In the vast world of the automotive aftermarket, enthusiasts have explored the boundaries of vehicle modification. From the simplest bolt-on street cars to Top Fuel dragsters, we love the idea of adding horsepower, cornering harder, or stopping faster than before.

Any time you spin wrenches, you’re likely loosening and tightening fasteners. For some, nuts and bolts are an afterthought, while others take great pride in hitting exact torque specifications and/or having the hardware look as good as any other part on your car, truck, motorcycle, or watercraft.

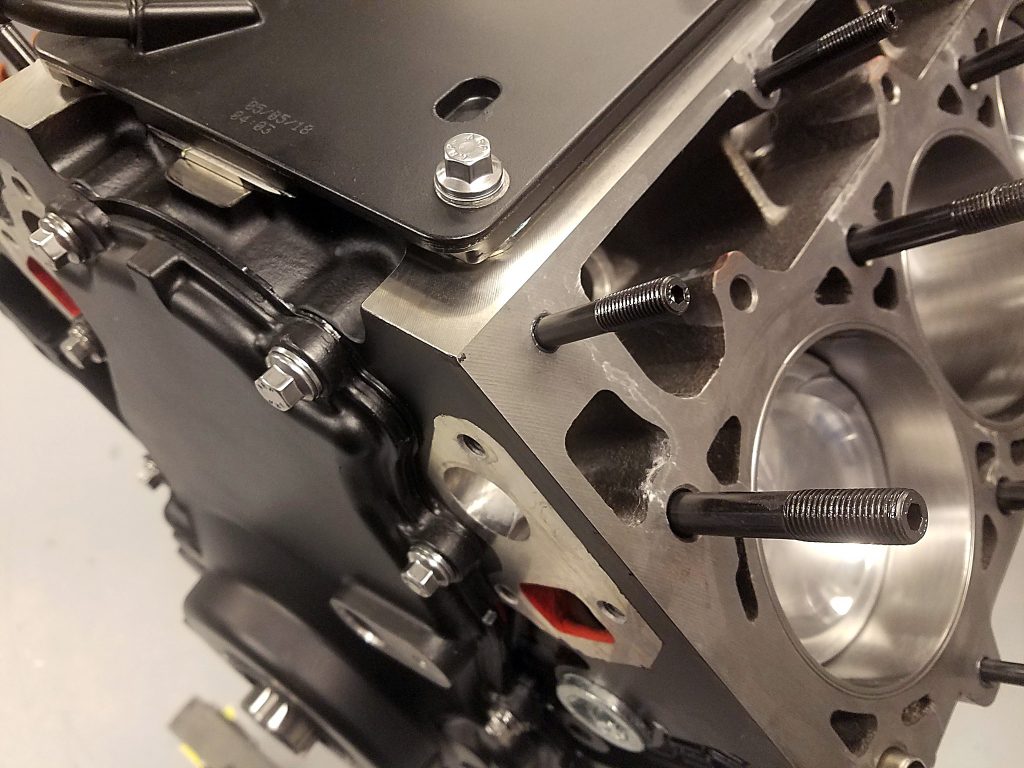

Unlike a welded or riveted connection, fasteners allow parts to be easily and quickly removed and replaced, should the need arise. This makes it possible to disassemble, reassemble, and swap things like the intake manifold or cylinder heads using the same—or improved—hardware.

As you’re aware, the hardware we call fasteners come in different types, sizes and even materials. Common materials are iron, stainless steel, nickel, brass, aluminum and titanium. Fasteners for automotive use often include nuts, bolts, screws and studs, but there are others, such as clips, locks, Pip Pins, Dzus fasteners, camlocks, spring hooks, over center locks, and more.

Enthusiasts often consider weight, strength (load, tension, heat and/or force), and cost when choosing a fastener. And the type of hardware can change depending on the task, too. Meaning, the hardware you select to attach a fender may be different than the hardware used to hold the harmonic balancer to the crank.

“Excluding appearance, there are common considerations in fastener selection whether you’re building a daily driver, a high-performance streetcar or a true race-only vehicle,” said Mike Bowman of ARP. “However, racing tends to increase demand on various assembles with bolted joints. Common considerations are clamp load or shear strength required to get the job done, operating environment such as high temp-high corrosion, reusability and cost and availability.

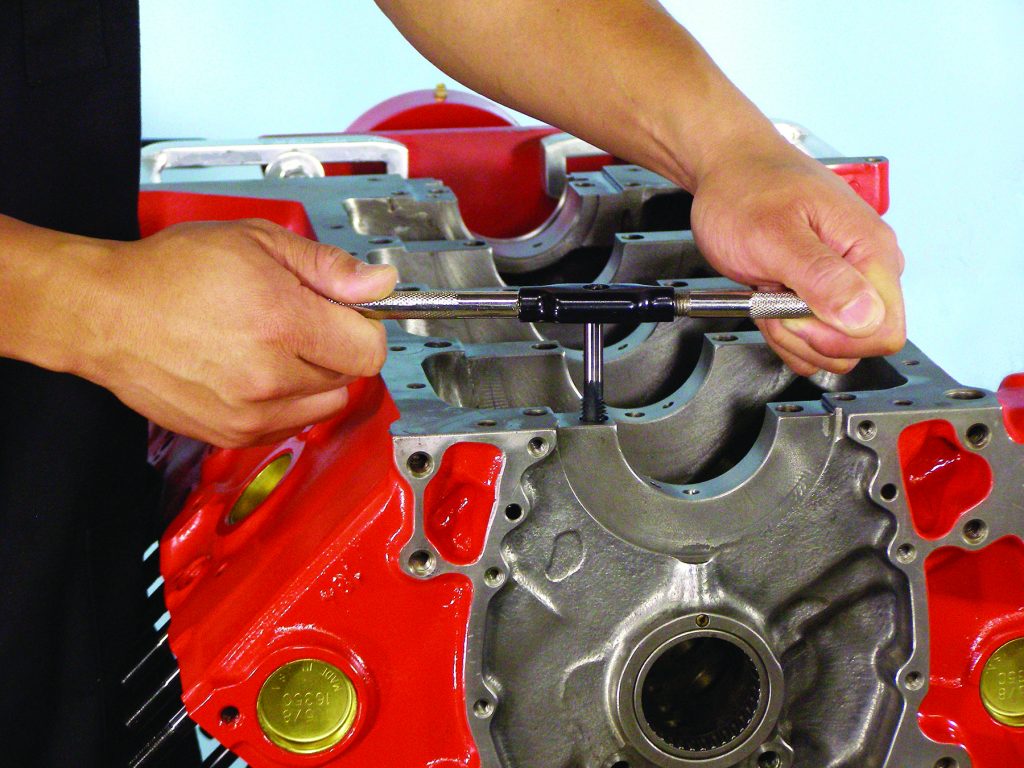

“In race applications you can add: Service interval—is it four or five times a day vs. once a season? As this changes, what type of fastener and installation technique are ideal? Is there a desired safety margin over base calculated requirement? This should also be listed in the common considerations but is more critical in race applications where unforeseen stresses more likely occur. What are the fastener design attributes that ease assembly and disassembly? Examples of this are the use of studs that can hold multiple parts in alignment and reduced or internal wrenching head/nut designs that when used in combination with the right tools can really generate a time effort savings. Finally, studs vs bolts in terms of thread preservation in frequently assemble/disassembled components.”

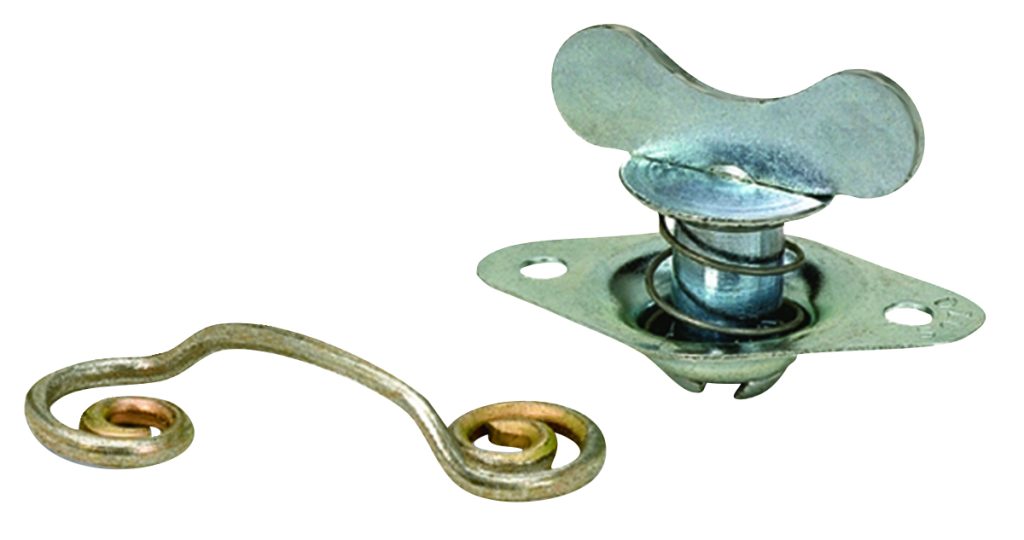

Brett Corriveau, Product Manager at Moroso added, “The finish of the fastener will determine appearance and longevity. For example a black oxide or zinc-plated fastener would hold up longer than raw-finish equivalents based on this decision. In some cases, a stainless fastener would work best for looks/appearance when it is not a structural/load bearing component. Another point for consideration would be whether the fastener is going to be used in a high-maintenance situation, or a one-time assembly component, such as a chassis part. For example, body panels or covers that are removed frequently may be better suited to our butterfly-head quick release fasteners.”

Still, you may be wondering how to determine the correct fastener for the job? Corriveau continued, “Consider the required strength of said fastener, whether it needs to be Grade 5, Grade 8, etc. Next, is the fastener in sheer, like a press-in wheel studs, or in tension, like a valve cover or oil pan bolt? This will help determine if the fastener needs to be a bolt versus a stud/nut. Lastly, the relationship between the fastener and its accessibility around the component is something to consider. For example, many of our fabricated valve covers use pockets around the mounting holes; this limits the size of the fastener and as a result a 12-point nut with a smaller shoulder works best; a normal hex-head bolt would not fit, nor would there be room for a socket.”

Bowman of ARP added, “Figuring out the fitment aspects of a fastener is a straight-forward process requiring little more than some basic measuring skills and a rudimentary level of knowledge of thread identification. But calculating operating loads from scratch is not a simple process. In manufacturing a good fastener that will survive a given application beyond material tensile strength takes consideration of design factors like thermal expansion, relaxation and fatigue mitigation as well as specific manufacturing techniques that can make the difference between winning and losing.”

Complete books have been written on metallurgy, so experience and track history of a given supplier can be a major asset to both the hobbyist and pro racer.

Once you have the best fastener for the job, how should you determine how tight it should be? “This is really a great question,” said Bowman. “Of course there is the obvious answer, follow the manufactures recommendations set forth in the instruction, however, the truth of the matter is that while the manufacture of a high-performance fastener is a somewhat exact science, tightening one, no matter how good the instructions are, isn’t always.”

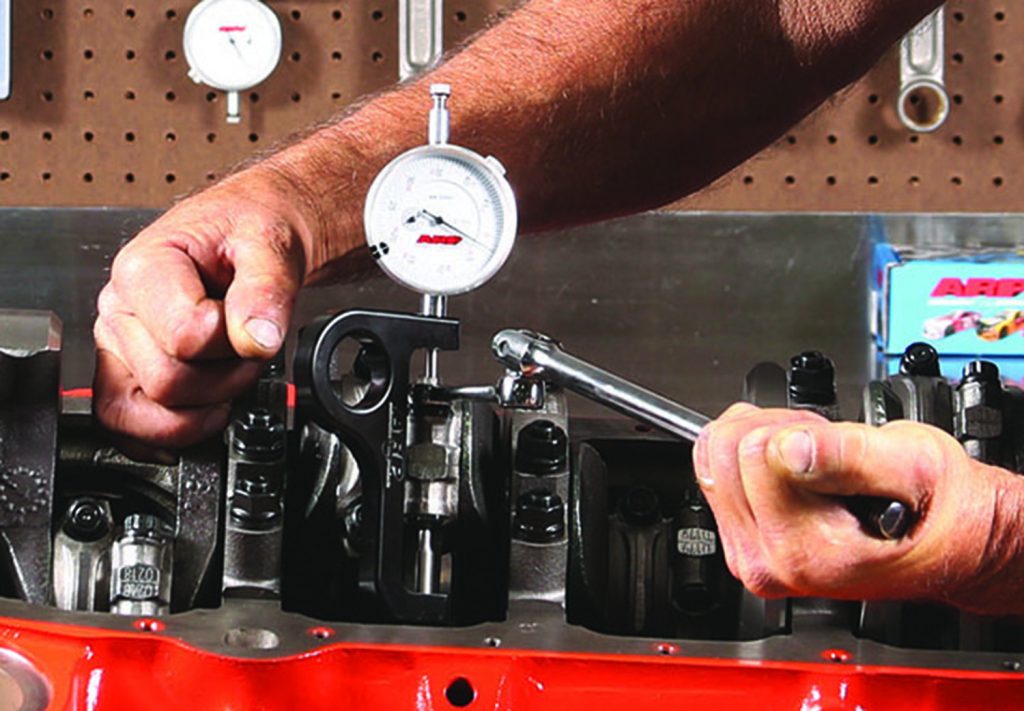

There are fasteners, like rod bolts, where a physical double-ended measurement of elongation can be taken either with a stretch gauge or micrometer and fasteners where some other method of determining when the proper clamp load has been achieved must be used. A double-ended measurement of elongation is extremely accurate. Elongation and clamp force have a direct relationship with each other. However, torque, no matter how good your torque wrench is, and clamp force, do not. There are potentially a few ways of doing a single-ended measurement of a fastener where only one end is accessible. They can be measured ultrasonically, which can be pretty accurate particularly on larger-diameter bolts, but the equipment is expensive and fairly time consuming to use.

Don’t ignore what you’re feeling. If a fastener pulls up to torque very quickly with an abrupt stop, friction could be high. If it pulls very smoothly, but doesn’t have a linear increase in effort, friction is low. Friction comes from two sources, thread and bearing. In some cases, new fasteners benefit from a little extra time spent tightening and then backing off to break in or lap the threads. Fasteners that have been through many assembly/disassembly cycles wear effecting friction one way or the other.

And always inspect used fasteners. Watch the threads for any sign of galling and check dry that they tread together smoothly with no sign of excessive looseness. Look at the bearing surface carefully. Even what looks like very mild metal transfer or smearing on the bearing surface of the nut, washer, or bolt under head can affect load by thousands of pounds. Conversely, a free spinning washer on a smooth spot face can lead to over tightening.

Temperature effects the friction coefficient of the lube in turn effecting load. Heat generally reduces friction. Particularly on cylinder heads the one at a time method generally improves even clamp load fastener to fastener. After tightening the head down in the normal three-step sequence, back each bolt off one at a time and then bring back to finale torque in one smooth continues pull on torque wrench. This isn’t always possible, but in any case, the longer the pull to final torque the better.

Does the term “aircraft grade” or “aircraft hardware” apply to racing? “I would say not really,” replied Bowman. “It’s kind of like calling something deluxe or all natural, there is no clear definition as to what it’s guaranteeing, however, seam and defect-free means something.”

Corriveau added, “Components being used to build or maintain aircraft must go through rigorous QC checks, in addition to being strong, light and corrosion resistant. This translates to dependable parts when used in racing applications. For example, our heavy-duty “T” handle quick release pins are constructed with aircraft-grade aluminum to ensure trouble-free use.”

“When there is something to be gained from a weight savings titanium offer that with reasonably high tensile strength, but at a high price per gram saved,” said Bowman. “However, it does not have as high of tensile strength as other less expensive, but heavier materials that when weight saving isn’t the highest concern are probably a better choice. Probably the best use of aluminum in a fastener would be in one designed to fail as part of a safety mechanism or some kind of bulkhead fastener that’s big and doesn’t need to be very strong, but not as a material for a stressed fastener.”

What are common failures and how can racers avoid them? “A couple common pitfalls include not choosing a high enough grade fastener for the component in question or not properly torquing the fastener for how it is being used,” said Corriveau. “Making sure the fastener is rated for its intended task will help avoid this, as will a regular nut/bolt check around the vehicle. This can consist of a simple check with a torque wrench or complete disassembly and maintenance. Moroso has fasteners for nearly any task. We have corresponding bolt kits and/or stud kits for most of our oil pans and valve covers. We also offer a range of quick release fasteners for body panels, quick pins for wheelie bar and parachute mounts, and a variety of press in extended wheel studs.”

You May Also Enjoy These Articles:

- The “Friction Factor” and Why It Matters

- Rod Bolt Stretch Gauges & How to Measure Bolt Stretch

- Understanding Engine Fastener Types & Materials

- A Guide to Choosing Fasteners for Your Hot Rod

Comments