Everybody that has Ford blue running through their veins loves the 5.0L Coyote. And with good reason—a production Coyote makes 435 horsepower and 400 ft.-lbs. of torque, and they’re readily available in crate engine form.

But that doesn’t mean the older 4.6L Ford modular motor has to choke on the Coyote’s dust. In fact, Trick Flow Specialties has built a 5.3L 2V that makes plenty of power on 93 octane gas, features all-new parts, and is practically a drop-in for any 1996-2010 Mustang. Interested?

The build is based on the Ford Performance 5.3L Modular Short Block Assembly. A stout foundation for any 2-, 3-, or 4V modular build, the 323 cubic inch short block is assembled from all-new parts:

- BOSS cast iron block

- Eagle Specialties 3.750-inch stroke forged steel crankshaft with 8 bolt flywheel

- Eagle Specialties 5.850-inch forged steel H-beam rods with ARP 2000 bolts

- Mahle forged aluminum dished pistons compatible with 2- 3-, or 4-valve heads

- New high pressure oil pump

A lot of 4.6L-based builds rely on a supercharger or other power adder to make good horsepower figures. What makes using the Ford Performance short block an interesting proposal is the fact that it’s a great foundation for a high compression, naturally aspirated engine. Here are the compression ratios using factory heads:

- 44cc 2V: 11.56:1

- 51cc 3V: 10.5:1

- 53cc 3V: 10.2:1

- 53cc 4V: 10.2:1

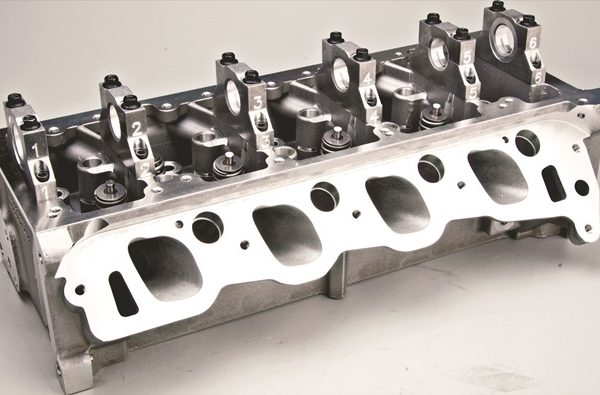

Trick Flow took a trip through its parts bin and came up with a top-end package that takes advantage of the high compression characteristics of the Ford Performance short block:

- Twisted Wedge® Race 195 2V cylinder heads, 44cc combustion chamber

- Track Max® Stage 2 camshaft set, .580 inch lift/234° duration @.050 inch

- Track Heat® EFI intake manifold

- Track Max underdrive damper and pulley kit

- Timing chain set

- Cam followers and hydraulic lash adjusters

On the dyno with a dual 57mm throttle body, 70mm Mass Airflow sensor, 36 lb.-hr. Ford Performance fuel injectors, and a pair of Pace Setter 1 3/4 inch primary tube headers, the 5.3L made 466 peak horsepower and 414 ft.-lbs. peak torque.

Put that in a lightweight SN95 or New Edge Mustang and you’ll have a lot of fun. Summit Racing has even made it easy by creating 5.3L Ford Modular Engine Combos.

nice combination for the 4.6 the numbers are impressive it sort of gives me a base line on the 5.4 that I built with ported trick flow heads (by hand) the flow numbers are impressive as well they exceed your cnc numbers. H-beam rods, manly pistons 12-1 compression, victor jr intake, BBK 78 mill throttle body, 90 mill mass air, 36 lb injectors, 1 7/8 ” primaries to a 3″ collector long tube headers. I can’t wait to get it on the dyno. Keep in touch Ed

Ed, what was the TFS model # and chamber size for your 5.4L build? I am building a 5.4L 2V engine based on a stock 2008 GT500 short block and am trying to figure out which TFS to use. I’m using a Comp Cams XE278AH Camshaft along with 3.73 gears in the rear along with a 2400 stall speed converter in a Ford 6spd automatic transmission. Your help is appreciated.

Hello John, my apologies for the lack of communication. Twisted Wedge Race 195 2V cylinder heads, 44cc. I’ve made some changes to my set up, i.e. went with a 43lb injector, dual 255 walbro fuel pumps. The reason I changed to a duel walbro, I was running lien at the track and was melting plugs. I burnt the exhaust valve on cylinder #4. The 60′ 1.4 at the 1/8th mile it would do a face plant(embarrassing)anyway, edlebrock fuel rails, external fuel regulator, 3″ carbon fiber cold air kit,(made it myself) looks serious. I do have 3.73 gears. I did have it on the dyno before all the changes 350 hp, 375 lbs of torque to the rear wheels. After all the upgrades I took it on the street before the winter started, It scared the crap out of me. I was on the hwy cruising around 70mph matted it and the ass end brock loose, (street tires-ZR295-40-18)well that was fun. It’s March 11, 2019 our track opens in April. I’ll let you know what it does with nitrous and with out. cheers, Ed

I’m looking for a 4.6L ford expedition timing cover. 2003

Perfer new.i need help

Ever get that on the dyno?

Allan, I had it on the chassi dyno made a modest 350 power and 375 torque to the wheel. I was running real lien had to change the fuel pump set up duel 255 walbro, changed to a 43lb injector, put a custom made 3″ carbon fiber cold air kit, got it tuned by JJ at Woodbine motor sports. I’m looking forward to going to the track this April. I’ll keep you in the loop. Cheers, Ed

Hey any new time on your car at the track.

Does it still weigh 685lbs and have 30″ width at the valve covers? How about an SN95 Mark IV chevy swap?

Take chevy talk elsewhere!!

Yes, I really dont get the Chevy swap. It makes little sense unless your mod motor and the heads are destroyed and you just so happen to have an LS laying around or were given one.

Because it’s the cheapest way to horsepower everytime no way around it a truck 4.8 with a carburetor and stock exhaust manifolds just a cam swap and boom 400 horsepower

How hard would it be to put this 5.3 in a 1995 Thunderbird

It bolts in since it uses a heavy duty 4.6 block

I just installed this setup in a 95 tbird it’s almost a direct swap gotta mod the motor mount brackets to clear the block but that’s it

What modifications would be required to install into an 05 Crown Vic?

I’m rebuilding a 5.4l iron block out of a 2000 Harley-Davidson edition. I’m looking for a stroker set up. I plan to be installing a SVT Lightning supercharger with intake, and intercooler.

Any one out there got any ideas

Vic Forster

I’m putting a 1954 F100 on the harley chassis.

What is the compression with the 38cc heads. How much boost would you recommend from a procharger p1sc?

I’m pretty sure a 331″ pushrod 8.2 block engine with the right heads, intake and carburetor will out-power it, out torque it across the rpm spectrum, be less expensive and a lot smaller, making it easier to put in any Mustang. Not to mention what a 347 would do to it.

Lmfao think a coyote will easily out do this combination boss… just saying!! 10k build smh.

Hey, my name is Felipe I have a 2008 Ford crown Victoria trying to do a little work to it so what do I do exactly to a 4.6 star engine my number is 305-397-6330. Please help LOL.