Travel with us way back to 2011, when Ford introduced the 5.0L Coyote to replace the 4.6L 3-valve.

After the demise of the 2003-04 Terminator Cobra, Mustang owners were limited to the Shelby offerings if they were looking for honest GM-killing power. Lucky for enthusiasts, Ford stepped in to fill the performance void by offering the new 5.0L Coyote motor.

Though it lacked the boost we loved so much in the 2003-04 Cobras, the new motor offered some impressive power. Thanks to things like the hike in displacement, variable cam timing and revised intake design, the power output of the 5.0L surpassed the previous 4.6L three-valve by more than 100 horsepower! That was a significant jump in power, but one that was necessary to keep pace with the oversized offerings from GM and Dodge.

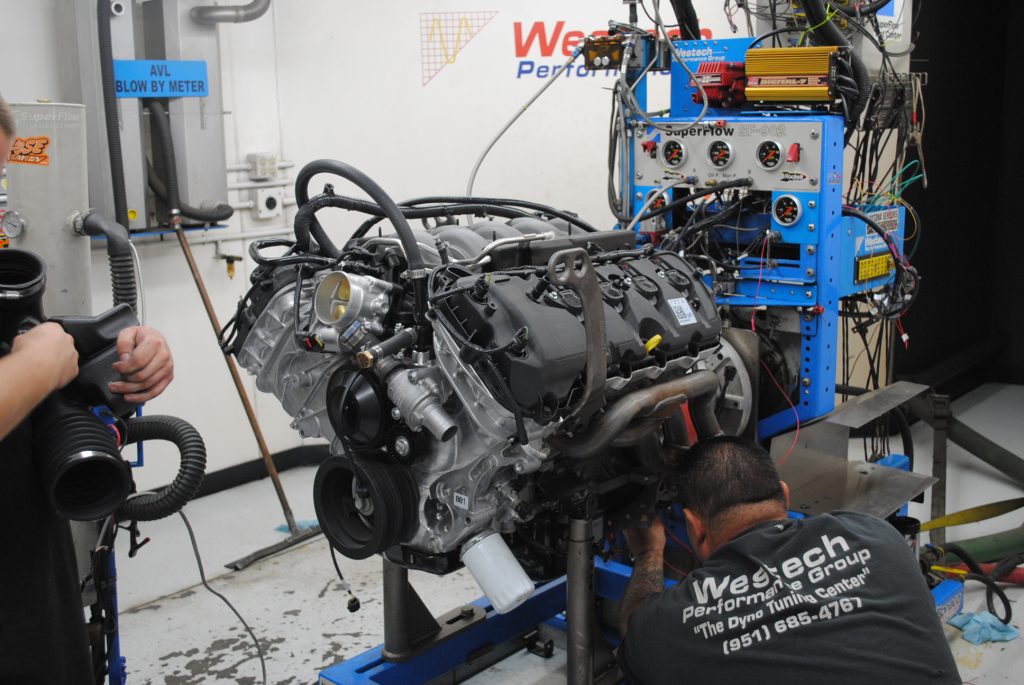

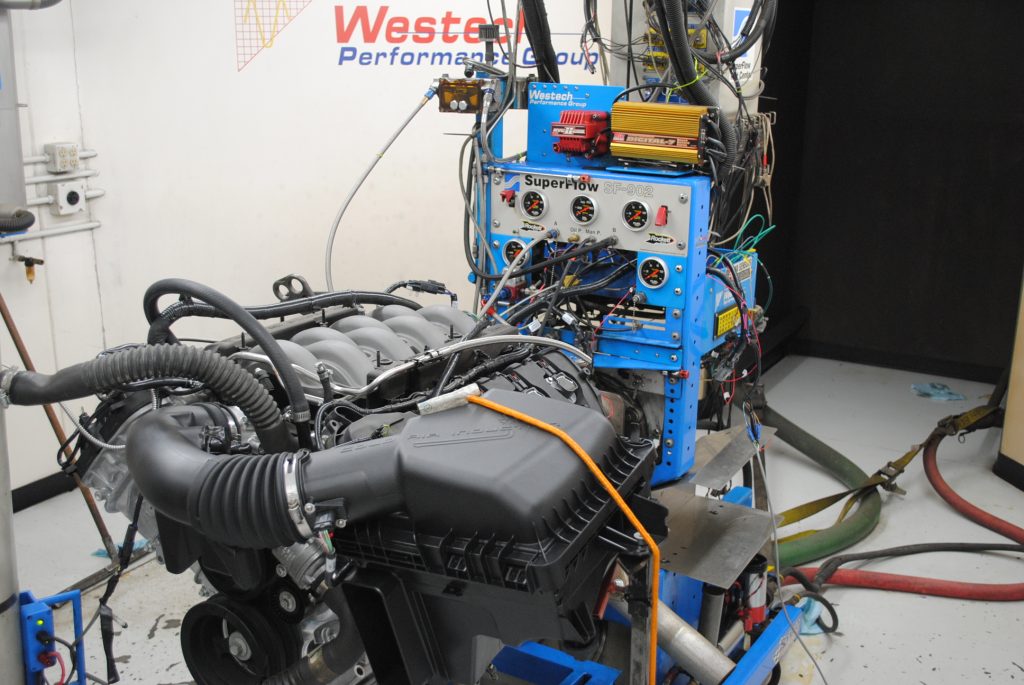

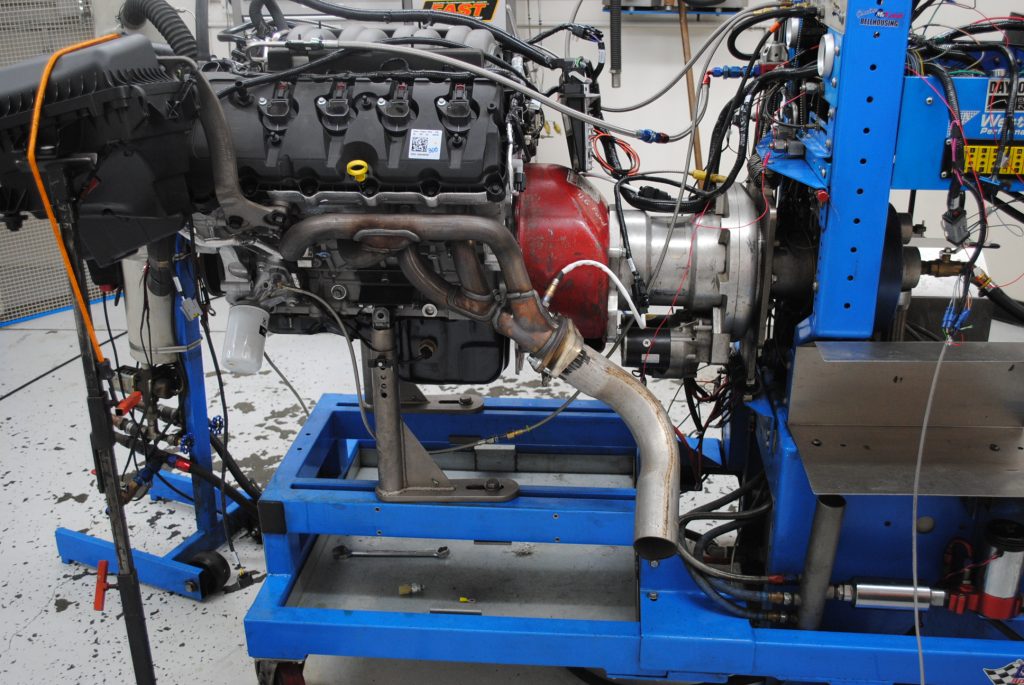

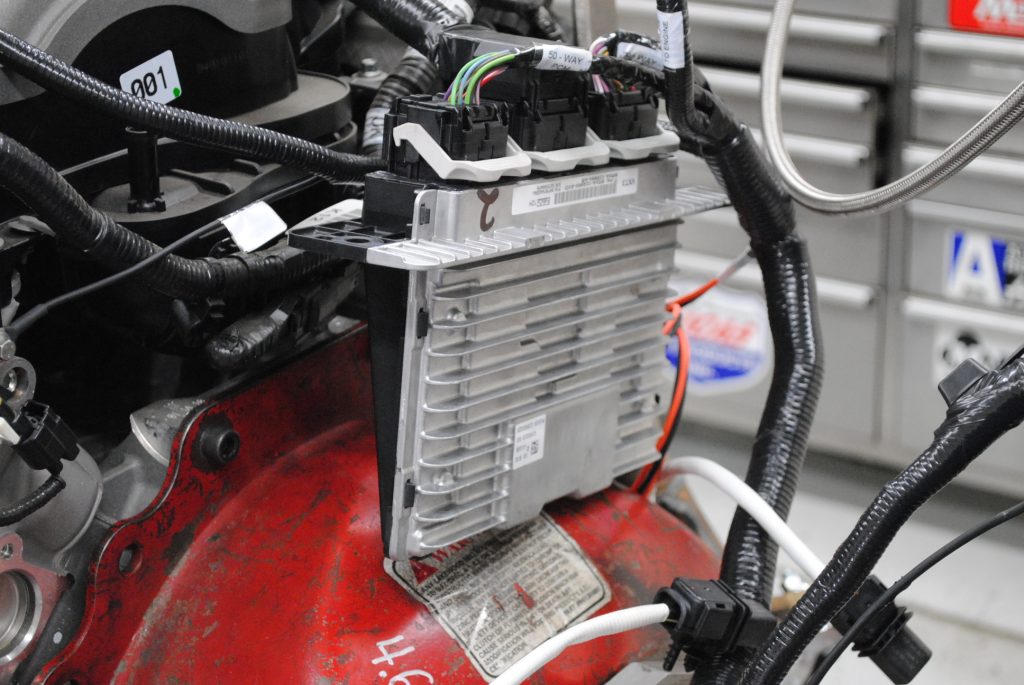

The question for us was did the Coyote respond to aftermarket modifications like the legendary 5.0L and the more recent 4.6L motors did? To find out, we took Ford up on their offer to test a Coyote crate motor, complete with the Ford Performance controls pack to allow installation of the 5.0L up on the dyno.

To get things started, we installed the motor up on the dyno, hooked up the Controls Pack and equipped the motor in typical (dyno) fashion, meaning an electric water pump, factory exhaust manifolds feeding short exhaust extensions and the factory MAF/air intake assembly.

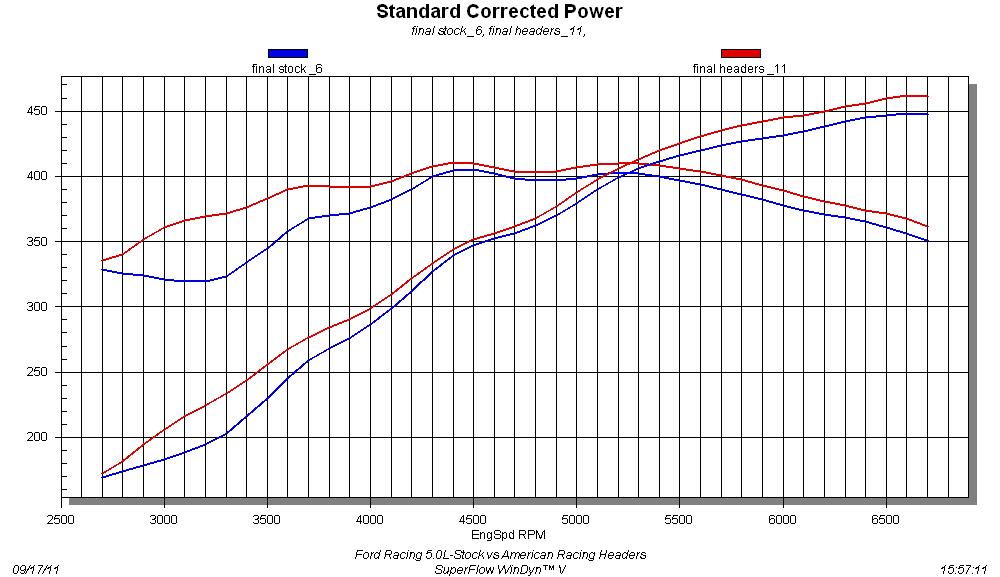

Run in this manner, the Gen. 1 5.0L Coyote motor produced 448 hp at 6,600 rpm and 405 lb.-ft. of torque at 4,500 rpm. This compares to the rated output of 412 hp at 6,500 rpm and 390 lb.-ft. at 4,250 rpm. The difference between our numbers and those generated by Ford can be attributed to the lack of exhaust, accessories and the coolant temperature (165 degrees).

Fans of the original will not doubt remember that the 1987 5.0L was rated at a mere 225 hp and 300 lb.-ft. of torque and that the power curve had long since signed off at 6,500 rpm. By contrast, this modern 5.0L carried power beyond 6,500 and managed to thump out over 375 lb.-ft. of torque from 4,000 rpm to 6,000 rpm. Even down as low as 2,700 rpm, the Coyote produced 325 lb.-ft. of torque. The factory calibration produced 26 degrees of total timing (with less timing lower in the rev range) and a consistent air/fuel curve that hovered safely in the low-mid 12s. After back-up runs illustrated the repeatability of the combination, we were ready to start making changes.

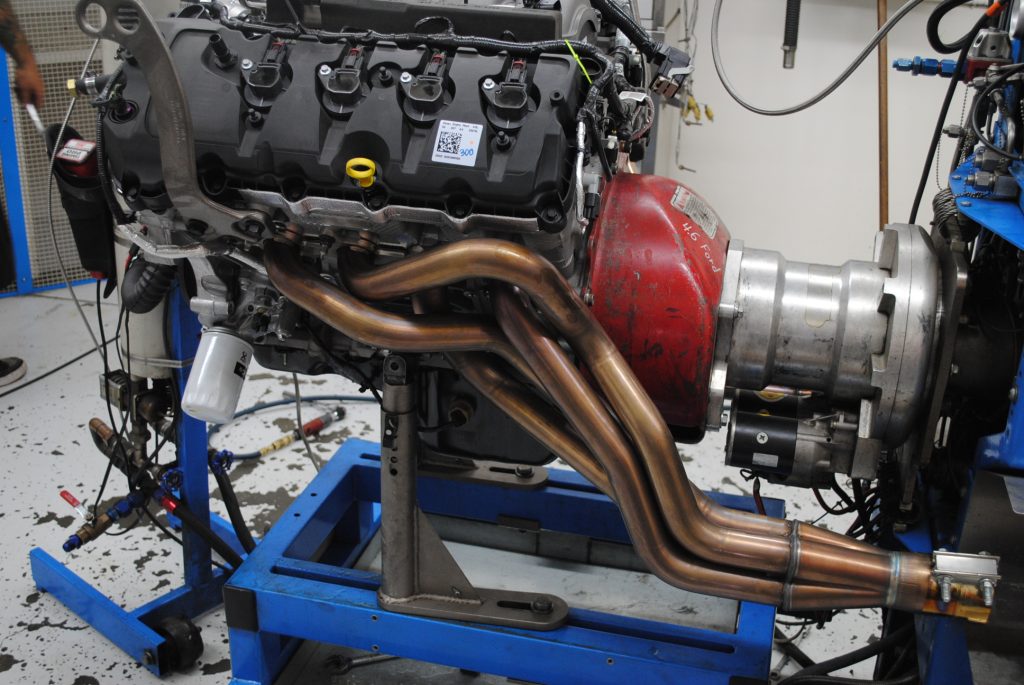

First on the list of mods for our mod motor was a set of long-tube headers. These beauties came from American Racing Headers and featured 304 stainless steel construction, 3/8 inch (thick) flanges and merge collectors with scavenger pipes. The headers were available with either 1-3/4 or 1-7/8 inch primaries and a direct-fit X- or H-pipe. The system can be ordered with or without cats, and was designed obviously for off-road use only. Installation of the headers was straight forward and included an 18 inch collector extension to serve as the exhaust system.

Equipped with the headers, the peak power numbers jumped to 462 hp at 6,600 rpm and 411 lb.-ft. at 4,400 rpm, but the torque output was up by as much as 49 lb.-ft. at 3,200 rpm.

Oddly enough, the installation of the headers altered the air/fuel ratio. Down were the gains were greatest, the air/fuel was now richer (as rich as 11.5:1), while at the top of the rev range the air/fuel was nearly perfect at 13.0:1. We suspect that additional power was available from the header swap had we the ability to further tune the combination, but know that the headers offered significant power gains through the entire rev range.

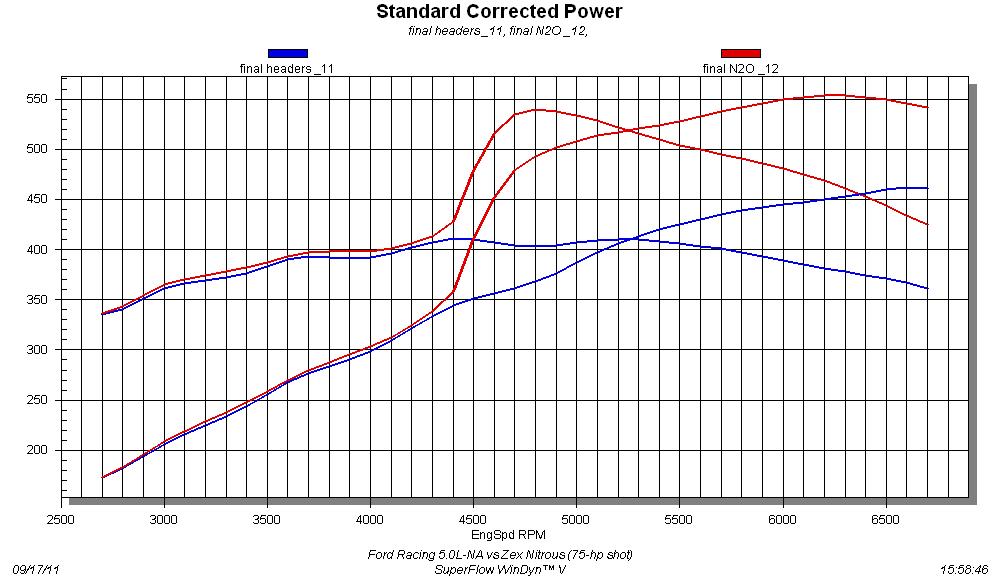

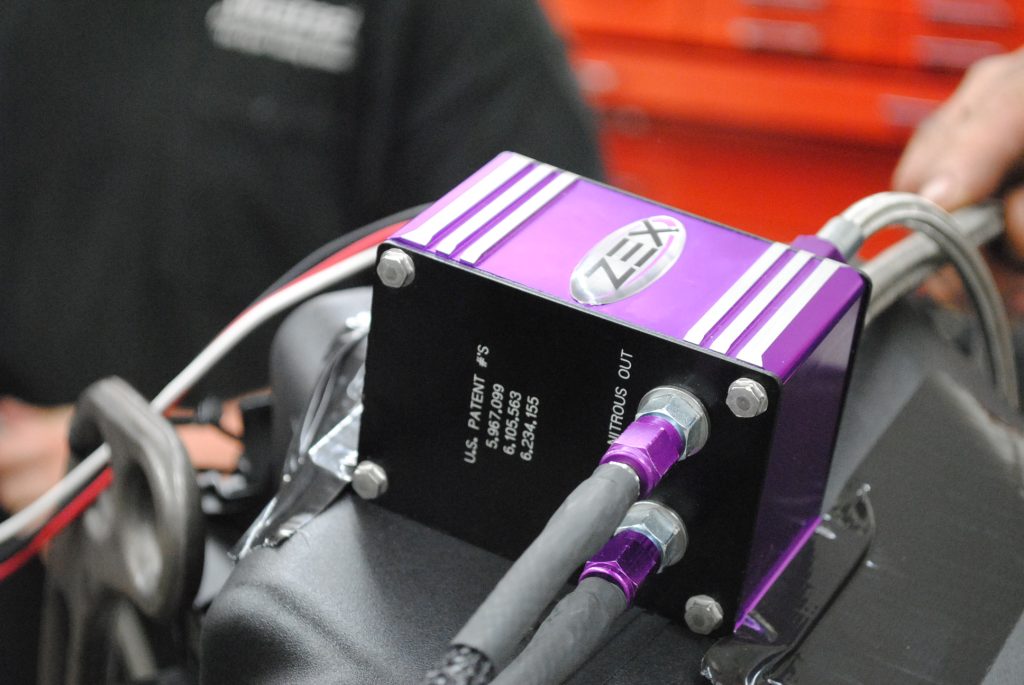

The real power came once we added nitrous to the Coyote. We installed a wet EFI nitrous kit from Zex designed specifically for the 2011 5.0L Mustang. The Zex nitrous kit featured Active Fuel Control that altered the fuel delivery according to the nitrous bottle pressure. The electronic TPS activation switch was designed specifically for the drive-by-wire throttle body and the Zex system was fully adjustable from 75 hp to 175 hp.

Given our limited ability to tune the ECU (we wanted to retard timing by 3 to 4 degrees), we decided to play it safe and start with the minimum power setting of 75 hp. Not wanting to detonate our brand-new Ford Performance crate motor, we opted to add a splash of Rocket Brand race fuel to the mix as well.

Using Westech’s custom bottle heater, we raised the bottle pressure to just over 900 psi and gave the system a whack. The Zex nitrous system performed flawlessly, and the peak power output jumped to 554 hp and 540 lb.-ft. of torque. The air/fuel mixture hovered safely once again near 11.5:1 and the Ford Performance 5.0L never missed a beat.

Later, the same motor would get a Kenne Bell blower, ported heads, cams and a turbo…

Comments