(Image/OnAllCylinders)

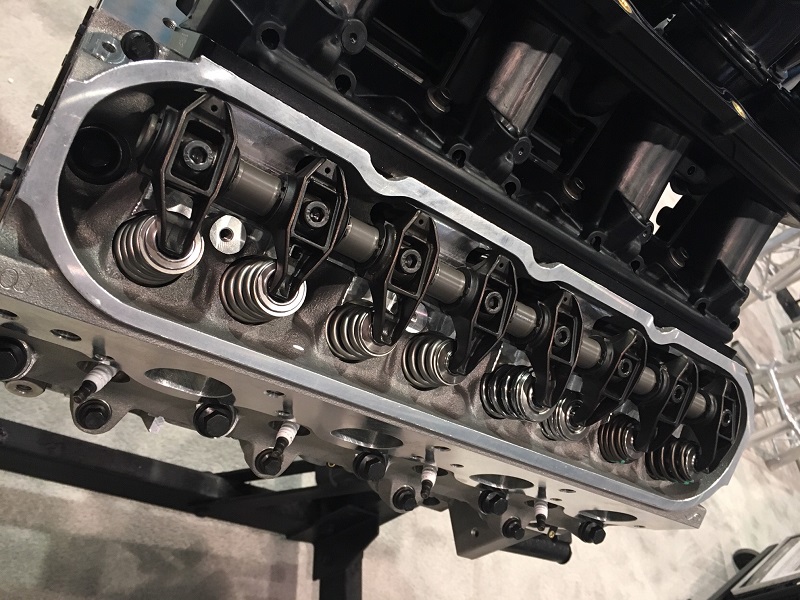

LAS VEGAS, NV — COMP Cams’ introduced a new bolt-in shaft rocker system for high-horsepower, high-lift LS engine applications at the 2018 SEMA Show that provides significant valve train stiffness and reduced deflection to add power and performance to your LS build.

The COMP Cams Max-Lift BSR Shaft Rocker System will make the same camshaft perform like a larger camshaft or allow for swapping in more aggressive camshaft altogether.

COMP Cams designed the rocker system so that pressurized oiling is optional, which would further enhance durability. The patent-pending design is a first for the LS market, company officials say.

The new rocker system is available for purchase now.

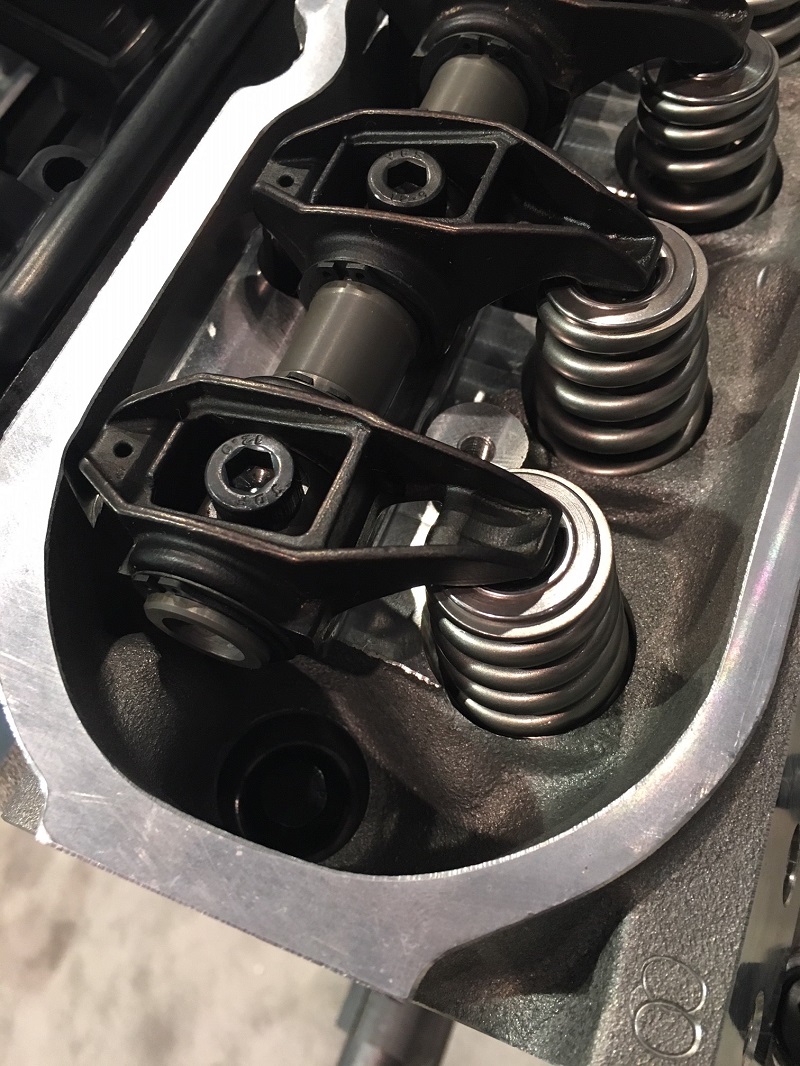

All eight rockers are tied together on a single shaft that is fully assembled with rocker bodies. That assembly fits in the stock rocker stand. Tri-layer bushings, rather than needle bearings, reduce deflection and eliminate the high Hertz loading from needle-bearing trunnions, COMP Cams officials said. This adds rigidity and durability.

The Max-Lift BSR Shaft Rocker System also features a plasma nitride finish which minimizes friction and further improves durability.

The new COMP Cams rocker system is available for the following LS applications:

- LS1 cathedral port cylinder heads

- LS3 rectangular port cylinder heads

- LS7 raised rectangular cylinder heads

The system design transfers more of the lobe lift directly to the valve instead of being absorbed by deflection in the cylinder head and in single-bolt rocker mounting designs.

(Image/OnAllCylinders)

I have a lm7 with 706 heads would this product work on those heads

Yes

How are the valves adjusted ?

You dont adjust valves on an LS lol

I adjust my valve. Solid roller

There are new adjustable pushrods out now from comp that would work great with these.

Unless you have an adjustable rocker arm their is no adjustment. You set you preload by rocker length and go. No need to adjust

What’s the price range for this

Thanks for your question, Bryan. This system will be in the $599.95 – $649.95 range.

what is the correct procedure for installing the shaft rockers . some of the rockers will have spring pressure and some wont . will this be hard on the threads in the head ?

Tighten each bolt 1/4 turn at a time or install studs in the head and do the same thing. Don’t bend the shaft or pull the threads out of your head!