I am building a 355ci small block Chevy and considering which piston to use. I’m leaning toward a set of stock replacement cast pistons with four valve reliefs. What I don’t understand is why there are four reliefs when I only need two. I’m thinking that it might be so the same piston can be used on both sides of the engine without changing the way the piston is made. Looking at the Summit Racing catalog shows a ton of choices and most of the pistons look the same. I just want to make the best decision. Can you help?

T.C.

This is a great question. And you are right—when we looked up 350ci small block Chevy pistons on the Summit Racing website, we found lots of choices. You are also correct that the reason for the four valve reliefs is so the manufacturer can make one piston that can be used on either bank of the engine. For a set of pistons with two valve reliefs, the left- and right-side pistons are different because of the wrist pin offset intended to reduce piston slap when the engine is cold.

The small block Chevy also places the intake and exhaust valves differently in left- versus right-hand side cylinder heads. To accommodate this, the reliefs in four-relief pistons are the same size to they can clear either valve. All of this adds volume. In checking several pistons, we noticed that the four-relief pistons all claim an additional 6cc of relief volume. This adds combustion chamber volume, which you need to account for when you compute the compression ratio.

Pistons with two valve reliefs don’t seem to drastically reduce relief volume. Most of the ones we looked at list the relief volume at 5cc, which is only 1cc less than most pistons with four-valve reliefs. This 1cc difference won’t have a major impact when computing compression ratio.

There’s much more to this question than just valve relief volume. What many fail to think about is the difference in the piston’s compression height. This is the distance from the centerline of the wrist pin to the flat portion of the piston top. In looking at several cast and hypereutectic pistons, we saw compression height distance vary significantly. This is important for making compression.

Let’s explain how this works.

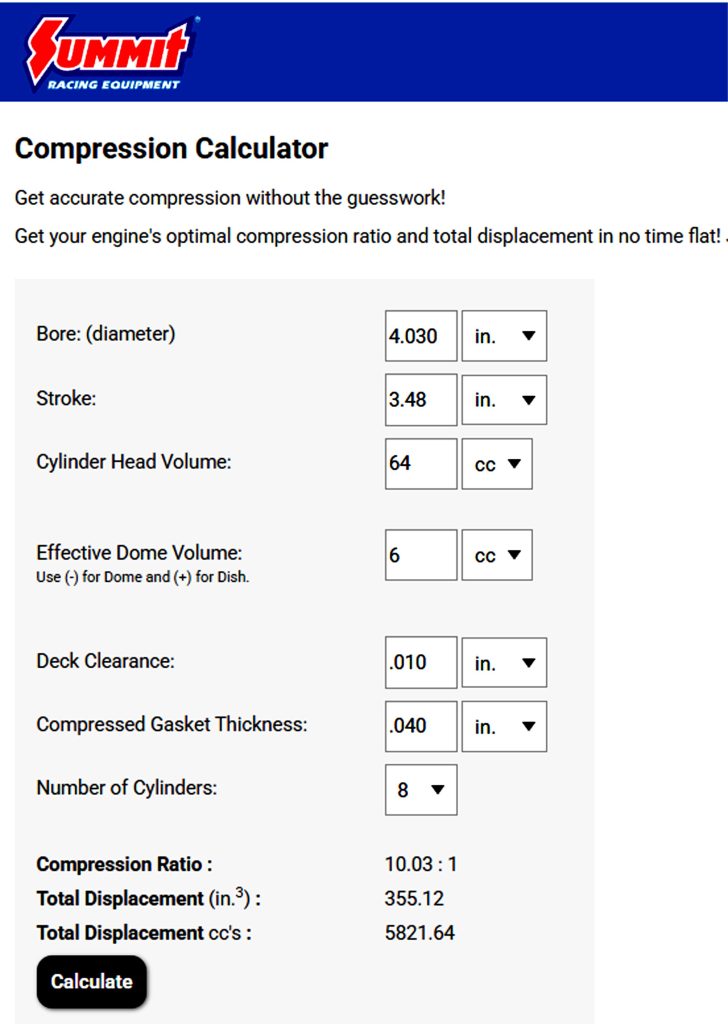

We like to use Summit Racing’s online compression ratio calculator. The inputs are bore; stroke; combustion chamber volume; effective piston volume (dished or domed); deck height; and head gasket compressed thickness. The calculator also asks for the number of cylinders. This isn’t used to compute compression, but it is used to calculate engine displacement.

As we explained, valve relief volume effectively increases combustion chamber volume. For a small block Chevy with 4.030-inch bores and heads with 76cc combustion chambers, a four-eyebrow piston would increase the chamber volume to 82cc. For the same engine using flat top pistons with no reliefs, the chamber size would stay at 76cc and compression would increase.

Another variable is the deck height. Deck height for a stock small block Chevy is 9.025 inches. We can approximate how close the top of the piston will be to the deck with some simple math. Here is the formula for determining piston deck height:

Stroke ÷ 2 + Connecting Rod Length + Piston Compression Height = Piston Deck Height

As an example, the 350 Chevy’s stroke is 3.48 inches, so half would be 1.74. If we add a rod length of 5.70 inches plus a compression height of 1.55 inches, we get a piston deck height of 8.99 inches.

Theoretically, this would place the piston 0.026-inch below the deck surface of the block. We say theoretically because we are working with multiple variables. First, it’s possible that the block deck height is actually shorter or taller due to production tolerances. The calculation also assumes the rod length is exactly 5.70 inches, which may or may not be accurate. All of this can add up to change the actual piston deck height.

This is why checking the actual piston deck height is so important when computing compression ratio. Generally, most stock replacement pistons will sit between 0.015-inch and 0.020-inch below the deck. But you must check to this number if you want your compression ratio calculations to be accurate.

Another major variable is that piston companies set their compression height at different points. We’ll do two compression ratio calculations with two different pistons. We will assume a 9.025-inch block deck height and head gaskets with a 0.042-inch compressed thickness.

Piston One has a 1.54-inch compression height. This will give us 8.98 inches of piston deck height and (theoretically) place the piston 0.045-inch below the deck surface. That produces a 9.24:1 compression ratio—not bad, but it could be better. When we add the 0.042-inch head gasket to the 0.45-inch deck height, piston-to-head clearance comes out at a very wide 0.087-inch.

Now let’s look at Piston Two with a taller 1.565-inch compression height and a block decked 0.010-inch (9.015 inches). This places the piston higher in the bore with a piston deck height of 0.010-inch. With all the other variables the same, this simple change of piston height will increase the compression ratio from 9.24:1 to a surprising 9.98:1. That’s three-quarters of a point! We also radically improved the piston-to-head clearance to a much tighter 0.052-inch. Numbers vary but a really tight quench would be around 0.035- to 0.040-inch.

If we haven’t confused you enough yet, you can play with head gasket compressed thickness to alter compression ratio. Let’s say you have a mild engine with cast pistons and a set of stock iron heads. Instead of using a head gasket with a 0.042-inch compressed thickness, consider using a stock steel head gasket that measures 0.015-inch thick. This thinner gasket moves the head 0.025-inch closer to the piston, which will raise the compression ratio much like moving the piston closer to the deck. With a 76cc chamber head and a piston with 6cc valve reliefs sitting .030-inch below the deck, using this thinner head gasket will change the compression from 8.49:1 to a much healthier 8.95:1.

While valve reliefs do affect static compression ratios, you really need to look at all the variables involved to maximize the results. While it’s additional work, the effort will pay off with better performance.

Comments