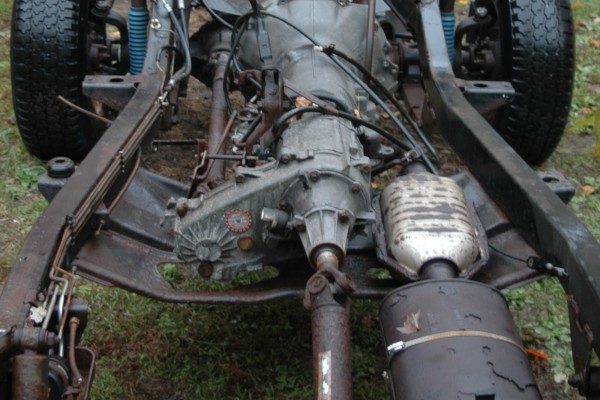

OnAllCylinders readers might remember when we began our 70,000-mile 1994 Jeep Wrangler Sahara project by giving it a frame-off restoration by stripping and recoating the frame with KBS products. That was a while ago, and life and weather conspired to put the project on the proverbial back burner. But now that both have returned to some sense of normalcy, we’ve gotten back to it.

In this two-part article, we’ll show you how we transformed that frame into a complete rolling chassis. It’s not as hard as you think, and all of the parts are readily available. Even if you don’t own (or like) YJs, much of the rehab process is similar to what you would do on a TJ, or even an old CJ.

So let’s get right to business.

[…] Part One of YJ Rehab, we showed you how to restore the suspension and upgrade the fuel system on a 1994 Jeep Wrangler […]