When it comes time for your engine build, at some point, we are all faced with the same decision.

Your first inclination might be, why did I get myself into this mess? While that is certainly common, the question at hand was one of motivation, more specifically, what form of motivation would be used to power the street, strip or street/strip project?

The choice usually comes down to crate or create?

LS crate motors are very popular for all manner of builds, and for good reason. Crate motors cure many of the problems often associated with complete engine builds, as they are a known quantity and offer reliable and (possibly) affordable performance. There is nothing worse than going to all the trouble to stick in a new motor and finding out it doesn’t work. If you install a GM Performance B15 LSX crate motor, you know it will perform exactly the same as every other B15 crate motor, but for some, that is actually part of the problem. As great as a stock LSX is, for some, stock just doesn’t rock. What happens when you are looking for that little bit (sometimes a LOT) more?

As good as the B15 LSX crate motor is from GM, there are ways to make it even better. Here is one possible route.

For the less adventurous, it is possible to simply purchase the B15 LSX crate motor and be done with it.

For the uninitiated, the B15 crate is GM’s answer to LS guys wanting something stout to add boost to. Judging by the popularity of forced induction on LS applications, this obviously applies to a great many LS owners.

Don’t get us wrong, the B15 crate motor offered plenty of power potential, given the factory specs. The LSX376-B15 (for the technical among us) offered a healthy combination of the 6-bolt, iron GM LSX block. The beefy block was stuffed with a steel crank and forged pistons. The interesting choice was the use of powdered-metal rods, but since we have exceeded 1,500 hp with stock LS rods, they seem to work.

Seemingly designed primarily for blower use, the B15 was equipped with a factory LS9 “blower” cam (0.555/0.560″ lift split, 210/230 degree duration split, and a 122 degree LSA). Mild by aftermarket standards, it was one of the items upgraded in our quest for more power. Topping the 376 short block was a set of 6-bolt LSX-LS3 (rectangle port) heads (2.165/1.600 valves and 68cc chambers). The 9.0:1 compression made it forced induction friendly, and the crate motor was offered sans induction system. The thinking was obviously that the long block be equipped with some type of blower, like the 4.0L Whipple twin-screw used on our application.

We have run this motor in stock trim with a number of different superchargers (roots, centrifugal and twin screw) as well as single and twin turbos, but for this test, we first applied the following upgrades. The factory LS9 cam offered a very smooth (stock) idle and decent power, but we wanted both more chop and power. The valve train was upgraded with a Brian Tooley Racing Stage 3 PD blower cam and matching valve springs.

The LSX B15 came equipped with factory (0.550″ lift) LS6/LS3 style springs, so these were replaced with BTR dual .660 Platinum springs. In fact, these springs were applied not to the stock, as-cast LSX-LS3 heads, but to a set of CNC-ported, AFR Mongoose heads. The AFR heads featured 260cc intake ports, 95cc exhaust ports and peak flow numbers that reached 385 cfm!

Our goal was to have the extra head flow combined with the BTR blower cam specs both improve power and lower the boost pressure. More power with less boost is always a worth-while goal on a blower motor. Less boost equals lower charge temps. The head swap was combined with new Fel Pro MLS head gaskets and ARP head studs (the B15 was supplied with stock head bolts). Stock (LS3 offset) rockers were used along with hardened pushrods from Comp cams.

Now it was time to add some boost.

Though any of a number of blower or turbos could be used to provide boost, we selected a 4.0L Whipple twin-screw supercharger for this B15 build. A number of different blower pulley combinations were run, but we eventually settled on a 4.0 inch blower pulley with the supplied crank pulley from Whipple. Naturally the boosted combo required plenty of fuel flow, so we opted for a set of 1,000cc injectors fed by the Aeromotive brushless dyno fuel pump. The Whipple supercharged was equipped a 102mm throttle body, but could probably use something even larger at this power level.

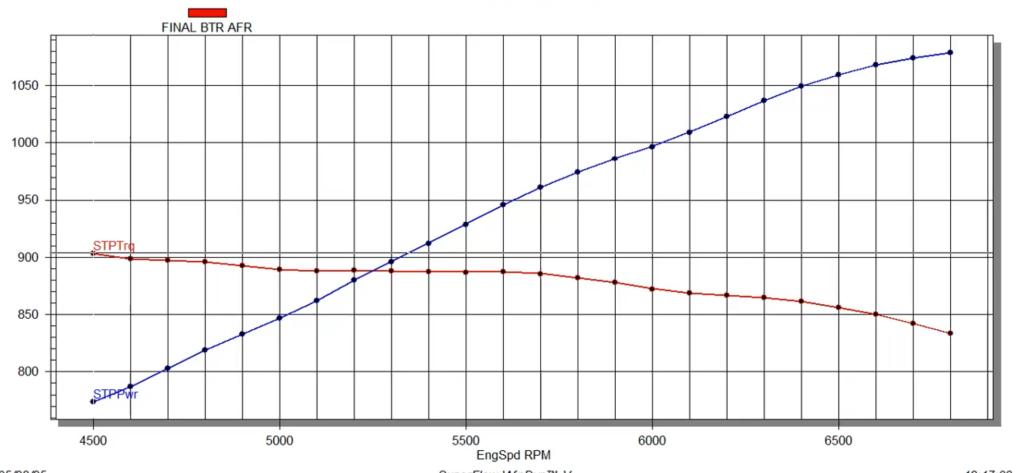

The Whipple blower assembly for the LS included an air-to-water intercooler. For this test, we ran ambient (85 degree) dyno water through the cooler. All of the testing was run using a Holley HP engine management system, a set of 1-7/8 inch. long-tube headers and Lucas 5W-30 synthetic oil (after break in). Run with a Meziere electric water pump, the supercharged B15 crate motor produced peak numbers of 1,081 hp at 6,800 rpm and 902 lb.-ft. of torque at 4,500 rpm. The pulley combination netted a peak boost pressure of 21.2 psi, with a slightly rising boost curve.

With nearly 1,100 hp, this AFR/BTR/Whipple B15 combo would be a handful on the street, but take care when unleashing over 900 lb.-ft. of torque!

Comments