EDITOR’S NOTE: What are the top high performance automotive parts of all time? Or in this case, what are the Top 20 most iconic parts that changed hot rodding? We’re talking total game-changers in the annals of our hobby.

We asked a panel of OnAllCylinders staffers, longtime automotive journalists, and veteran members of the Summit Racing technical and marketing departments for their input. The countdown continues with number 3 (you can see numbers 20 through 4 here).

It seems like Edelbrock has been around since the dawn of hot rodding.

The name Edelbrock is synonymous with high performance and the company is arguably the most influential brand in the aftermarket industry. Amazingly enough, the company’s considerable legacy and success was launched by a slingshot—the Slingshot intake for Ford Flathead V8s!

Edelbrock was primarily a repair shop in 1938, when Vic Edelbrock Sr. acquired his first project car. This Flathead-powered 1932 Ford Roadster was Edelbrock’s first foray into the world of hot rodding and inspired the development of Edelbrock’s first “aftermarket part,” the Slingshot intake manifold.

“Vic was originally involved with a guy named Tommy Thickston to come up with a manifold for the Flathead,” said Smitty Smith, Edelbrock Technical Sales Coordinator and resident historian. “When Vic wasn’t happy with the performance from this design, he designed his own aluminum manifold. It was a different time…there was no engineering as we know it. There was a lot of drawing on napkins, and (Vic) didn’t want it to interfere with the Monday-Friday business, so he did it in his spare time.”

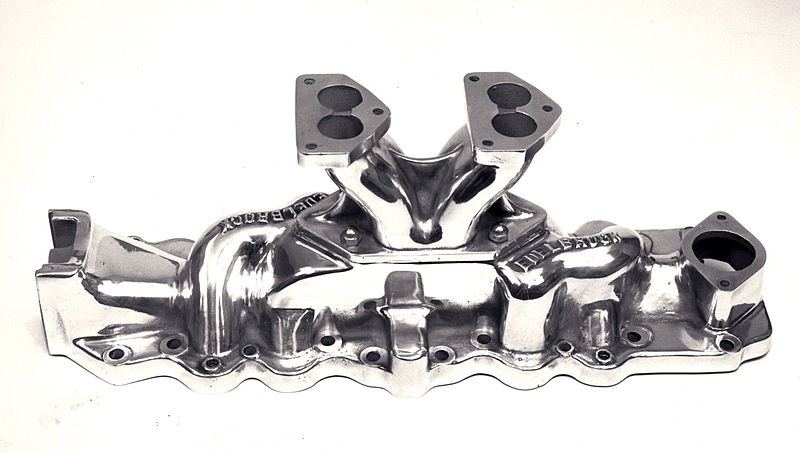

Edelbrock came up with a design that featured a 180-degree manifold with two Stromberg 97 carburetors. These carburetors sat on a unique carb mount that resembled a slingshot without the rubber band. Hence, the legendary Slingshot name.

“(Vic) wanted something he knew would perform better,” Smith said. “The Slingshot balances out the intake distribution, just like an X-pipe equalizes pressure from side-to-side. It also has a cut-down center divider to improve the fuel atomization at high rpm.”

This new manifold was the first of many products to feature the “Edelbrock” name.

As Edelbrock Sr. continued to race and test his new manifold on the dry lakes of El Mirage in California, people began to take notice of its performance benefits. Between 1938-41, Edelbrock made about 100 Slingshot manifolds. Following World War II, Edelbrock built off the success of the Slingshot manifold to create other Flathead V8 parts, and the company transitioned from repair shop to a “power and speed equipment shop.”

“He learned in World War II how machining could make a good product,” Smith said. “He used this knowledge to come up with new cylinder heads. At the time, Ford used what was called “Denver” cylinder heads. The Flathead didn’t run well at elevation, so Vic took the Denver heads and milled them for higher compression.”

Edelbrock began offering aluminum cylinder heads for Flathead V8s. Other Flathead parts would follow, and then Edelbrock began to apply its knowledge and experience to other engine platforms, including the new small block Chevy in the 1950s. Today, world-famous Edelbrock engine parts can be found for virtually any American V8 engine. Plus, the company offers carburetors, suspension components, and many other items.

But it all started with the legendary Slingshot intake manifold.

“This is the intake that truly started the performance induction market and began pushing Vic Edelbrock Sr.’s shop away from repairs and into one of the world’s first speed parts manufacturers,” said OnAllCylinders contributor Christopher Campbell.

The Slingshot inspired generations of hot rodders to swap out their performance-limited stock manifolds. “Edelbrock, Weiand, Offenhauser, and about a zillion other companies made aluminum manifolds for virtually every American engine produced in the 1930s onward,” said Alan Rebescher, PR/Media Relations for Summit Racing. “Those manifolds gave hot rodders the ability to feed their engines more air and fuel and produce more horsepower. They also weighed a lot less than OEM cast iron lumps, saving a few pounds.”

Smith is quick to point out the design of the Slingshot still stands up today.

“We brought the Slingshot back in 2004 or 2005,” Smith said. “(Vic Jr.) didn’t want to change it, so we just added the ‘Made in the USA’ stamp. Street Rodder magazine did a Flathead Shootout recently with different manifolds, and it still held its own!”

Historical—and still relevant—the Edebrock Slingshot intake manifold is #3 on our list of Top Aftermarket Parts of All Time.

Hi David, nice job you did here. I feel it turned out pretty darn good.

Thanks again – Smitty Smith Edelbrock

Thanks for your time on this. It was a pleasure talking to you. Glad you like it.

Nice work. Great read. – Bobby Kimbrough

Thank you, Bobby.

[…] Read David Fuller’s article here […]