A while back we brought you the story of Mike Ondish and his quest to restore the hot rod of his youth, a 1968 Mustang GT nicknamed The Demon.

Here’s a quick recap: the Mustang was infamous in the late 1960s and early ‘70s as the ride of choice for Mike and his friends, tempting heaven and raising hell street racing and rum-running through sleepy hamlets in the Catskill Mountains of New York State. Mike put The Demon away in 1975 and settled down to a quiet life as the owner of a repair and restoration shop specializing in early Fords.

Thirty-seven years after it last turned a wheel in anger, The Demon is getting a new lease on life—and the rebirth is being documented in the upcoming film Demon on Wheels.

Which brings us to this story. The Mustang came from the factory with a 390-cubic-inch FE big block. Mike’s idea for the car was to turn it into a (sort of) street-legal Trans Am racer. The 390 got a good going-over, including a Shelby dual quad intake, a pair of modified Holley carburetors, ported and polished 428 Police Interceptor heads with Iskenderian valvetrain gear, and an Isky 505 solid lifter cam. The stock pistons were replaced with Jahns popup pistons that netted a 14:1 compression ratio. Mike brewed his own fuel—a mixture of Sunoco 260 gas, alcohol, and naphthalene—to feed the high-strung beast.

Fast-forward from 1968 to today. The 390 obviously needed a rebuild as part of the Mustang’s rebirth, and Mike took the opportunity to build an engine that would make tons of power, but with far better street manners than it had back in ’68.

“We didn’t have the technology back then that we have today,” Mike said. “Old hot rodder tricks, like raising compression to very high levels, just aren’t necessary anymore. Now you can buy parts off the shelf to build an engine that makes a lot of horsepower, but can run on pump gas and actually idle and run around town.”

The Parts List

And that’s what Mike set out to do. With the help of the tech gurus at Summit Racing Equipment, he put together a parts combination that should be good for about 600 horsepower at the rear wheels. The big-ticket items include:

- Scat balanced rotating assembly with Mahle 10.5:1 flat top pistons

- Comp Cams hydraulic roller cam kit

- Edelbrock Performer RPM aluminum cylinder heads

- OEM Shelby dual quad aluminum intake manifold with 600 cfm Holley carburetors

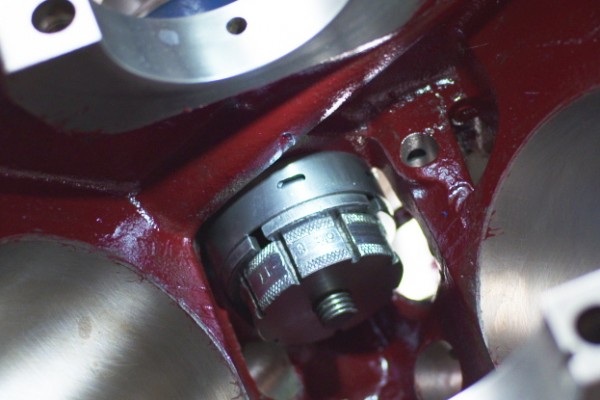

- Summit Racing Street & Strip Billet Distributor

- JBA Competition-Ready Tri-Y headers

- Canton Racing Road Race wet-sump oil pan, Sealed Power oil pump, Canton windage tray and pump pickup

Attached to the 390 is a Tremec TKO 600 five-speed transmission with a Centerforce clutch and a Quick Time bellhousing. The transmission in turn is linked to a Currie 9-inch Ford rear axle assembly with a Currie gear case loaded with 3.50 gears and a Traction-Lok differential.

If you want to duplicate this drivetrain build, Summit Racing has created Demon on Wheels Mustang Combos with these parts plus fasteners, gaskets, and external accessories to make the job an easy one.

Go mike go… waiting to see the documentary… this cousin is chomping to see the demon in person this summer when I come home to visit.. been to long

Any update on the release?

no way in a million years will that 390 put down 600hp to the wheels!

Early on he claimed when he bought the mustang it was 500hp then after mods made

863hp. Complete and total BS!

Why is it bs i have a 60 over 390 with some good c6ae-r heads biger valves an port an polish job the rest is my secret it revs 6500 all day 557 hp no stroker kit 378 crank

I agree with you, it’s not as, I have a .020 over 390 that cranks out 525 hp all day with ported self C4Aeg heads and a Holley SD at 10.25 to 1 20 years of hard running no end in sight.