When building a LS engine, you have a lot of questions and things to decide like:

- Where will my bores clean up?

- How many cubic inches am I going for?

- What kind of compression ratio am I targeting?

- What parts are strong enough for boost or nitrous down the line?

Enter Summit Racing’s new Pro LS forged pistons for Gen. 3 and 4 LS car and Vortec truck engines. They’re 100% made in the USA and precision machined from forged 2618 aluminum.

Summit Racing makes your life simple with a full line of pistons that fit popular strokes, rod lengths, and bore sizes. From there, the compression ratios have a nice spread starting in the mid-9:1 range for boost and up to 11.5:1 for naturally aspirated or nitrous motors.

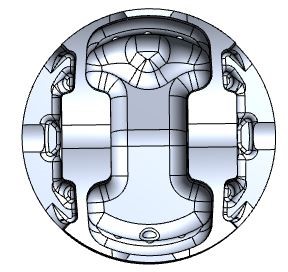

Not only do they accommodate larger valve diameters, the 6.0L and larger pistons receive combination Cathedral/Rectangle port valve reliefs to maximize piston-to-valve clearance. This allows you to swap to a higher flowing cylinder head later down the line if you want.

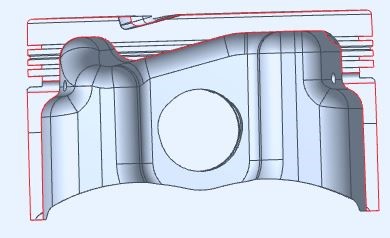

The heart of a tough piston is the forging. With the Pro LS pistons, 2618 alloy forged aluminum was chosen for its ductility and crack resistance. Careful attention to the material thickness in the crown increases strength without a weight penalty. One area that wasn’t thinned up were the corner radii. These were left large to increase strength in critical areas.

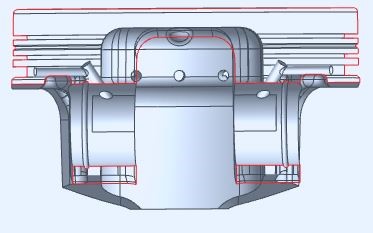

The link between the piston and connecting rod is the wrist pin. Summit Pro LS pistons are designed around a 2.250-inch pin length. There are several reasons for this.

- Pro LS pistons don’t need to be notched to clear the reluctor ring in stroker applications. Forgings have a grain and cutting across it creates a weak spot that can allow a crack to start.

- To maximize pin and pin bore life, the pin boss span is moved inboard and captures the factory connecting rod small-end perfectly. This reduces pin flex by putting it into shear rather than bending.

- The forced pin oilers lube the pins with every down-stroke. The design maximizes bearing area for reduced pin bore wear.

- Lighter pistons and pins are the result. This take tons of stress off the rods, crank, and block. All can be lighter. The result is less horsepower required to spin the rotating assembly up.

The number one cause of piston failure is ring land breakage. When it’s not from detonation, tight ring end-gaps are normally to blame. When rings butt from excessive heat, they go wavy like a potato chip. The stress breaks the top or second land. What does Summit do about this?

To maximize ring land thickness, ultra-modern ring packs are used. Anything you subtract from ring land thickness can be added to the ring lands. Top ring land thickness on Summit Pro LS pistons are a minimum of .275-inch and often .300. The second land is a beefy .165-inch thick.

How do they hold up on the street and how quiet are the Pro LS pistons compared to the forged pistons in a factory LS9 or LT4?

The piston skirt profile is highly optimized with minimal cam and taper. They run at tight clearance with minimal piston rock. They also have a premium skirt coating that allows them to be fit tighter. Another interesting design feature is the width of the skirt panels and the angle and scallop of the vertical strut walls leading to the pin towers.

The benefits are:

- Increased piston stability

- Minimal wear

- Reduced weight

- Engineered-in flexibility that won’t stress the cylinder walls.

- A quieter piston

- Increased ring seal for more power.

What’s the secret to this?

When a piston is up to temperature, it’s dealing with the high combustion heat at the top and relatively cool oil temperature at the bottom. The rings are bleeding off heat into the cylinder wall and water jacket to keep the piston from melting. To compensate for thermal expansion, the piston must have taper from top to bottom and cam (oval shape) to compensate for the piston’s structure. Pro LS pistons have perfected the cam and taper required to ride perfectly in the bore.

What about the stroker pistons?

Strokers had a partially-undeserved reputation for wearing out piston skirts and oiling due to lack of support for the piston at BDC. Some identify the piston hanging out of the bore at BDC as the culprit. The real cause is some of the cheaper pistons don’t have the correct taper for stroker applications. The taper starts below the bottom of the cylinder at BDC. This creates a sharp intersection and wears out the piston skirt every time it moves up the bore.

Total piston taper is important, but where it starts above the cylinder at BDC is even more important. Pro LS piston skirt taper starts higher on the piston than others. This adds stability at BDC, and the piston guides itself up normally. Where this taper is introduced below the oil ring groove is called the break-point.

For those of us that hate math, here’s a simple diagram that shows a Pro LS 6.0L piston designed for a 4.000in. stroker crank. It’s at bdc with a common iron-block cylinder length of 5.430 in.

The 6.0L stroker pistons have a 1.2, 1.2, 3mm ring pack and 1.110 compression height. The tapers break point start at .525-inch below the oil ring groove.

The lands are maximized with a .300 top, .165 second, and .075 third land. When we add the ring groove thicknesses in, the result is what called total ring stack. In this case it’s .785-inch thick.

First we do some addition:

- Stroke (4.000 in.) + Ring Stack (.785 in.) + break-point (.525 in.) = 5.310 in. effective piston length

Next we do some subtraction

- Cylinder length (5.430 in) – effective piston length (5.310) = .120 in. (piston remaining at full diameter at bdc.).

Summit Pro LS pistons have more effective piston length in the bore at BDC than other pistons on the market.

*By the way, this taper break-point theory applies to all stroker engines. Ford, Chevy, Chrysler. etc. It’s pretty simple for a good piston designer to look at the ring stack and the intake pocket etc. and determine the maximum stroke an engine builder should pursue.

Will Pro LS pistons make horsepower by themselves?

So far, we’ve talked about strength and durability. Can they also make more power?

- Pro LS piston rings are the very best quality available, but Summit has kept them priced affordably. The steel top ring makes them very durable, yet low friction. They are perfectly round to ensure a full 360-degree seal around the cylinder. This is called light-tight percentage. The Martensitic ductile Napier second ring does an excellent job of controlling oil. This means the oil ring tension can be reduced which reduces friction and increases power.

- The Pro LS piston grooves are precision machined. For optimal ring contact and seal, the grooves must be very flat with a mirror-like finish. In addition, they are cut with a slight positive angle for better ring seal when the lands grow with thermal expansion.

- The valve reliefs and spherical dishes are designed to increase flow around the valves and enhance combustion.

- Summit Pro LS 4.8, 5.3, 5.7, and 6.2L mid-compression pistons increase compression over ½ point before milling the heads. A one-point increase in compression nets a roughly 4 percent increase in power. In the case of a 500 crank horsepower engine, that’s another 20 horsepower for free! Better yet, that’s from idle on up – meaning torque is up everywhere through the range.

How to Pick the Right Pro LS Piston for Your Application

Pistons are generally listed by bore, compression height, and volume. Summit Pro LS pistons take it a step further by giving you the compression ratios for each of the common combustion chamber volumes. This takes the guesswork out of choosing the perfect compression.

The pistons are listed in catalog format. At a glance, they’re divided up this way:

The Summit Racing Pro LS Forged Piston lineup includes:

- 4.8L

- Gen. 3 press-fit rod with .945 pin

- Gen. 4 full-floating rod with .943 pin

- 5.3L

- Gen. 3 press-fit rod with .945 pin

- Gen. 4 full-floating rod with .943 pin

- Standard stroke with aftermarket 6.125 rods with .927 pin

- Stroker crank with 6.125 rods with .927 pin

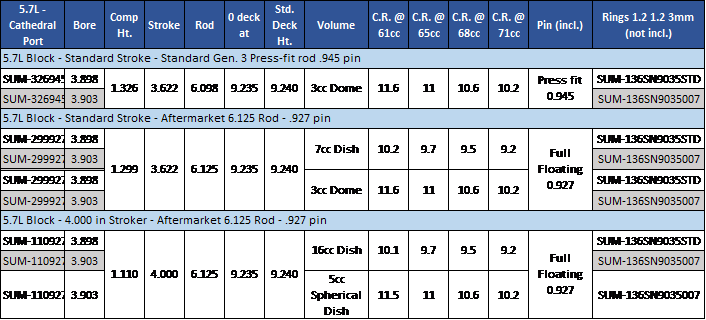

- 5.7L

- Gen. 3 press-fit rod with .945 pin

- Standard stroke with aftermarket 6.125 rods with .927 pin

- Stroker crank with 6.125 rods with .927 pin

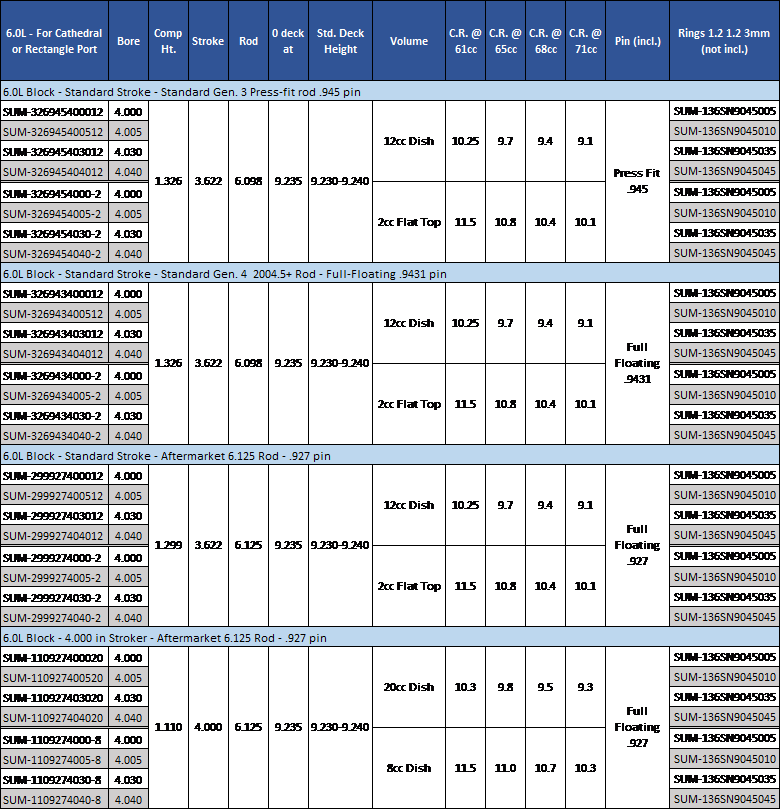

- 6.0L

- Gen. 3 press-fit rod with .945 pin

- Gen. 4 full-floating rod with .943 pin

- Standard stroke with aftermarket 6.125 rods with .927 pin

- Stroker crank with 6.125 rods with .927 pin

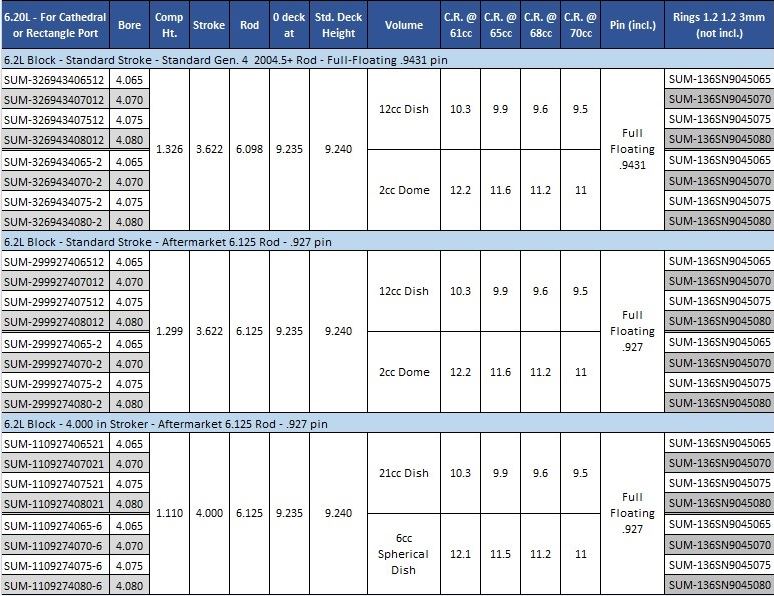

- 6.2L

- Gen. 4 full-floating rod with .943 pin

- Standard stroke with aftermarket 6.125 rods with .927 pin

- Stroker crank with 6.125 rods with .927 pin

Want some more detail by the engine’s original displacement?

Summit Pro LS 4.8L Forged Pistons

Summit Pro LS 5.3L Forged Pistons

Summit Pro LS 5.7L Forged Pistons

Summit Pro LS 6.0L Forged Pistons

Summit Pro LS 6.2L Forged Pistons

…

What Else You’ll Need to Run Summit Pro LS Pistons?

The great thing about the Pro LS pistons is they are designed to work with proven, off-the-shelf components.

Piston rings: Rings are one of the most important components in an engine. They must seal against high combustion pressure and dissipate heat out of the piston. At the same time, they must be thin for low friction. A byproduct of a thin ring is the increased ring land thickness. Summit Racing designed these pistons around the best file-to-fit rings available to ensure the very best performance.

- The top ring material is a Stainless Steel Nitride positive twist. 3L pistons use a 1.5mm top ring while the 5.7L, 6.0L, and 6.2L pistons are 1.2mm.

- The second ring is a Napier style made of Martensitic ductile iron. 3L pistons use a 1.5mm second ring while the 5.7L, 6.0L, and 6.2L pistons are 1.2mm.

- The oil ring uses flex vent technology and the ultimate in oil control. They are 3mm thick and standard tension in all applications.

Wristpins: Summit Pro LS piston kits include .150-inch wall-thickness 5115 alloy pins. These pins are ground accurately with a very nice finish. The alloy is chosen because it’s strength and ductility. These pins are commonly used for high triple digit horsepower on boost, 7000+ rpm, or up to a 250 shot of nitrous.

If you are looking for four-digit power on boost or using a 300+ shot of nitrous .200 wall 9310 alloy tool steel pins are available. Although they can’t be substituted, upgrade thick-wall 9310 tool steel pins can be found on the suggested parts tab on Summit’s website.

Connecting rods: Summit Racing is the first company to offer each piston kit with versions for the Gen. 3 press-fit, Gen. 4 full-floating, and a aftermarket forged 4340 steel connecting rods. No matter what connecting rod you have, you will find a piston that fits.

Crankshafts: Summit Racing Pro LS pistons have versions for both standard 3.622-inch and 4-inch aftermarket stroker cranks. The pistons have special skirt profiles to reduce piston rock and wear to compensate for the extra stroke.

Here’s a few other things that you’ll find handy when assembling an engine:

Does Summit Racing have plans to do there own line of forged connecting rods and cranks for the LS platform.

Hi Scott, Summit now has Pro LS 4340 Forged Cranks and rods to match the piston lineup. The lineup is a little bigger now with the addition of 427 pistons too!

[…] A solution for that emerged earlier this year when Summit Racing introduced its line of 2618 alloy forged Pro LS pistons. […]

You got to laugh!!!.

What about the lot of people that wish to bore out their LM7 to 3.898 (LS1) size using most of their stock components. IE rods crank and heads. All the combinations here BUT not a LS1 piston with a 7cc dish, press fit .945 or floating .943 pin.

This will allow use of the stock, good flowing 706 heads (61cc chamber) with a pump friendly CR of around 10:1 ratio.

Do you have any pistons 4.125 ls7