Spend enough time under the hoods of cars and trucks, and you’ll eventually run into a broken bolt or stud. Exhaust flange or manifold fasteners are the usual culprits, but broken fasteners can happen anywhere, at any time, as exposure to corrosive elements and constant heat cycling eventually weakens them.

If you’re lucky, some of the broken bolt will still be exposed and you can weld a nut to the remaining threads. The heat from welding helps break the corrosion loose, and the nut will provide a fresh grip point.

If you don’t have a welder, a torch or induction heater may expand and loosen material enough so locking pliers or a stud extractor can provide sufficient grip to remove it.

Using an open flame torch may not be suitable in heat-sensitive areas, such as locations near fuel lines or wiring. In these situations, an induction heater is more practical as it targets heat to a specific spot.

If the fastener is broken off flush or recessed, you will need to drill it, then twist it out with a bolt extractor.

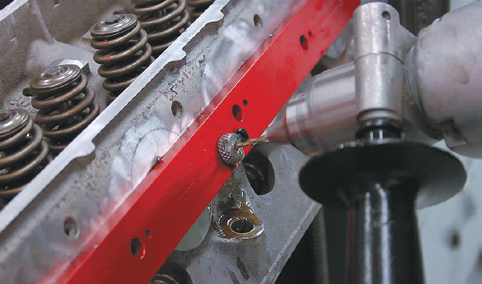

Drilling a hole into the dead center of the fastener is the most critical step in this process, yielding the most material to work with and minimizing thread damage if the fastener needs to be drilled out further. Using an engine/manifold drill template helps keep everything centered and straight.

Before drilling, center-punch the fastener and then drill a starter hole. Using a “center drill bit” is highly

recommended because they flex and walk less than a standard bit. Once the hole is started, you can try a

left-hand (counterclockwise) drill bit. The preferred method for a left-hand bit is holding firm pressure against the bolt and pulsing the drill in hopes the bit will snag the fastener and walk it out.

If that doesn’t work, an extractor is the next option. If the bolt refuses to come out, drilling to either rethread the hole or install a thread repair insert may be necessary.

In my shop we remove broken off bolts all the time with a TIG welder. One of our tricks is to use a 309 stainless steel welding. For some reason they seem to handle considerably more twisting torque than any other rod alloy we have tried. In the rare cases we are unable to weld the bolt out we use a carbide end mill and a drill guide or a milling machine to machine the bolt out.