I screwed up and over-revved my LS6 motor in my 2000 Camaro and I think I broke a piston. I was lucky and there was only minor damage to the cylinder wall that I think will hone out. What are my options for rebuilding this engine? If the cylinder wall is more severely damaged, can the aluminum block be sleeved or, would I be better off to upgrade to a larger 6.2L engine?

If the engine is rebuildable, I certainly will want to go with a bigger cam and maybe some cylinder head work. Any suggestions?

B.C.

***

Accidents happen. It’s part of the game we play. Let’s look at some facts.

Upgrading to a 6.2L

The LS6 is a 5.7L (346ci) engine while a 6.2L (376ci) is significantly bigger. Think of this like a comparison between a 350ci small block and a 383 Stroker. However, with the LS, the difference is all in the larger bore size since the two LS engines share the same stroke at 3.62 inches. The LS6 uses a small 3.898 inch bore while the LS3 6.2L is significantly larger at 4.065 inches.

Used LS3 6.2L engines are available but they are in high demand. We’ll assume that you will want to remain with a typical Gen. III or Gen. IV engine, as opposed to the more modern Gen. V engines with direct fuel injection. One of the hassles of choosing a 6.2L engine will be converting over to a Gen. IV 58X style crank trigger control system, as your LS6 is the older Gen III system that uses a 24x crank trigger wheel.

These two systems are not compatible but there are ways to upgrade from 24X to the newer 58x. Lingenfelter sells a conversion box that will allow this. The 58X 6.2L engine will also have electronic throttle control while your LS6 uses cable throttle. You’re looking at a used engine prices of $4,000 to $5,000 plus the cost of doing the conversions to a 58x package. That will be considerable and it might eventually run as high as $8,000 to $9,000.

All these details can create multiple problems that may be costly to manipulate if you want to go with the newer and larger Gen IV 6.2L engine. There will be other issues as well with tuning that will need to be addressed.

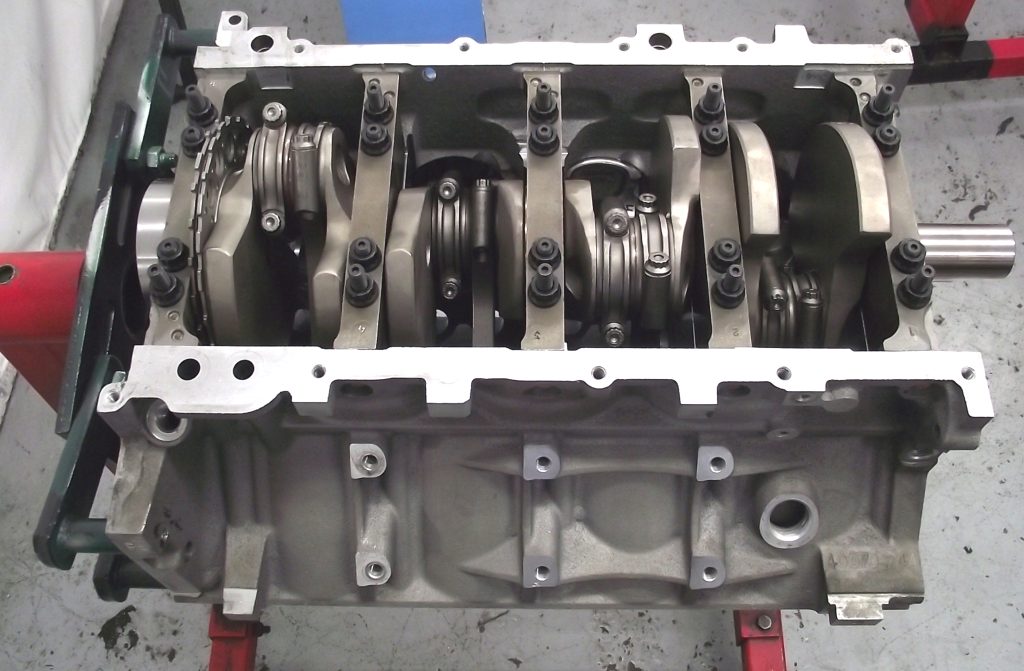

Rebuilding the LS6

A slightly more involved but less expensive route would be to rebuild your existing LS6. We’ll assume as you mentioned that the block and cylinder wall will not have any life-ending damage. If the block is broken then the costs will obviously increase.

Let’s assume the best that the piston has failed, but the engine and cylinder block are salvageable. If the cylinder wall is not damaged, these engines tend to offer really good wear protection and with the more modern engine oil these stronger cylinder wall rarely display a ridge at the top of the cylinder. If so, you might get away with merely bottle brush honing the cylinders and replacing the piston that is damaged.

All but the high output supercharged LS engines use a hypereutectic piston. At first I was skeptical of these pistons as I’ve had not the best luck with hypereutectic pistons in several budget small-block Chevys. But the LS engines seem to be a little stronger in this department. We’ve only broken one LS hypereutectic piston and that was our fault with an 8,000 rpm over-rev!

Go Stroker

Assuming the block is usable, think about upgrading the displacement with a Stroker crank. The stock stroke on a 5.7L engine is 3.626 inches which is almost 0.150 inch longer than a standard small block Chevy 3.48 inch crank.

Several crank companies offer a 4.00 inch stroke crank for a 24x engine like your LS6. This will require different pistons with a shorter compression height to accommodate the longer stroke and it would be a good idea to replace the stock rods with stronger 4340 forged steel rod as well.

This will not be a budget conversion but it will bump the displacement from 346ci to 382ci. If we use something like 1.2 horsepower per cubic inch as a conservative estimate for a 382ci engine, this will make nearly 460 horsepower while a 346ci engine comes in at 415 hp. The biggest difference you will immediately feel is the torque. Again, assuming 1.2 lb.-ft. of torque per cubic inch that’s also 450 lb.-ft. of torque.

Summit Racing offers a 4.00 inch stroke 24x crank that will work with your existing Gen III block especially when matched up with a set of forged Pro LS pistons, and good connecting rods. We’d also highly recommend a set of Summit Racing GPX lateral gas port rings. Yes, they cost more but will also help with sealing the cylinder better which will make more power.

The LS6 employs a set of 243 casting heads that use a 65cc combustion chamber. Just adding a longer stroke will increase compression which is why the 9cc dished piston is necessary. With a zero deck, a 65cc chamber, and a 0.053 inch stock type MLS head gasket, the compression computes at a respectable 10.25:1.

To keep under budget you could build the 382ci short block with a decent cam of somewhere around 220 degrees at 0.050 that will maintain drivability and good low speed torque while still making decent power. You could retain the stock LS6 heads for the current time to keep the budget in line and upgrade with better heads and intake at a later date.

***

While certainly not a budget approach, you will be spending nearly as much just to rebuild the stock engine. With these far superior internal components you can rev the engine a little more freely without the fear of another failed piston or connecting rod.

LS6 Repair Parts List

- SUM-180LS400024X – Summit Racing Pro LS 4.00 inch stroke 24x crankshaft

- SUM-1109274030-8 – Summit Racing Pro LS forged dished pistons

- SUM-LS6125927 – Summit Racing Pro LS forged 6.125” connecting rods

- CLE-MS2199H – Clevite H-series main bearings

- CLE-CB-2199H – Clevite H-Series rod bearings

L92/L94 6.2 truck motors are the same basic thing as a LS3/L99 but much much cheaper. And the differences between them (cam/lifters/intake/oil pan) are things you would be changing out for a hot rod swap anyhow.