EDITOR’S NOTE: What are the top high performance automotive parts of all time? Or in this case, what are the Top 20 most iconic parts that changed hot rodding? We’re talking total game-changers in the annals of our hobby.

We asked a panel of OnAllCylinders staffers, longtime automotive journalists, and veteran members of the Summit Racing technical and marketing departments for their input. The countdown continues with numbers 6 through 10 (you can see 16-20 here and 11-15 here).

#10: Crane Roller Rockers

Roller rockers arms are one of the most common performance upgrades. We can thank Harland Sharp for first introducing the roller rocker arm in the early 1960s. Shortly after, Crane Cams came out with a more refined and reliable design that made roller rockers a viable option for the masses. They reduced friction and wear and fostered more reliable high-rpm performance.

Roller rockers arms are one of the most common performance upgrades. We can thank Harland Sharp for first introducing the roller rocker arm in the early 1960s. Shortly after, Crane Cams came out with a more refined and reliable design that made roller rockers a viable option for the masses. They reduced friction and wear and fostered more reliable high-rpm performance.

Today, Crane Cams, Harland Sharp, and others, offer high-quality roller rocker arms. But it was Crane that really popularized this upgrade and used its already-extensive industry connections in the 1960s to proliferate roller rockers. It’s worth noting that Crane would go on to develop high-quality roller lifters—another step forward in high-rpm performance.

“Crane wasn’t the first to offer roller rockers to the masses (Harland Sharp built the first ones in 1960), but they popularized them. They had a large dealer network and their extrusions were always very high quality. Another home run, and they’re still available today.” –Wayne Scraba, OnAllCylinders contributor

#9: NOS Nitrous Systems

In the aftermarket industry, the words nitrous and NOS are often used interchangeably. That’s because Nitrous Oxide Systems (NOS) is the company that put nitrous systems on the map as a safe, potent power adder for vehicles.

In the aftermarket industry, the words nitrous and NOS are often used interchangeably. That’s because Nitrous Oxide Systems (NOS) is the company that put nitrous systems on the map as a safe, potent power adder for vehicles.

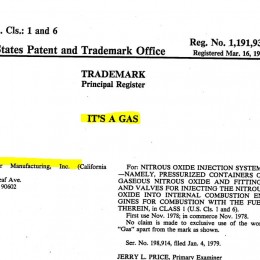

Nitrous had actually been used as a performance enhancement as far back as World War II. It was used in the 1960s and 70s with mixed results—Summit Racing even sold nitrous kits from Marvin Miller, who had filed for a trademark patent in 1978 (see below right). However, NOS was the first to prove that nitrous oxide could be used safely and effectively on a consistent basis. And it was NOS that perfected the turnkey nitrous system and turned it into a popular, bang-for-buck performance part.

“The basic 150-horsepower, single four-barrel plate system turned more slugs into quick street cars than any other product on the market since the invention of the cheater slick,” said longtime automotive journalist Jeff Smith. “Plus, now you can make up to 500 horsepower with a single plate and control it with a PWM controller to act like a multi-stage system!”

Since 1978, NOS nitrous systems have changed the world of drag racing, creating new racing classes and helping doorslammers go 200 mile-per-hours. Several decades and many Fast and Furious movies later, we refer to nitrous oxide systems as NOS—pronounced NAAAHHHSSS.

“Nitrous oxide got a bad rap back in the late 1960s and early 1970s due to poor quality kits and backyard setups that routinely melted engines. Companies like NOS developed nitrous systems that made big horsepower in a safe, reliable manner.” –Alan Rebescher, Summit Racing PR/Media Relations

#8: Hooker Super Competition Headers

Gary Hooker wasn’t the first to use exhaust headers, but he was the first to truly realize the performance potential and make it mainstream. Hooker developed his first header for his 409 Chevrolet in 1962 and demand for his design quickly spread among Southern California racers.

Gary Hooker wasn’t the first to use exhaust headers, but he was the first to truly realize the performance potential and make it mainstream. Hooker developed his first header for his 409 Chevrolet in 1962 and demand for his design quickly spread among Southern California racers.

Hooker Headers dominated drag racing in the late 1960s and 1970s, with nearly all NHRA Pro Stock racers winning with the company’s headers. Racers like Grumpy Jenkins and Sox & Martin were Hooker customers, and equal-length Super Competition headers are still available for a wide range of applications today.

The name Hooker remains synonymous with headers.

“Hooker wasn’t the first at building headers, but they were one of the first to take the performance end of it seriously and simultaneously back it up with a marketing and production plan to make quality headers available to the masses. Another hit.” –Wayne Scraba, OnAllCylinders contributor

#7: Iskenderian Camshafts

Ed Iskenderian earned the nickname, “Camfather.”

Ed Iskenderian earned the nickname, “Camfather.”

Iskenderian made performance camshafts, and solid-roller cams specifically, a drop-in upgrade. Iskenderian pioneered the use of computers to design cam profiles. This concept helped take cam grinding from a custom modification to an off-the-shelf upgrade. In short, Iskenderian helped make the modern camshaft and associated valvetrain components some of the most upgraded parts in the aftermarket industry.

Iskenderian also patented the first self-guided roller lifters in 1956, making it easy for more people to run a roller cam. He also developed offset keyways and bushings, antiwalk buttons, and rev kits. By paying racers who won with his cam and valvetrain parts, Iskenderian Camshafts also helped introduce us to the concept of racing contingency—something sportsman racers survive on today.

“Before Isky began offering its own catalog of camshaft profiles, typically the cam business was centered around custom cam profiles specifically ground for a certain application. Now someone looking for more performance out of their engine could simply open a catalog and pick out a camshaft designed by the experts to suit their needs, with no knowledge of camshaft profiles required. This would end up making the cam and valvetrain business one of the pillars of the automotive aftermarket, even to this day.” –Patrick Hill, OnAllCylinders contributor

#6: Hurst 4-Speed Shifter

The Hurst 4-speed shifter is larger than life in the aftermarket world—literally. In fact, a giant version of the iconic Hurst shifter mounted on top of a convertible could be seen at many big-time racing events in the 1960s. The image of Miss Hurst, Linda Vaughn, standing next to the oversized shifter (see below) is probably seared into the minds of old school racing fans!

The Hurst 4-speed shifter is larger than life in the aftermarket world—literally. In fact, a giant version of the iconic Hurst shifter mounted on top of a convertible could be seen at many big-time racing events in the 1960s. The image of Miss Hurst, Linda Vaughn, standing next to the oversized shifter (see below) is probably seared into the minds of old school racing fans!

The Hurst 4-speed shifter earned its gigantic reputation by changing the way manual floor shifters performed. “Factory manual transmission shifters were sloppy at best in the 1950s and 60s,” according to Summit Racing’s Alan Rebescher. Hurst changed all that and gave positive gear-changing to the world with its line of manual shifters.”

Hurst became a major player in the hot rodding community when Pontiac selected a four-speed Hurst shifter for its 1961 Catalina with the 421 Super Duty engine. This original relationship with OE manufacturers helped Hurst become a household name and would lead to near-legendary status for both Hurst and its shifters. The Hurst 4-speed shifter, with its chromed stick and cue ball-style shift knob, could easily be the symbol for aftermarket performance.

Hurst became a major player in the hot rodding community when Pontiac selected a four-speed Hurst shifter for its 1961 Catalina with the 421 Super Duty engine. This original relationship with OE manufacturers helped Hurst become a household name and would lead to near-legendary status for both Hurst and its shifters. The Hurst 4-speed shifter, with its chromed stick and cue ball-style shift knob, could easily be the symbol for aftermarket performance.

“Most floor shifters that came on production cars were junk. Missing third gear was pretty common. But Hurst’s Competition/Plus changed all of that. It was another game changer.” –Wayne Scraba, OnAllCylinders contributor

Check back for numbers 5 through 1 soon.

Comments