The Chevrolet Corvette C5 Z06 was produced between 2001 and 2004 and has been a formidable weapon at autocross and road racing since day one. As depreciation sets in, these cars have become more attractive to racers looking for inexpensive speed.

For several reasons:

- The C5 Z06 has a ridged chassis, yet is relatively light at 3,060 pounds with a quarter-tank of gas.

- Good aerodynamics. Low center of gravity. Good suspension geometry. Analog driving experience.

- Factory 18 x 10.5 wheels accommodate 315 rubber and can be run on all four corners.

- Great aftermarket support. Engine, chassis, brakes — anything you can imagine.

- Many spare parts. They shared many parts with standard Corvettes.

- One car does it all: SCCA, Optima Ultimate Street Car, NASA, land speed, drag racing — you name it, it’s won it.

- Wreck one? Just bolt the leftover parts on another roller.

- LS baby! The 2002-04 cars had the sturdy 405-horsepower LS6 with tons of potential.

Grassroots Motorsports magazine is known for great car builds in a logical progression. They build in the sequence an average enthusiast would.

No pie-in-the sky parts on day one.

Just good, solid bang-for-your buck recommendations and back-to-back results. It’s all about fixing what’s broken first, and the best speed per dollar from there.

GRM’s C5Z build is no different.

J.G. Pasterjak bought his 93,000-mile 2004 commemorative edition in July 2017 for under $18,000. The buildup sequence can be found here.

To summarize, the buildup sequence on a typical track-day C5Z is:

1. Replacing the worn suspension bits with new dampers or coilovers, bushings, and a bigger front sway bar.

2. Wheels and Tires. With 200 treadwear tire events like Optima and CAM-S events being so popular, there are several good choices. You can buy a spare set of 18 x 10.5 rears to mount up front and run 315 squared.

…

3. Brakes. Good pads can go a long way with autocross. For track days, 14-inch six-piston brakes in front and C6 Z51 rear brakes will get the job done.

…

4. Clutch. The stocker starts hanging up around 400 whp. While the torque tube is out, go with solid driveshaft couplers. A 45-lb. twin disc clutch and flywheel are recommended for better pedal effort, shifting, and slippage.

…

5. Replace the parts a driver interfaces with. Most important are the seats, steering wheel, harness bar, harness and shifter.

…

By now, most C5Zs have at least headers, tune, thermostat, cold-air intake, and make an easy 400 horsepower at the wheels. If the bottom end of the engine is in good shape, one option is doing a heads / cam / intake swap. This nets 450 horsepower at the wheels pretty easily. Here’s the LS6 engine upgrade guide to walk you through the steps.

Pasterjak wanted to make a bit more power and torque.

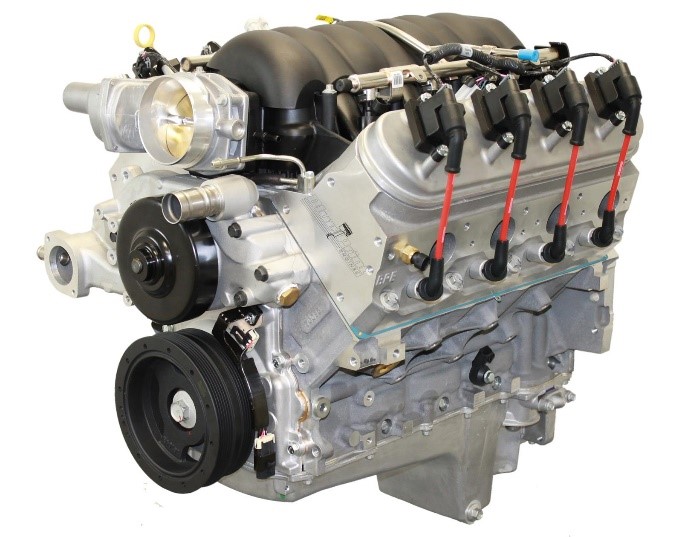

After consulting with Summit Racing, Pasterjak decided on a 530-hp BluePrint Engines Pro series LS3 crate engine.

At first glance it might seem more expensive than a typical H/C/I swap — but the engine is brand new and has a warranty. Selling the original 346 c.i.d. LS6 for $3,500 made the deal a no-brainer.

Similar to the Chevrolet 525-hp 376 c.i.d. LS3 crate engine, the BluePrint engine uses a more refined camshaft for more power and better driveability.

Right out of the box, this translates to about 465 hp and 435 ft.-lbs. to the wheels.

As the car is further developed, the LS3 can be further upgraded with a 416 stroker kit and Trickflow 255 cylinder heads. With a slightly more aggressive cam, it can make an easy 535 hp and 520 ft.-lbs. to the wheels — yet remain very driveable and durable.

Here’s a video of Pasterjak and crew uncrating the engine after speaking with Steve Kester from Summit Racing’s retail store in McDonough, GA.

The engine is a near drop in, but a couple changes are needed to fit the C5Z.

The original LS6’s accessory drive and water pump will bolt onto the LS3, as will the batwing oil pan. It will require a Lingenfelter TRG-002 conversion box to mate the 58x reluctor’s signal to the factory ECU.

NOTE: A LS2 drive-by-wire throttle body is required to communicate with the factory ECU as the crate engine’s LS3 throttle body is incompatible.

Another option is retaining the LS3 throttle body and running a highly configurable ECU like the Holley Terminator X.

For Pasterjak’s full-race configuration, this makes more sense.

It’s plug and play with the Holley dash, shift light, and other modules. It also has extra inputs and output channels as the car advances. The GM throttle pedal (NAL-10379038) is required as well.

We’ll keep you posted as the Grassroots Motorsports C5Z project progresses!

very nice and useful.

Not a car enthusiast but that is some car you got there! The machines inside look flawlessly shiny.