I have a big block Chevy engine in my 1955 Chevy with an 850 cfm Holley carburetor and a big Holley fuel pump and return style regulator. I just changed the fuel pump and reset my fuel pressure. What I did was just turn the switch on that runs the pump with the engine off and set the fuel pressure at six psi.

Then just the other day I took the car to a show and later started the engine with the hood open for a friend to hear it run. I have a small mechanical fuel pressure gauge right near the carburetor and I was surprised when the gauge showed something like only two or three psi. The car runs fine but I’m not sure why the fuel pressure dropped. Maybe the gauge is bad? Thanks.

G.K.

We’ve run into this situation back in the days of dead-headed fuel pumps and carburetors before return fuel systems became popular. The simple explanation is that with the engine not running, there is no fuel flow into the float bowls. When the pump turned on, it filled the float bowl which quickly closed the needle and seat.

When you set the fuel pressure, this was with no fuel flowing into the bowls, you adjusted the pressure with the regulator at six psi. Now when you start the engine, a small amount of fuel is being consumed from both the primary and secondary fuel bowls. Even this very small amount of fuel flow affects the adjustment so the pressure now displayed on the fuel pressure gauge is lower.

My guess is that the gauge is reading accurately or close to accurate.

What makes this seem more dramatic is that those small fuel pressure gauges are not always accurate. My personal feeling (although I have never tested this) is that these little gauges are probably accurate only within +/- one psi depending upon the quality of the gauge. So if we’re dealing with a six psi reading, it could actually be anywhere between five and seven psi.

Summit Racing sells a small diameter liquid-filled fuel pressure gauge that can be mounted near the carburetor. Liquid filled gauges tend to be more stable because the liquid dampens the gauge movement. However, these gauges are affected by under-hood temperature. This means that the gauge will read differently when exposed to heat compared to ambient temperature so keep that in mind. Some liquid filled gauges offer a small rubber plug that can be removed to equalize the pressure with ambient air pressure to allow the gauge to be more accurate when heated.

How Much Fuel Pressure Does a Carburetor Need?

More importantly, your engine probably ran fine because you still have adequate fuel flow into the carburetor even with a very low fuel pressure. It’s important to note that more fuel pressure is not really a good idea. Many enthusiasts think that if four psi is good, then seven psi is better. The truth is that four to 4.5 psi is more than sufficient to supply a hungry 850 cfm Holley carb feeding even 700 hp, if everything else in the fuel delivery system is properly designed. Higher fuel pressure tends to overcome the needle and seat, which can cause problems with a slightly higher float level, that then causes the boosters to drip fuel into the engine.

How to Set Your Engine’s Fuel Pressure

The proper procedure for setting fuel pressure is to always adjust the fuel pressure with the engine running at idle. With the fuel pressure set correctly with the engine running, it would be wise to also recheck your float level. It’s possible that the additional pressure may affect float level.

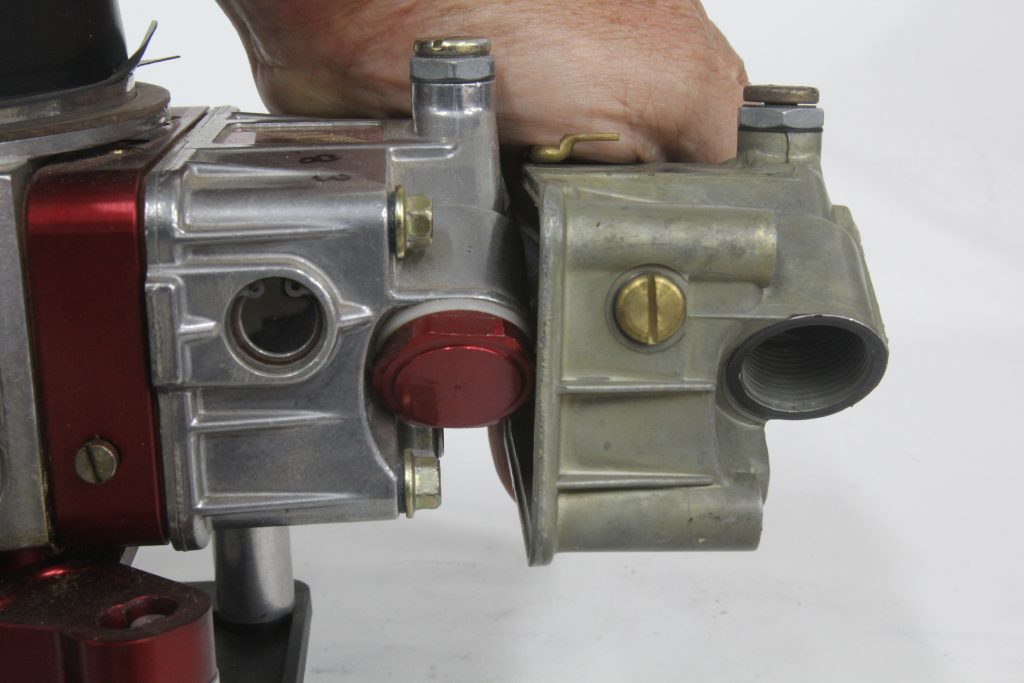

Older Holleys with the brass, screw-in sight plug set the fuel level to just under the bottom of the sight plug hole. With newer Holleys that use a large glass sight, the proper level is in the middle of the window—not the bottom.

I recently helped a friend tune his Holley after he complained that the engine hesitated on acceleration. It turned out he set the float level to the bottom of the larger sight glass and this caused a major off-idle hesitation. We raised the float level to just below the middle of the sight glass and this eliminated the hesitation.

It’s also worth noting that minor tuning changes can be accomplished by slight adjustments to the float level. A higher float level will cause the carb to run richer while lower will edge toward a leaner overall mixture. One way to judge this is to use a single flat side on the six-sided adjustment nut. One flat is a measurable change in float level.

Comments