I have a 1970 SBC 350 in a 1968 Camaro. It’s all old-school with a flat tappet hydraulic cam, carburetor, mechanical cooling fan, and other details. Can the cam timing be checked without disassembling the front of the engine and taking the heads off? I didn’t build the engine and want to see if the cam is advanced or retarded. Thanks.

T.T.

The answer is yes, but with an important caveat. I will assume from your question that the engine is equipped with factory iron heads since you referenced an ‘old school’ small block. Most factory heads will allow a spark plug-style screw-in piston stop to contact the piston. This is important because a physical stop to piston movement is necessary to find Top Dead Center (TDC). You cannot assume TDC just by placing the piston at the top of its travel. This is the critical step in degreeing your cam.

Let’s get into some details about how to find TDC. If you have a short block with the heads off and rotate the crankshaft with a degree wheel and pointer, you will notice that when the piston reaches TDC the crankshaft will move several degrees before the piston begins to move back down the cylinder. This means if you do not use a piston stop, you are guessing at the true position of TDC. This guess could be off by as much as two or three degrees, which makes all subsequent measurements off by this same amount. But you won’t know that because the true position of TDC is an estimate.

Because of this, it is essential to use a piston stop for establishing true TDC and degreeing the camshaft. This can be done with either the heads on or off. Assuming the piston stop will work, it will stop the piston a few degrees on either side of TDC. Once you set your degree wheel so that it reads the same number of degrees on both sides of TDC, then you know for sure that you have established true TDC with the degree wheel.

Once this is established, you can then go through the process of measuring the intake centerline. In previous tech columns we’ve run through the details of how to read a cam card, but the short version is if the cam is ground with advance like most street cams are, then the intake center line will not be the same number as the lobe separation angle (LSA). As an example, if the LSA is machined at 112 degrees but the intake center line is listed as 110 degrees, then the cam has been ground advanced by two degrees. If both the LSA and intake center line are the same number, the cam has not been ground advanced.

Once you have established TDC, the easiest way to find the intake center line is to use your dial indictor on the intake lobe to find the highest lift created by the lifter. With this position, zero the dial indicator. The cam lobe may indicate max lift for several degrees. This is normal and will not affect the readings.

With the dial indicator showing zero, now turn the engine backward to roughly 0.100-inch before max lift. Now turn the engine clockwise until the indicator reads 0.050-inch before max lift. The reason we do it this way is to remove any of the slack or backlash in the cam drive before we reach the 0.050-inch inch mark. Now write down the number indicated on the degree wheel. Let’s say the number is 160 degrees before top dead center (BTDC).

Now, rotate the engine clockwise again until the dial indicator shows 0.050-inch on the closing side of the lobe. Record the number indicated on the degree wheel. Let’s say that this number is 60 degrees. Add the two numbers together (160 + 60 = 220). Divide the sum this by two and we have 110 degrees. This is the position of the intake centerline.

Frankly we would not stress over a one degree difference in either direction. If your numbers come up as 109 degrees (one degree advanced) or 111 degrees (one degree retarded) this will be okay. If you were building an NHRA Competition Eliminator engine or other race engine, you might consider repositioning the cam. But for the rest of the world a tiny change like this will not noticeably affect engine performance.

If you want to determine if the cam is advanced, you will need to find the exhaust centerline and compute the lobe separation angle. Let’s use the 110 degree intake centerline figure and assume the exhaust is also 110 degrees before top dead center (BTDC). Adding those two together and dividing by two will produce 110 degrees of lobe separation angle (LSA). Since the LSA and the intake centerline numbers are the same, this means the cam is not advanced.

Generally, what you will see is the intake centerline will be around 106 degrees with an LSA of 110 degrees. This means the cam was likely machined advanced by four degrees.

Doing this procedure requires some specialty tools—a degree wheel, a spark plug-style piston stop, a dial indicator and magnetic base, and a way to turn the engine over both forward and backwards. This is important since you will need to turn the engine backward to find TDC and and the intake centerline. You must do these movements by hand. Do not use the starter motor, especially when using the piston stop for obvious reasons.

With the engine in the car, you can use a simple tool called an engine rotation adapter. It bolts to the three-bolt flange on the balancer and allows you to turn the engine in any direction using a ½-inch drive breaker bar. There are other tools, but this is inexpensive and will do the job.

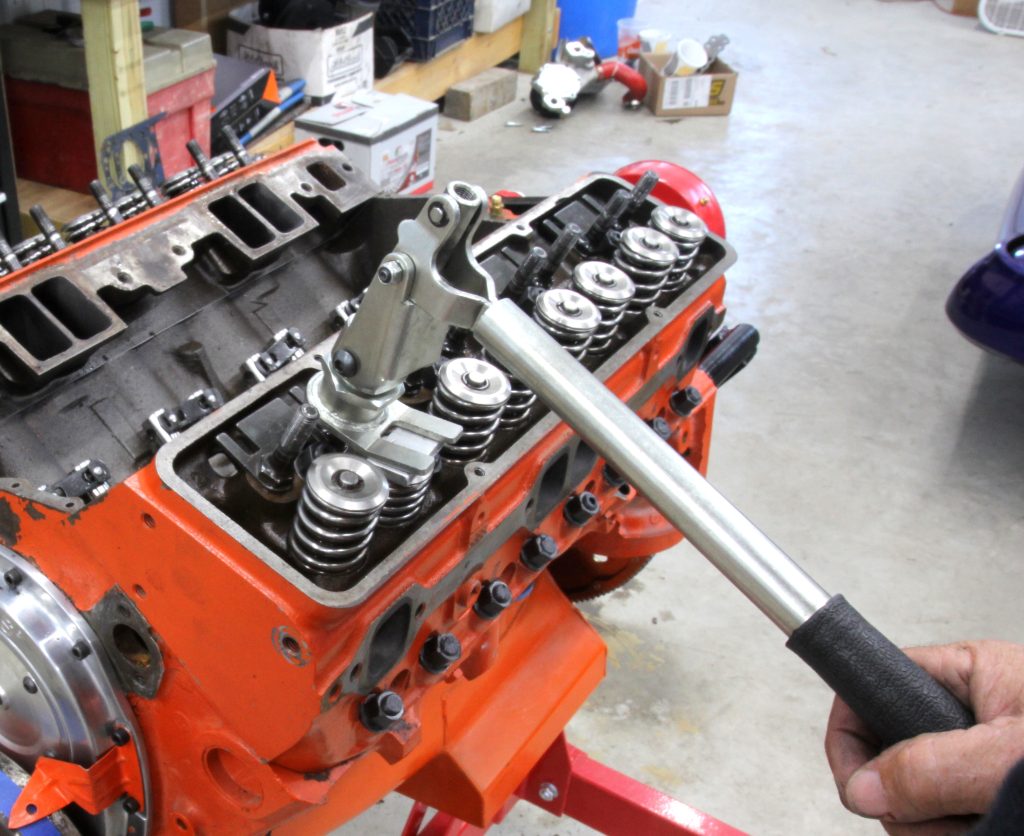

If a spark plug-style piston stop will not work because it doesn’t contact the piston, there is a way to create one. Summit Racing sells a slick valve spring compressor tool that locates on a rocker stud to remove valve springs with the heads in place. This tool uses a lever to compress the retainer to remove the locks. I’ve used this tool with a small steel plate placed over the valve tip so that the tool will push the valve down roughly a half-inch. The tool’s over-center function will hold the valve in a locked position. You can now use this locked valve as a piston stop. You must be very careful moving the piston up to contact the valve so that you don’t bend the valve, but I’ve done this several times and it works very well.

Parts List

Proform Engine Rotation Adapter PRO-66782

Summit Racing™ Valve Spring Compressor Tool SUM-906784

Comments