Brake tech is a very complex and nuanced topic, so we asked the experts at Alcon Brakes to help us clarify and expand on some frequently asked questions in the braking universe.

Today, they’re comparing the pros and cons of radial- vs. axial-mount brake calipers and explaining why OEs and performance aftermarket companies use each type in certain situations. This article’s a good read if you’re shopping for the the best brake calipers for your specific vehicle application.

***

Story Summary Overview

- Distinction rests in each caliper’s mounting method

- For axial calipers, the mounting bolts go in from the side, on radial calipers, they go in from the top

- Axial calipers are the most common, particularly in floating caliper designs

- Radial calipers are popular in performance applications, particularly with opposed piston designs

***

The Difference Between Radial- & Axial-Mount Brake Calipers

Calipers are generally mounted to the upright in one of two ways: radial or axial.

What Are Axial-Mount Calipers?

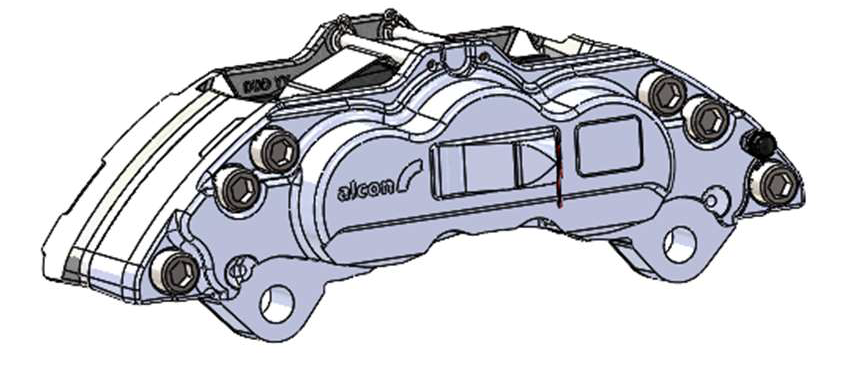

The most common brake caliper design is axial (or lug) mounted where the mounting hole centers are in-line with the disc centerline.

This makes very good sense for a floating caliper as the bolts run parallel to the slide pins and hydraulic pistons. Everything will then be secured in line with the caliper’s movement. When pressure is applied, the caliper will react and slide without tilting.

It’s not so straight forward with opposed piston (fixed) calipers. When pressure is applied to the disc both caliper halves will deflect, pushing them away from the disc. With having the lug mounting face parallel to the disc face, the reaction in the caliper inboard half of the housing will try to push away and, being restricted at the lugs, can cause the caliper to tilt.

The greater the distance between mounting holes and disc effective radius, the greater the affect of tilting that may occur.

If the caliper stiffness in the area between lugs and main body is good, this tilting can be negligible and

have no noticeable effect.

What Are Radial-Mount Calipers?

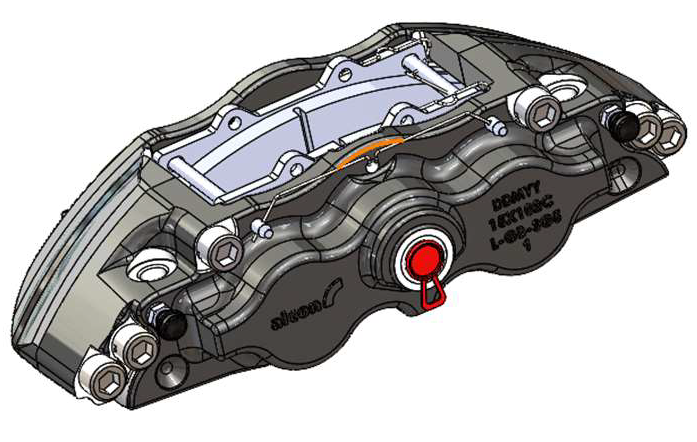

A radial mount caliper has the mounting face in-line with the piston centerline, which prevents tilting, reducing taper wear and increasing overall stiffness.

Opposed piston calipers used in motorsports, racing, and on many high performance road cars are often radial-mount, as they help increase stiffness and eliminate tilting where weight is important and the additional material required to stiffen the lugs would increase unsprung mass.

There is another advantage with radial mount calipers.

Already tooled, generic calipers can be used on low volume applications or in upgrade kits, where they are easier to adapt to fit exiting knuckles through the use of a bespoke adapter bracket.

Comments