In the first segment of Desert Bronco, we introduced Marc Sorger and the 1984 Bronco he was cutting up, er, modifying for desert and short-course racing in his home state of Oregon.

As Marc explained in that story, the 1978-96 full size Broncos are popular as desert racers and prerunner vehicles due to their body-on-frame construction, a Twin Traction Beam front suspension that offers superior wheel travel over a solid front axle, and ability to swallow big engines and drivetrain upgrades. Oh, and they’re cheap.

Marc began the conversion of his ’84 Bronco from old truck to desert racer by adding a Skyjacker Softride two inch lift kit with Nitro shocks front and rear to add some suspension travel and make room for the 33.5 inch tall Maxxis Bighorn tires and Pro Comp Xtreme Rock Crawler wheels. He swapped out the old 302 small block for a 331 cubic inch motor that makes about 350 horsepower, patched the front driver side floor, and installed a set of Summit Racing race seats.

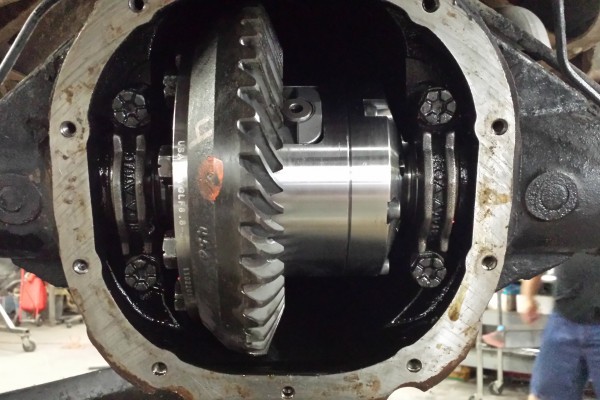

In this segment we’ll show you the rest of the build—eight-point roll cage, axle upgrades and locking hubs from Yukon Gear, bumpers and light bars, some black paint, and a pair of G-Force harnesses.

Marc’s recipe is a great starting point for building a very off-road capable Bronco. Depending on how many creature comforts you retain, you can build a truck suitable for street use as well.

Really cool build, very similar to what I’m building now. Mines a1980, 331 with a 4 speed manual.

Really was hoping to read what was done for the clutch, no upgrades over stock/oem?