Building a show-stopping custom is no easy task. From the initial concept to the finished product, a project of this magnitude usually takes multiple builds to perfect.

Keith Sayers achieved perfection in his first attempt. This tricked-out 1953 Ford F-250 is loaded to the brim with ingenuity and creativity—it’s a reflection of Sayers’ natural talent.

Growing up around cars, Sayers is no stranger to working under a hood.

“My mom raced stock cars when I was a kid,” he said. “When I got older, I helped my friends work on their mini trucks. I also helped my brother build his ’66 Nova.”

Armed with all of that hands-on know-how and the drive to build himself a vehicle, Sayers began searching for his dream machine. Driving home from work one evening, he spotted an old Ford farm truck for sale.

“I’ve always wanted a ’50s Ford truck. I love the rolling fenders and the mean look of the grille,” Sayers said.

Realizing the underlying potential, he was quick to bring home the retired workhorse. Sayers, a sheetmetal engineer manager by trade, utilized his skills and resourcefulness to bend, shape, and weld steel into this bare-metal masterpiece.

“Whatever parts I didn’t have, I built,” Sayers said. For many, that list would be brief. But Sayers would have saved time by listing what he didn’t create. “I built the frame, bed, tailgate, running boards, and bumpers. The hood, fenders, and cab are original.”

But don’t be fooled, Sayers repaired, reworked, smoothed, or otherwise modified those, too.

“When I found the truck, it had knobby tires and a long bed with wooden stakes,” Sayers said. That may have worked for hauling hay, but Sayers had something else in mind for this metal masterpiece. “I really wanted a short bed, but I also wanted to kick out the rear fenders so they’d sit flush with the front fenders,” he said. So, Sayers did what he does best—he custom-fabricated a bed that simultaneously changes and enhances the F-250’s iconic bodylines.

In a nod to this farm truck’s past, Sayers also added an actuator to the underpinnings of his custom bed. “They were throwing out an old air-powered lift table actuator at work, and they asked me if I wanted it,” he said. Being the resourceful hot rodder he is, Sayers didn’t think twice. With a flip of the switch, the Ford’s bed tilts up in the air like a dump truck, revealing an undercarriage overflowing with details.

Take a peek underneath the one-off bed and you’ll see a setup heavily influenced by Sayers’ race car and mini truck past. The undercarriage is scattered with creative touches, like a triangulated 4-link setup, a differential-mounted disc parking brake, custom-fabricated wiring and fuel line brackets, and so much more.

Rather than cover all of that hard work in paint, Sayers opted to put a satin clearcoat on the raw metal, and it’s truly a sight to behold. “I thought graining out the metal like stainless steel would be cool,” he said. While he originally intended for the sheetmetal to remain clean, it has since taken on a life of its own.

Oxidation has set in underneath the clearcoat, slowly evolving the Ford’s finish. What was once grained sheetmetal has now developed into a natural patina that treats your eyes to hints of bronze, silver, and gold. Each panel looks completely different than the next!

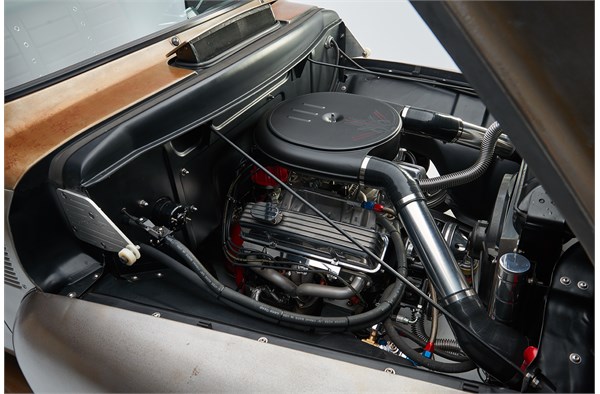

But the truck is more than just looks. Pop the pickup’s reverse-operation hood and you’ll find a bored and stroked Chevy 350.

“The 383 was given to me by my brother for working on his Nova,” Sayers said. “I originally wanted to put a Ford engine in it, but I couldn’t get one for free.”

Sayers topped off his powerplant with ported and polished Dart cylinder heads, a Dart intake manifold, a Mighty Demon 750 cfm carburetor, and a Cadillac-style air cleaner, complete with a custom-built cold air intake and pinstriped accents. It all adds up to an impressive 430 horsepower and 450 foot-pounds of torque!

There was a Saginaw 4-speed transmission mated to the 383, until some hotrod shenanigans ensued. “The kids urged me to do a burnout,” Sayers said. “The transmission case cracked, the output shaft broke off, and it was bleeding all over the ground.”

The transmission was totaled.

Sayers took the hint and beefed up the drivetrain. He opted for a new McLeod 5-speed transmission with overdrive, a McLeod Twin Disc clutch, and a Lakewood bellhousing. While he was at it, he also upgraded the Ford 9-inch rear end with 4:11 ring and pinion gears for better performance and improved cruising.

When it came time to replace the farm truck’s factory leaf springs, Sayers installed a complete air suspension system on all four corners. When he hits the switch, the truck’s frame gently rests on the ground, providing a dramatic look that instantly turns heads. Pulling ideas from the mini trucking world, he also bolted drag plates to the frame so he can drop the bed and make sparks fly!

Inside the all black cab, Sayers natural talent is on display everywhere you look. From the custom-built gauge pods and accessory switch panels to the custom-fabricated kickpanels and factory pedal pad brackets, this Ford’s interior is dressed to impress.

Utilizing the original seat frame, Sayers had a friend wrap the bench seat in black and clay brown leather.

“My buddy stitched the seat for me,” he said. “It’s the only piece on the truck I didn’t build myself. I didn’t know how to stitch.”

But that didn’t last long. Soon, Sayers bought a sewing machine and taught himself how to stitch. Then, when the Ford’s Saginaw blew, he put his newly acquired skill to the test.

“I made the transmission and parking brake boots myself,” he said.

In the end, Sayers’ metalworking mastery, vision, and creativity can be seen throughout his F-250. What was once an old farm truck is now the ’53 showstopper you see today. With an ever-evolving finish and enough custom touches to impress the most gifted fabricators, it’s hard to ignore the ingenuity and natural talent behind Keith Sayers’ crafted work.

Story By: Nick Dinardo

Photography By: Todd Biss

FAST SPECS

Chassis

Frame: Laser cut and fabricated by owner from 3/16″-thick steel

Frame Modifications: Modified C-channel crossovers

Rear End: Ford 9-inch rear end with shortened 31-spline axles, Richmond 4:11 ring and pinion, limited slip differential

Front Suspension: TCI Mustang II-style independent front suspension and stabilizer bar, 2″ drop spindles, Pete & Jakes front shocks, Firestone air bags

Rear Suspension: Triangulated 4-link built by owner, Monroe shocks, Slam Specialties air bags

Steering: Flaming River steering column,

AGR Performance power steering rack and pinion,

billet steering wheel

Brakes: GM Metric slotted and drilled front rotors, US Brakes rear rotors, GM Metric calipers, Russell stainless steel brake lines

Wheels and Tires: American Racing Torque Thrust II 20-inch wheels, Nitto NT555 tires (245/35-20 front, 285/30-20 rear)

Engine and Transmission

Engine: Chevy 350, bored and stroked

Cylinder Heads: Dart cylinder heads, ported and polished

Valvetrain: COMP Cams Thumpr hydraulic roller camshaft, valve springs, and retainers; Scorpion Race Series rocker arms and roller lifters

Induction: Dart intake manifold, Demon Carburetion Mighty Demon 750 cfm carburetor, Cadillac-style air cleaner, custom-built cold air intake system

Rotating Assembly: LPC 4340 crankshaft, Scat H-Beam connecting rods, Mahle pistons, King engine bearings

Ignition and Electrical: Accel HEI distributor, ignition coils, and 8.8mm 300+ Ferro-Spiral race ignition wires; Summit Racing ignition controland Mini High-Torque Starter; Tuff Stuff One-Wire alternator; EZ wiring harness; two 12V Optima batteries

Cooling: OE-style radiator upgraded to a 3-row,Summit Racing electric fan, fan shroud built by owner

Exhaust: Hedman Block Hugger headers with DEI Titanium exhaust wrap, 2 1/2-inch diameter exhaust system made by owner, Flowmaster 40 Series mufflers

Transmission: McLeod Musclecar 5-speed overdrive transmission, RST Twin Disc clutch kit, and pressure plate; Lakewood bellhousing; Hurst shifter and knob

Other Items: Tuff Stuff standard-volume water pump, Cal Custom finned valve covers and breather, engine mounts and accessory brackets custom built by owner

Exterior

Body: 1953 Ford F-250; forward tilt hood; shortened and widened tilt bed, tailgate, running boards, and front and rear bumpers all built by owner

Paint: Bare metal with satin clearcoat, Flat Black Rust Encapsulator

Bodywork and Paint By: Owner

Pinstripe on Air Cleaner By: Jeremy Seanor at Lucky Strike Designs

Other Items: Shaved turn signals, shaved emblems, headlights with built-in marker lights, chrome headlight eyebrows

Interior

Seat: OE seat frame

Upholstery: Black and clay leather by Scott Zielinkski

at Sew It Seams

Carpet: Black carpet, kick panels fabricated by owner

Dashboard: Heater control, air suspension panel, and trim pieces fabricated by owner; deleted radio

Gauges: Dolphin gauges and gauge panel, gauge pods built by owner

Shift and Emergency Brake Boots: Black leather, made by owner

Stereo: Secret Audio

Performance

Horsepower: 430 horsepower @ 5,500 rpm

Torque: 450 ft.-lbs. @ 5,500 rpm

Special Thanks

My wife Heather, and my kids Trent and Camryn.

Thank you for being so supportive.

[…] http://www.onallcylinders.com/2016/10/18/crafted-work-keith-sayers-1953-ford-f-250/ […]