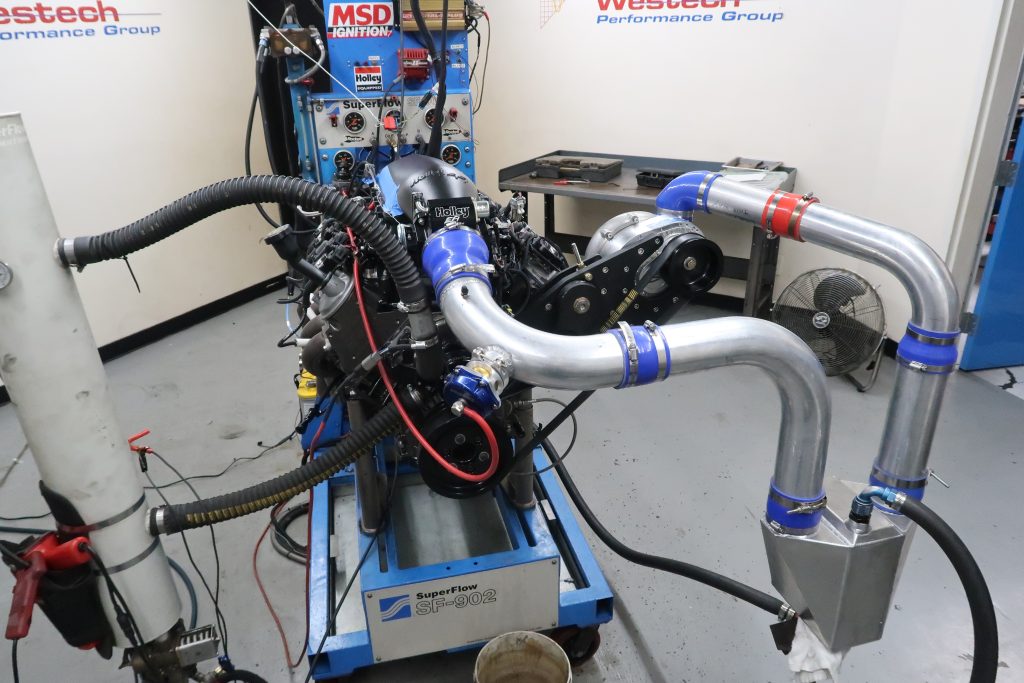

The finishing touches included a Holley Hi-Ram intake with matching 105mm throttle body. Holley also supplied the HP management system and 83 pound injectors. After all, the supercharged LS would need plenty of fuel once we added boost.

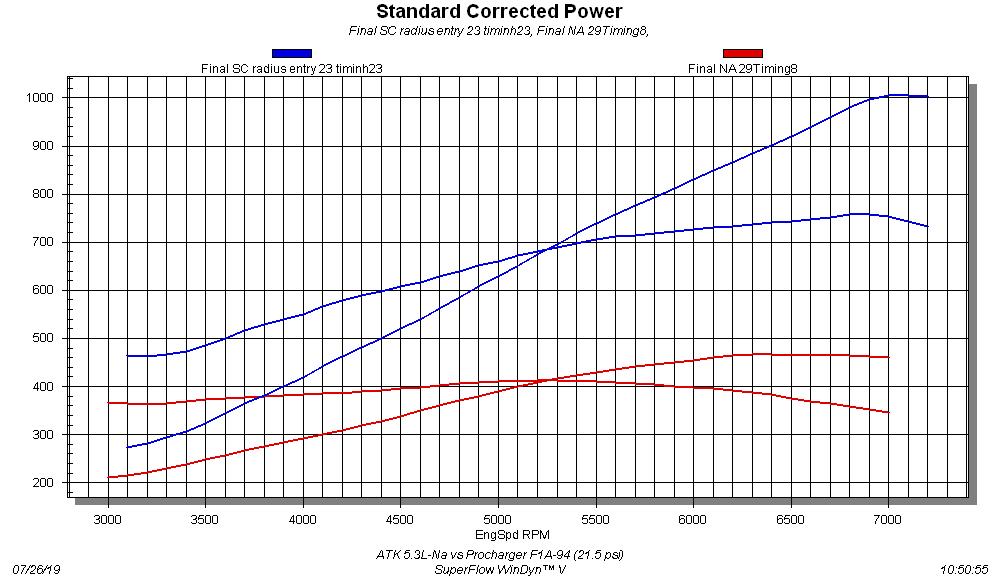

Prior to installation of the Procharger centrifugal supercharger, the motor was run in naturally aspirated trim. Equipped with 1-7/8 inch Hooker long-tube headers (and mufflers), the low-compression 5.7L produced 466 hp at 6,400 rpm and 412 lb.-ft. of torque at 5,200 rpm.

Now it was officially time for some positive pressure!

Adding the ProCharger Supercharger

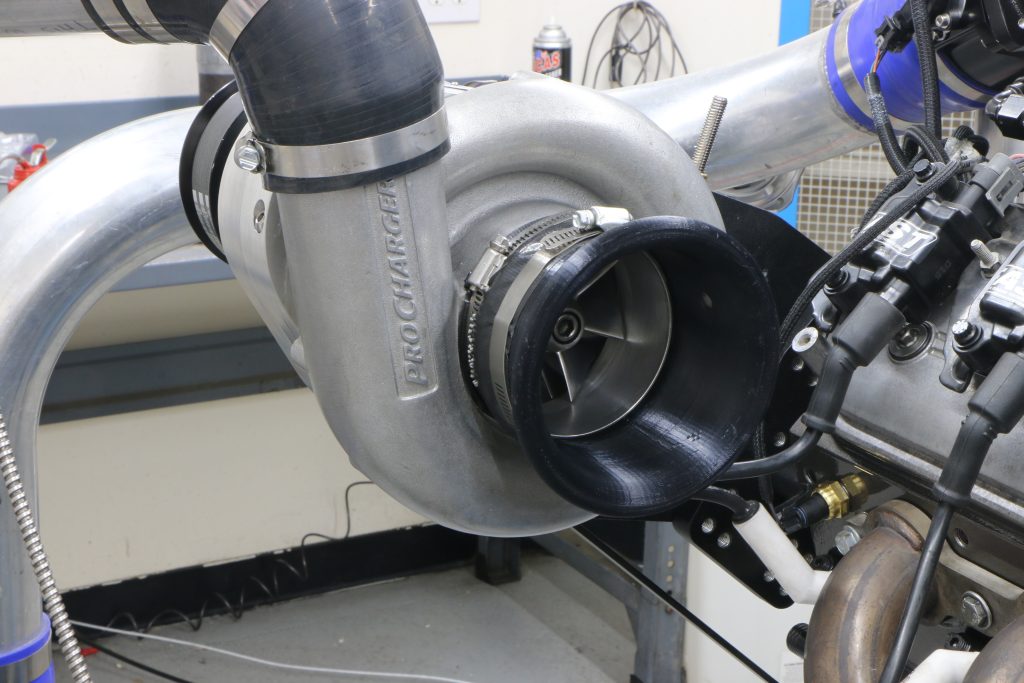

Boost for the 5.7L was supplied on the engine dyno by a ProCharger F1A-94 supercharger kit.

We specified “on the dyno” here since the motor received a different blower kit once installed in the vehicle. On the dyno, we wanted to push the motor (slightly) harder, and the fitment in the vehicle required a reverse rotation kit from ProCharger. This simply made life easier on the dyno for

testing, especially if we had to run multiple blower pulleys to reach our target of 1,000 hp!

As it turned out, we nailed the pulley size on the first try, but we did resort to running a radiused air entry (see photo) on the F1A-94 to reach the 1,000-hp mark. In truth, the F1A-94 could support another 200+ hp on the right combination, and since we were nowhere near the rpm limit of the impeller, we will utter the words of every racer: There was plenty left in the combination.

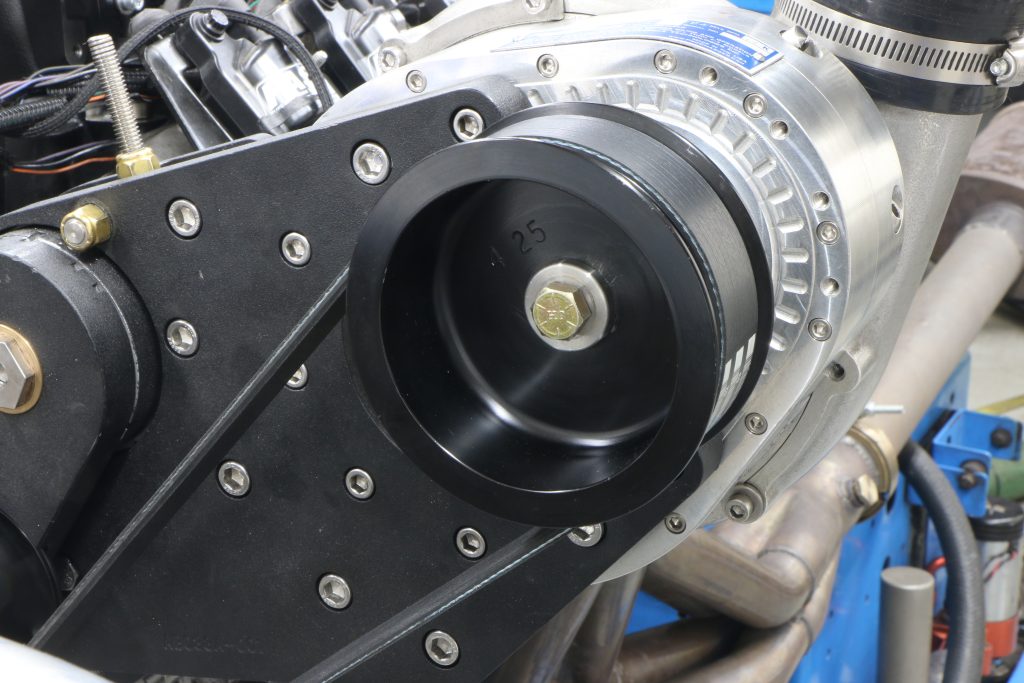

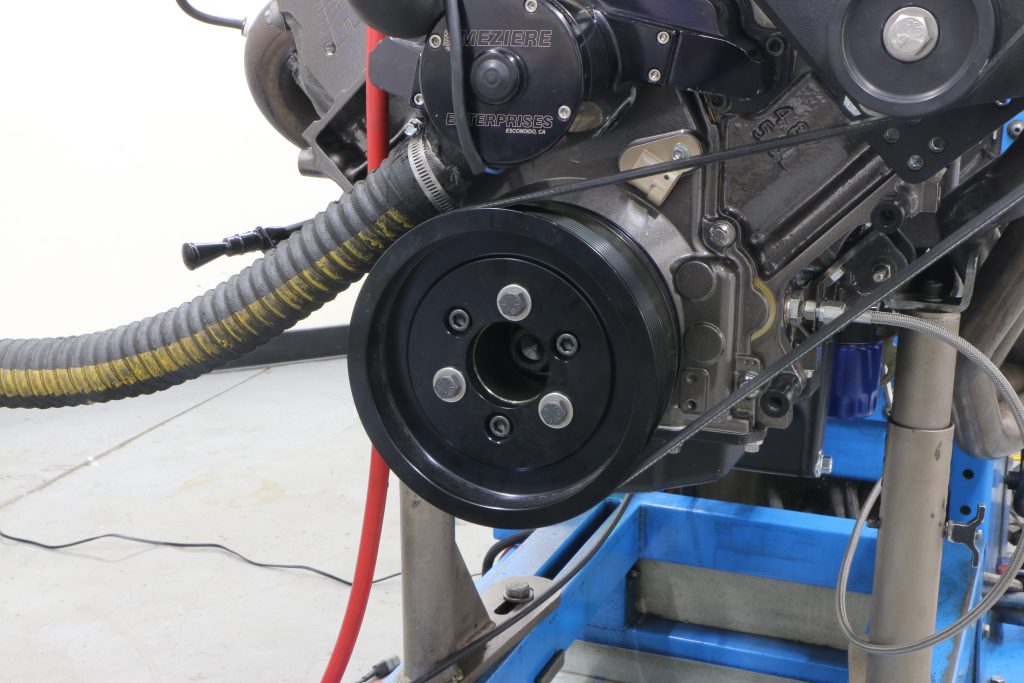

The F1A-94 was installed onto the 5.7L using the supplied mounting kit. The blower was configured with a 4.25 inch blower pulley and combined with a 7.75 inch crank pulley. Installation of the crank pulley required both the use of an ATI Super Damper and drilling the crank for a crank dowel (see photo). This ensured the normally press-fit damper did not spin on the crank when subjected to the extra load of the supercharger.

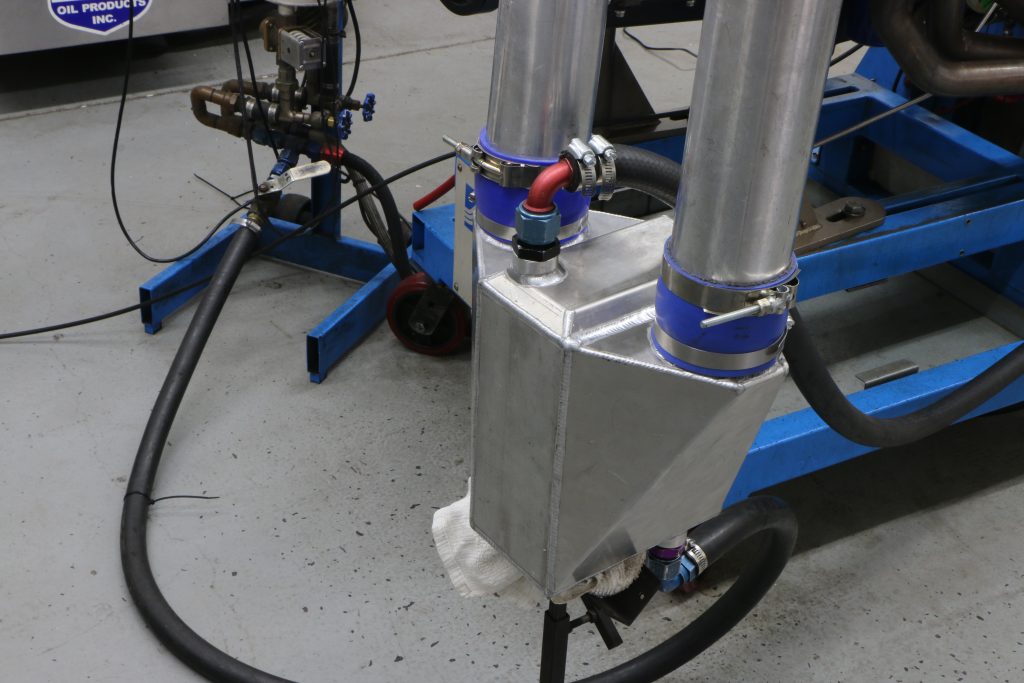

With the pulleys in place, and the blower ready to supply boost, we elected to install an air-to-water intercooler in the system. Given the elevated boost pressure required to reach our power goal, the intercooler was deemed a necessity.

ProCharger supplied one of their air-to-water intercooler systems. Having exceeded 1,300 hp previously with this core, it was more than adequate for our little 5.7L. The core was plumbed with (cold-side) aluminum tubing from CXRacing. The air-to-water core was fed ambient (94-degree) dyno water, though additional power could certainly be had with ice water. The efficient intercooler dropped the inlet air temps from 287 degrees to a maximum of 115 degrees.

Once we added the radiused air entry and all the tuning was completed under boost, the supercharged 5.7L pumped out a peak of 1,005 hp at 7,100 rpm and 758 lb.-ft. of torque at 6,900 rpm. These power numbers came at a peak boost reading of 21.5 psi using 114 octane race fuel (with 11.5:1 A/F and 21 degrees of total timing at the power peak). E85 would have offered even more power.

For those keeping score, the Procharger F1A-94 supercharger improved the power output of the 466 hp 5.3L by 539 hp!

Everything really is better with boost.

JPL love anything from Mr Holdner