There are so many aspects to internal combustion that it can make your head spin. As enthusiasts, improving horsepower and torque is the name of the game and th.ere are plenty of fancy parts to make that happen. Blowers, turbos, nitrous, cams, cylinder heads, and intake manifolds are the go-to parts for upgrading.

But beyond that, you’ll have to look deeper within the engine to increase power. And the fact remains, all the boost or induction in the world is useless if the air/fuel mixture is leaking past your piston rings. Along with proper valve sealing (at the seats), ring seal is critical to maximizing engine efficiency

Piston rings are necessary, as they, along with the head gaskets and valves, seal the combustion chamber during the all-important combustion and power cycles. Poorly sealing ring gives away power and can create inconsistent results from tuning. In other words, if combustion is leaking past the rings, there’s less force being applied to the pistons to drive the crank. This leakage is termed “blow-by.”

When it comes to rings, there are variations and builders consider bore diameter, ring thicknesses, face shape and material type. The aspects of design change depending on application.

Factory installed OE rings are often tested to last 200,000 miles or more without a rebuild, where Pro Stock rings may only last 10 to 20 runs. Manufacturers offer different designs to suit everything from basic rebuilds to 11,000 horsepower nitro engines. Rings vary in thickness, overall tension, material and even the shape of the ring face can be altered to reduce friction.

“The rings float on the piston and have several jobs, depending on which ring we focus on,” said Cindy Verkooij, director of sales and marketing at CP Carrillo. “The primary job for the compression [top] ring is to seal the compressed gasses during the compression and power strokes and to transfer heat absorbed into the piston back to the cylinder wall and through the cooling system,” she explained.

“The job of the oil ring is to contain most of the oil moving around in the bottom of the engine and return it to the crank case. The second ring scrapes the remaining oil off the cylinder wall, creating the perfect hydroscopic layer for the compression ring to ride on. This, in conjunction with the cross-hatch hone of the cylinder wall, leaves the proper amount of lubrication for the rings to do their job.”

Keith Jones, Director of Technical Sales for Total Seal Piston Rings added, “It is the rings’ job to capture the pressure developed on the combustion stroke and keep it trapped above the rings allowing it to produce as much force on the piston as possible. In doing so, it keeps the byproducts of that cycle from contaminating the oil in the sump. It is also the rings’ job to seal [each cylinder] on the intake stroke, in turn, pulling as much air and fuel into cylinder as possible. This is very important when working on a normally aspirated application. And if that isn’t asking enough, they also have the keep the oil below the rings and out of the combustion chamber.”

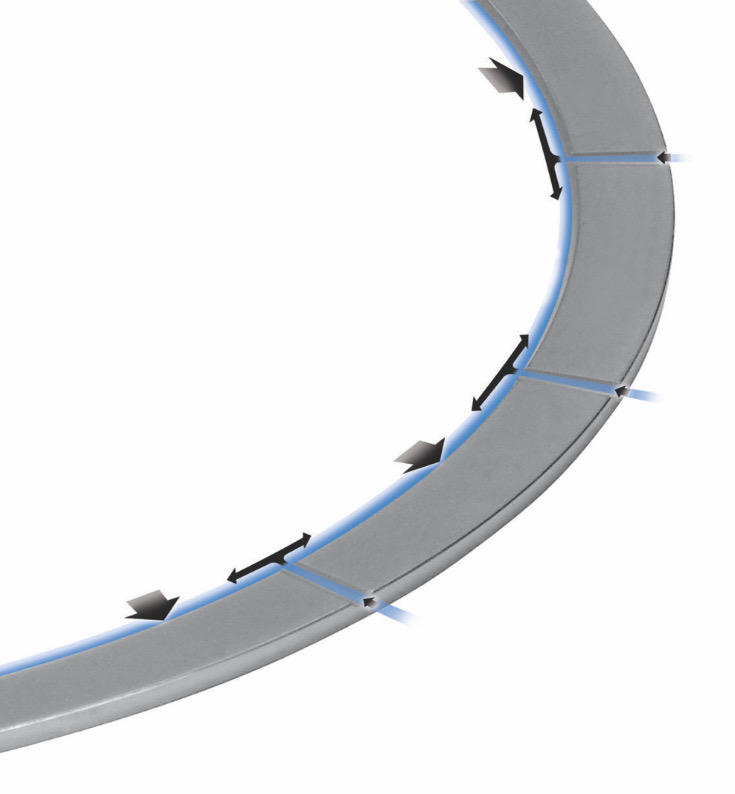

“The rings do contact the cylinder walls, but only slightly if everything is done correctly,” said Jones of Total Seal. “Think of the rings like a water ski going across a body of water. When the ski is moving slowly it will be sunken down into the water and not ‘up on plane,’ but as it speeds up and begins to move faster it rises out of the water. A piston ring does the same thing as it moves through the stroke. Remember, at exact TDC and BDC the rings stop moving, if only for a microsecond, but from those points on as they move towards mid-stroke they are accelerating and then decelerating. When near BDC and TDC, the rings are running in boundary contact and as they moves away from BDC and TDC they are running in a mixed film condition,” Jones added.

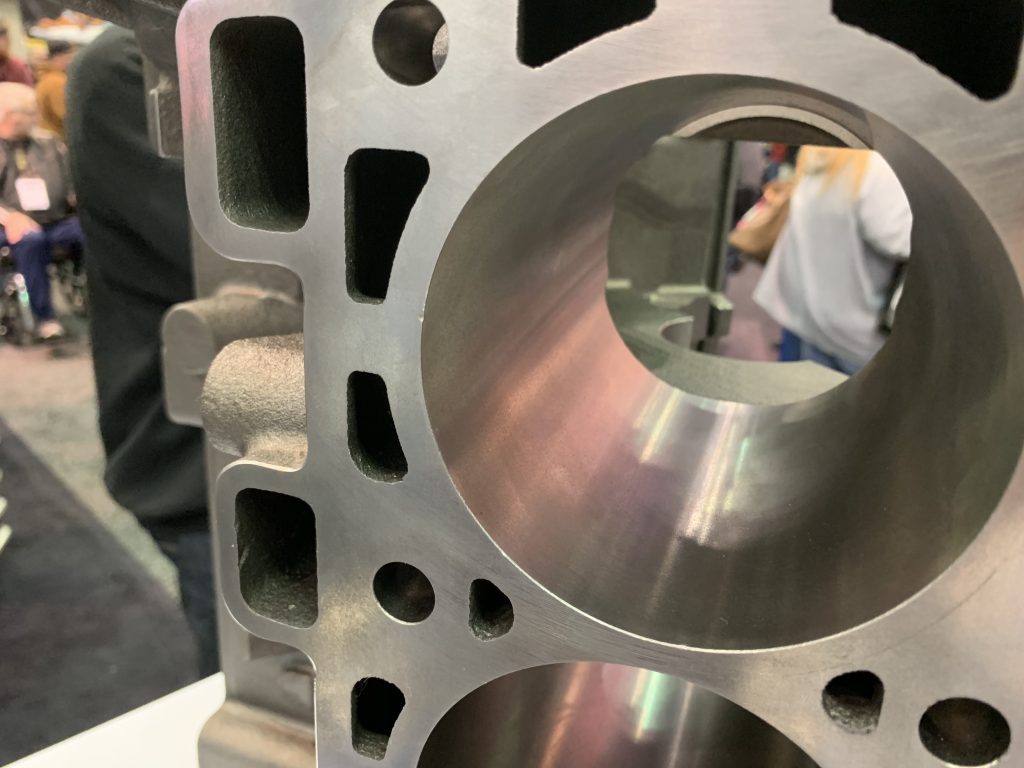

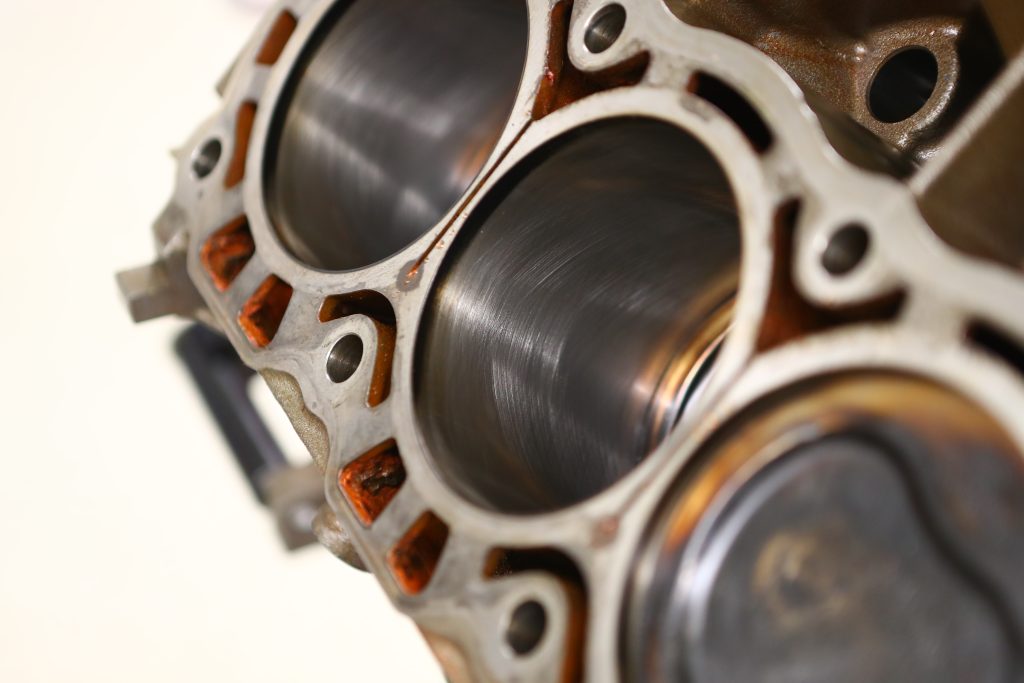

Of course, your rings will work best with the desired cross-hatch that’s created as the honing stones are moved up and down the cylinders during machining. This is critical to proper oil retention and combustion sealing.

“This as important as any other part of the engine package. The best rings in the world cannot fix a bad cylinder,” said Jones. “Getting proper surface finish and bore geometry should be on the top of list with any other operations being performed.” The cross-hatch angle is also important. Too steep and oil bleeds off too fast, too horizontal and the oil film doesn’t get recycled enough.

Street vs. Strip

Today, street(able) engines can make upwards of 2,000 to 4,000 horsepower, but they run longer than drag-race only engines. That’s why street performance rings are often taller in axial height and wider in radial thickness. Some drag engines use dry sump oiling and vacuum pumps that can tolerate thinner/lighter tension rings to reduce drag.

Jones added, “Sure they do differ in sizes, tensions, materials, etc. They are two very different environments. Street is always a compromise, we want to keep the drag down and the engine dry, but the street environment must do many thing ‘race cars’ don’t have to do. For instance, cruise down the freeway, sit at stoplights, there’s engine braking going down a mountain range, etc. So, when we have a dedicated environment, say like Pro Stock or Comp Eliminator, we know we have a pretty good idea what the operating condition is going to be like, and we can tailor the ring pack. Example, we may run a 0.6, 0.6, 2.0 ring pack with only a 4-5 lb. oil ring with very light tension in a comp application and get great service life, but this won’t work in a street application.”

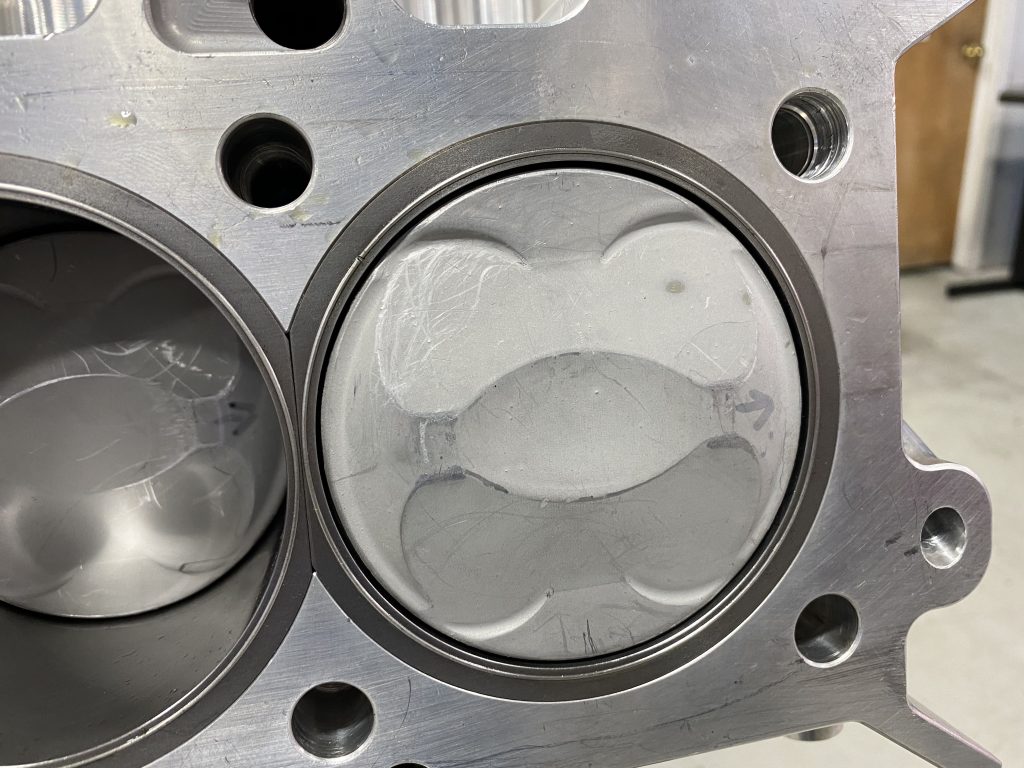

Gas Porting

The terms refers to holes machined in the pistons to allow combustion gasses to more easily get behind the rings to increase sealing. Gas porting can also be done to the rings with the same result.

“The rings do not really change in material or coating,” stated Jones. “Gas porting is used to get the required gas pressure behind the ring to push them out towards the cylinder wall. The static pressure of the ring can only do so much. If the ring has enough vertical clearance between it and the ring land it will get the needed gas pressure. But the tighter we can run the ring to groove clearance the better the ring seal will be, but only to the point that we cannot ‘gas load’ the ring properly. When that happens the ring blows off the wall and it all goes out the window. So how do we tighten up that clearance and get the necessary pressure behind the ring? You guessed it, gas porting. This allows the vertical clearance to be very tight and still get the pressure behind the ring—this why we introduced our Gas Ported top ring sets. This allows the end user that has not purchased pistons with ports to get all the benefits of having same. We have the results of many dyno tests showing improvements. The amazing part is, I have never seen an application lose power or have increased blow-by using same. And if it is a power adder or nitrous-assisted engine, I would always run a gas ported combination whether it be in the ring, the piston or both.”

Ring Material, Coatings & Face Shape

“In terms of material, most common are various grades of iron ranging from cast to ductile iron,” said Jones of Total Seal. “And steels ranging from carbon, stainless and M2 tool steel. Of those, the ductile iron and stainless steel are the most popular here at Total Seal. We offer a wide range of coatings from common Molybdenum to Diamond like carbon and beyond. And we have some I can’t discuss in public. As far as what they do, it’s three-fold. They help to reduce friction, increase wearability and help to improve ring seal.

“Top rings are typically barrel faced to aid in keeping the ring sealed on the cylinder wall as the piston ‘rocks over’ during TDC and BDC. Second rings are typically taper-faced to aid in scraping oil back down to the sump. Both of these profiles are vast improvement of simple flat-faced rings. There are other more exotic profiles like offset barrel etc., but these are typically application-specific.”

Cindy Verkooij, director of sales and marketing at Carrillo stated, “In today’s drag racing world, steel compression rings are becoming more common, and seal better for long duration/endurance applications. Although plasma and ductile Moly face rings are still available, it really depends on the application. Different processes are used on some of our rings, such as Gas Nitride and PVD. Both Gas Nitride and PVD offer a much higher level of resistance to the higher heat that today’s turbo, blower and nitrous engines are making.

“While top rings are predominantly barrel faced, the second ring design differs because its job is primarily to scrape oil away from the top ring and back down to the crankcase. To accomplish this, an angle is manufactured onto the face of the ring. There are two main popular styles: napier and non-napier. The design of a napier ring has a “taper hook groove” (THG) added to the underside of the face of the ring, which acts like a “squeegee” to the oil on the cylinder wall. With this improved oil control via the second ring, it allows for lighter tension oil rings and lighter overall ring packages to be used.”

“A ring’s axial and radial primarily determine the ring’s tension,” said Verkooij. “Historically street cars would have higher tension, while lower tension was reserved for race cars and dry-sump oil systems. But in the last decades ring technology has improved, and piston ring grooves have gotten flatter. This allows many low-tension setups to be more common for racing and street applications. The tension of an oil ring has a direct relation to oil control. The higher tension, the more it can control oil and do its job, but the more force and drag it puts on the cylinder. Hence low tension is often requested for the lower-drag benefits it offers.”

Keith Jones of Total Seal added, “high-tension vs. low-tension is very application dependent. Lower friction is always best, but trust me a 5.000 bore Pro Mod is not running low tension parts. We always want the tension as low as allowable based on the given application. Oil viscosity can affect rings especially during the initial seating period. We generally like to see the lightest oil you can get away with safely. Lighter oils are easier to return to the sump and flow more easily, but they must be able to provide the proper lubrication to all the parts, not just the rings.”

Total Seal also offers gapless rings and we wondered if there were specific applications that would benefit most. “We recommend gapless rings whenever the budget allows,” said Jones. There are always price point considerations and personal preferences. They draw harder on the intake stroke in turn filing the cylinder better and will build more cylinder pressure. This can make the engine think it has a bit more compression. So if you have a class that requires say 9:1 compression these may help. They are also very helpful in keeping excess fuel out of the pan. And they are handy in the ever-popular nitrous classes. These engines must be machined with clearance for the worst-case scenario. But when not being run to that extreme, they may experience excess blow by due to the large end gaps required when running the nitrous. Going gapless eliminates this issue.”

Comments