(Image/Summit Racing)

Pushrods take a lot of flak.

“OHC” this, and “primitive” that.

Pushrods don’t live an easy life either. They get covered up, never to see the light of day, and bumped around by cam lobes from one side and smacked back by rockers and springs on the other. It would seem like a thankless job, but a good engine builder appreciates them plenty.

The Consequences of Pushrod Deflection

(Image/Grumpy’s Performance Garage)

When a pushrod deflects, several bad things happen, including:

- Loss of valve lift.

- Loss of valvetrain stability. The valve is no longer opening and closing at the rate the lobe designer predicts.

- Slack in the system means the components start banging against each other and breaking.

- When valves are bouncing off the seats, they’re not sealing and power is lost.

And remember, it’s not just 500, 800 or 1,300 pounds of open spring pressure that’s causing the deflection.

Inertial loads from heavy valves, springs, retainers, rockers, and the lifter can create more than 5,000 lbs. of force. Think about an entire SUV balancing on top of a seven-inch tube thinner than your pinky. That pushrod is moving around more than a pogo stick in a hula contest.

So how strong does a pushrod need to be? The short answer is: Use the biggest/thickest one that fits.

What about weight? The pushrod moves a short distance compared to the valve, spring, and retainer due to rocker ratio. The weight is much less in comparison too. Because of this, the added strength more than offsets the increase in mass.

Summit Racing HDR Premium Pushrods

Enter the Summit Racing HDR premium seamless chromoly thick-wall pushrods.

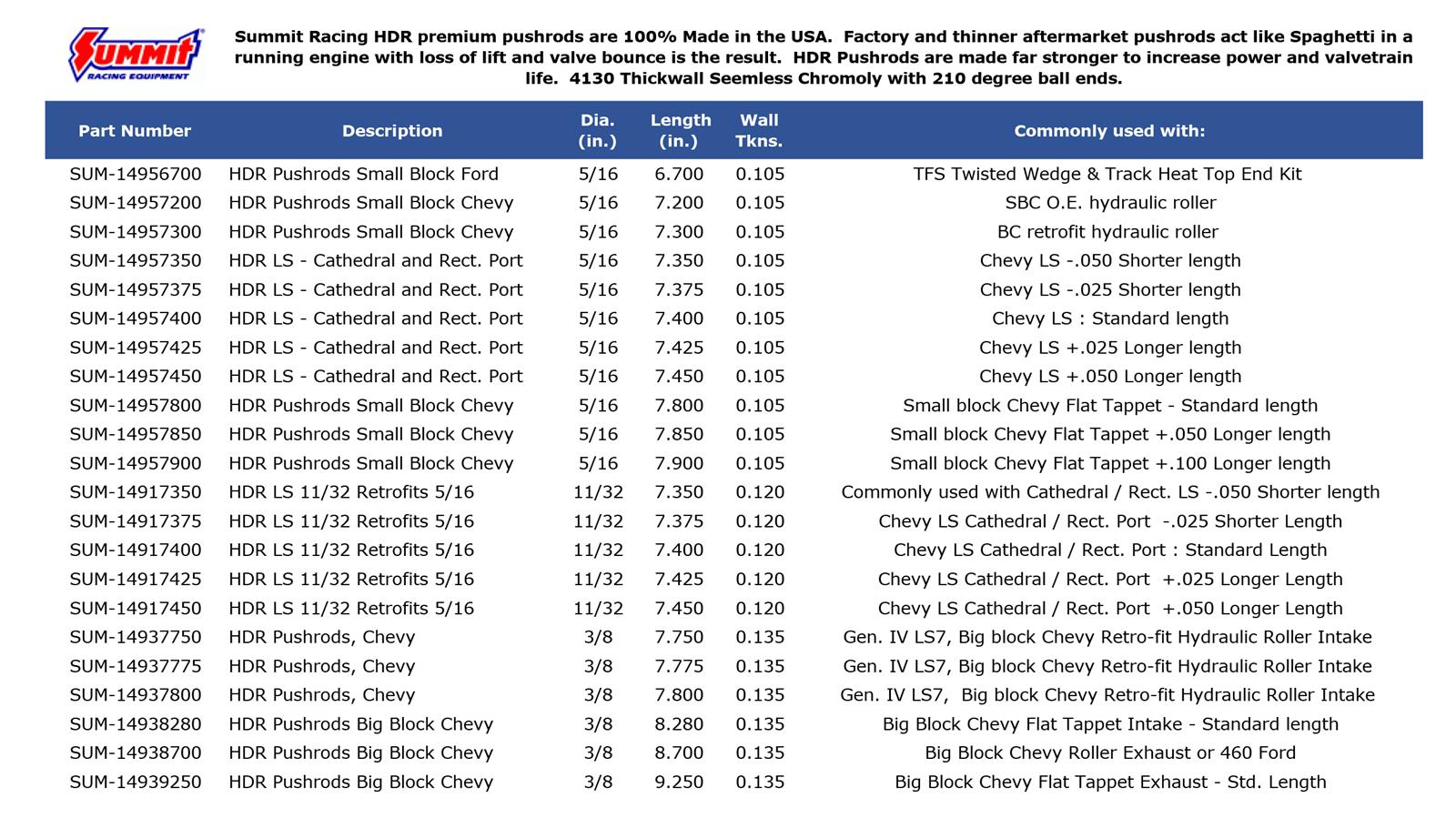

These pushrods are 100-percent made in the USA, and come standard with 210-degree ball ends for more rocker clearance at max lift. They are available in common LS, SB Chevy, BB Chevy, and SB Ford Windsor lengths.

How strong are they?

Summit Racing used FEA (Finite Element Analysis) in the initial testing. They could have compared them to thin-wall welded-ball factory pushrods, but who in their right might would use those? The following results are based on improvements over typical .080-wall aftermarket pushrods.

- The 5/16 x .105 wall pushrods have 25-percent less deflection.

- The Pro LS 11/32 x .120 are .030 larger in diameter, yet fit in place of the factory 5/16. They’re also available in .025 increments to fine tune hydraulic lifter preload. They have 28-percent less deflection than a typical 5/16 .080 wall chromoly pushrod.

- The 3/8 x .135 pushrods commonly used in big blocks has 20-percent less deflection.

So the bottom line? Summit HDR pushrods are some of the best horsepower-per-dollar components available for your engine.

The Summit Brand of high performance and racing components are steadily evolving into what I would consider to be TOP QUALITY and PREMIUM in every sense of the words. I need a great set of 3/8” pushrods and from all indications, Summit has exactly what I need … I hope.

Maybe this is only a partial list of their offerings but as typically found in the aftermarket parts business, virtually every application is well covered, IF YOU HAPPEN TO BE BUILDING ANOTHER CHEVROLET ENGINE.

I fully realize the supply and demand aspect because the majority are building what they consider to be the ONLY engine worthy of their resources. Fords get very little recognition in our great performance industry. That is, until one starts consistently winning races in the world of GM biased Motorsports. That’s when something must be done immediately to “fix” the situation and the sanctioning bodies quietly go about the business of juggling the rule book to factor the offending Ford (CLEVELAND) right out of the winners circle…AGAIN. But that’s a messy can of worms to be opened at the appropriate time.

I must give credit where it’s due because Chevys have good potential and there’s no denying their majority status. I could also be like everyone else and build what’s already been done millions of times.

Yes indeed I am a Ford minority and my engine of choice is the 351 Cleveland based alternative. Surely you remember it from the YEARS it dominated Pro Stock in various 330 cubic inch combinations and the NASCAR versions frequently in the record books and winners circle . Unfortunately it was finally defeated by the power of the pen and subsequent rule changes. Disgruntled Chevy and Chrysler die hards quit buying race tickets along with the sponsors beer and tampons when a lowly Small Block Ford takes the checkered flag almost every weekend. But big money, politics and some Pro butt kissing brought much joy back to the masses again and lined all the right pockets with gold. Problem solved…for the chosen ones.

But enough ancient history. Suddenly it’s 2019 and im seeing some choice Summit Brand parts. The parts list in this article has them for all varieties of Chevy and in the description it kinda hints that the part might even work with a Ford. NICE !

For those that have been so involved with their modern LS engines, which for some strange reason still uses antique pushrod technology, you really need to know what the competition is doing now. This way you can have all of your track equipment loaded up and ready to beat the rush by leaving early in the elimination rounds.

Fords superior small block Cleveland will be appearing more often at tracks everywhere now thanks to a few dedicated professionals that are reproducing exact duplicates (with modern upgrades) right down to the period correct casting numbers and date codes. An engine is only as good as it’s weakest link and when engine builders got serious about tweaking 351C, 4-V quench heads to do what the Ford Engineering Team originally had in mind from the beginning, they found head flow and velocity that put ALL small block heads, regardless of the origins, to shame and very few big block heads were in the same league.

When installed on the only block available at the time, meaning a factory production block prepared for competition, the results were awesome while on the way to disaster. Canted valve Cleveland heads were just starting to come on strong when SBC heads were suffocating from their own design. It doesn’t take very many 10,000+ rpm blasts to expose any weaknesses in the block. While cast iron production blocks are fine for most street/strip builds taking care of business by ~7500 rpm’s, more serious builds will see extended rpm’s to put good heads and solid rollers in their sweet spot.

I said all of that other stuff to get to the good stuff. Good Cleveland block cores are no longer of concern due to their dwindling supply. Timothy Meyer, TMeyerinc.com has devoted the last 10 years perfecting his new series of TRACK BOSS Blocks featuring full Cleveland architecture that will work with either Stock production Cleveland parts and accessories OR the latest and most radical aftermarket parts currently available. Externally it looks identical to a common 351 Cleveland block so if you seek originality for your restoration, the Track Boss is waiting for you. But Stock rebuilds are not why this block was created. It employs a modern main bearing priority oiling system that routes a full supply of oil directly to the main bearings before oil is distributed to the upper regions of the engine and valve train. The original Ford production blocks didn’t have this essential feature because the Ford budget bean counters found they could save a few beans on every block produced by using one less oil gallery that would have fed essential oil to the main bearings before the upper valve train components first and then down to the mains. Like WTF guys. One less block machining step surely saved FOMOCO from financial disaster…or certainly NOT !!! For 98% of all street/strip performance rebuilds, the production oiling system works great. But the remaining 2% are utilizing the full Cleveland heads ultimate advantage and the balls to the wall with the powerful( for a totally stock small block Windsor) “M” code 351W. I don’t want to disturb anybody’s Windsor euphoria so I will be very considerate of wounding a Windsor owners inner child. Let’s just say it WASN’T a Cleveland

Oh my, look at the clock on the wall. My thoughts in a paragraph or two turned into something else and strange. I do want to discuss all the amazing new Cleveland parts that became a reality over the past year. If you wear a bow tie with your paisley t-shirt then you can always find something else to read. Summit rules the performance aftermarket and yes I really do need your best pushrods that are hardened for guide plates, 3/8” diameter with as much wall as reasonably possible. The length for stock is 8.4” but I seriously doubt that’s still applicable with my solid roller setup and the deck surfaces shaved slightly for squaring and surface clean up. Still to come…Cleveland blocks in premium aluminum alloy OR Compacted Graphite Iron ( CGI ). Sourced entirely from American metal stock, poured at American foundries and given the full CNC preparation by an American Master Machinist in his modern American Facility. Oh by the way…His Blocks have already been approved for Class Competition by the NHRA ! Time to turn up the heat cause CLEVELANDS ARE BACK….BIG TIME. Next stop, the Winners Circle, no doubt .

That, sir, is one heck of a comment!

Oh heck yeah,been a FORD man all my life,do the best I can with a Windsor,will be checking soon on CLEVELAND!!!

Hard to find Parts for ford 429-460 ? Roller cam, intakes, headers?

Do you know roughly the amount of flex I should expect from your 5/16 7.8 0.105 pushrods at 7500 rpm and 640 lb/in springs with 0.77 total lift with 1.6 ratio crower shaft stainless rockers?