In a motorsport defined by innovation, grit, and creativity, Matt Field stands out as a shining example of all three.

From his early days of drifting in California’s Bay Area while attending San Jose State University, to becoming a top-tier competitor in Formula Drift, Matt has always been known for pushing both himself and his cars beyond what many thought to be possible.

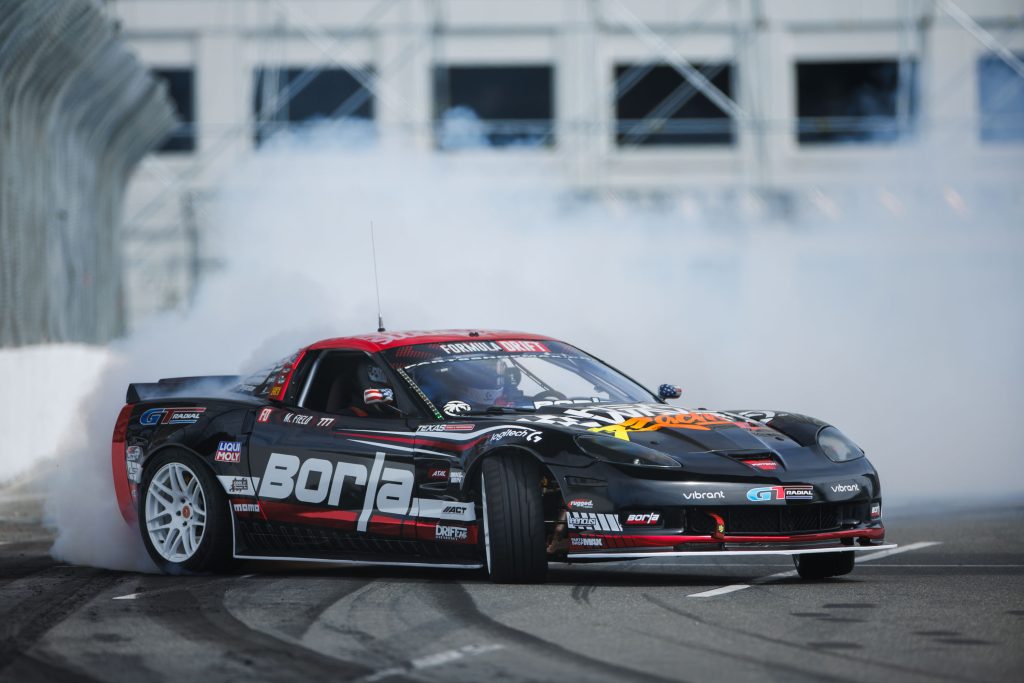

When most people think of drifting, they picture the cars that defined the sport’s early years: the Nissan 240SX, Mazda RX-7 FD, AE86 Toyota Corolla, and others. More recently—and thanks in large part to Matt’s contribution to the development of drifting-specific parts—C5 and C6 Corvettes have also become widely adopted. Despite their differences, these platforms share the same fundamental layout: a front or front-mid engine chassis with a manual transmission and rear-wheel drive.

Over the years, a few exotic mid-engine builds have appeared, such as the Lamborghini drift cars piloted by “Mad” Mike Whiddett and Daigo Saito. But until now, no one had transformed a C8 Corvette into a purpose-built drift machine.

Matt Field’s one-of-a-kind C8 changed that.

It debuted at SEMA 2024, and in 2025 it returned to the Borla booth—where we met Matt and heard firsthand what it took to create his manual transmission, LS-swapped C8 drift car.

Quarter Midget Racer to Professional Drifter

Matt’s introduction to motorsports came early, inspired by his father’s passion for competition. “From drag racing to desert racing, my dad did it all.” he said. Those childhood experiences laid the groundwork for his future as a professional driver. As he puts it, “My dad taught me basically everything I knew going into it. I was able to take those lessons and turn them into a profession.”

By just six years old, he found himself behind the wheel of a quarter midget, giving the competition a run for their money. At 16, it was already clear to him that drifting would be more than a hobby; it would be his life. By 19 he earned a Formula Drift license, making him one of the youngest drivers to ever compete in the series.

In 2010, Matt made his Formula Drift debut behind the wheel of a SR20DET-powered Nissan 240SX. Shortly after, he swapped in an LS engine for added power and reliability. In 2014, he became one of the first Formula Drift competitors with a car that utilized a rear-mounted radiator and produced over 700 horsepower.

After years of testing, development, and competition with LS-powered Nissans, Matt realized that it was time to move to a more capable chassis. Working closely with Parts Shop Max, a leading manufacturer of drifting-specific components, and the Formula Drift rule makers, he turned a flood-damaged C6 into a top-tier competition drift car—something that had not yet been done.

He unveiled his C6 at Formula Drift Long Beach in 2018, the very same venue where he first competed in the series eight years prior, cementing his status as a pioneer for the platform.

Why a C8 Corvette?

Like his first C6 competition car, the C8 demo car started its transformation at Matt’s shop, Drift Cave, as a flood-damaged car bought through an auction.

“We could see that water had gotten all the way up to the roof. When we got it, the engine and gearbox were full of seawater. This thing was basically a total loss—not something that could just be rebuilt—and that’s exactly what we needed,” he said.

With its lightweight aluminum spaceframe, dual-clutch transmission, and mid-engine layout, the C8 Corvette naturally drew attention throughout the drifting community and beyond. Matt’s modifications to this cutting-edge chassis offer a degree of grip and control that has rarely been seen within the world of drifting. As a result, it has opened the door to a whole new level of performance.

For Matt, building the C8 was about more than just doing something different. As with his C6 competition car, it was about pushing the limits of what’s possible and blazing a trail for others to follow.

Inside the Build: Technical Breakdown

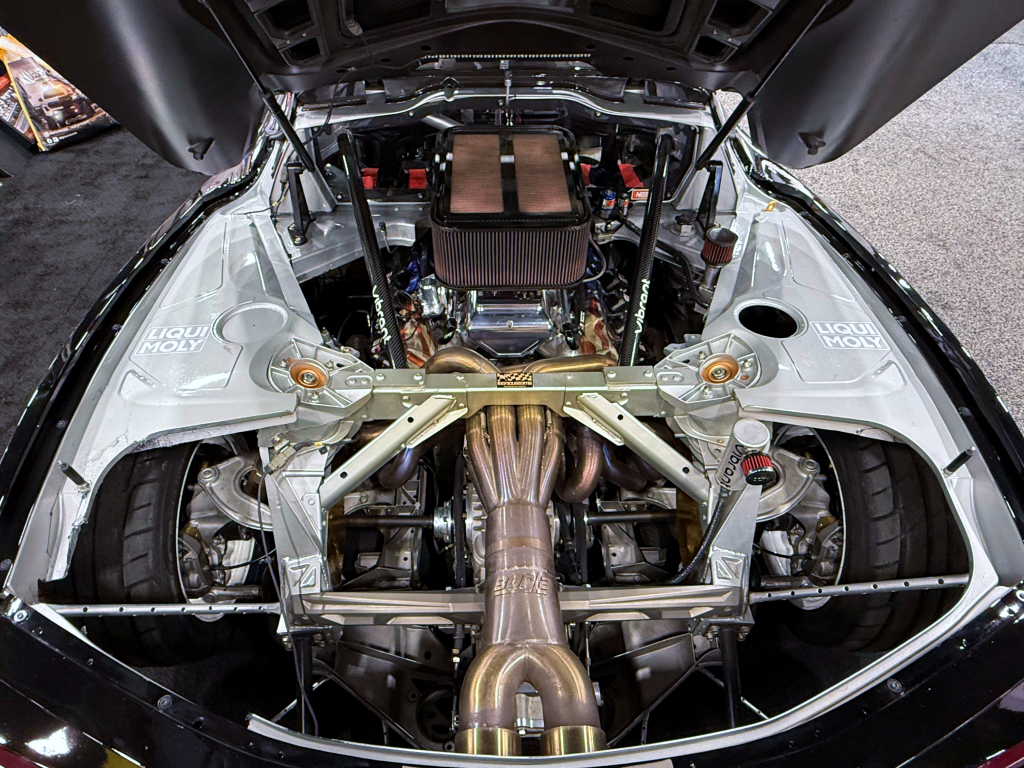

As you can imagine, Matt’s C8 is a highly modified, purpose-built race car, outfitted with countless bespoke components. From the one-off 10-gallon fuel cell mounted in what would ordinarily be a transmission tunnel, to the unique 8-to-1 headers, nearly every part has been engineered or customized for this application.

The result is a machine that stands as a testament to modern CAD design, fabrication, and innovation—exactly what the drifting community has come to expect from Matt Field and his competition vehicles.

Engine

Matt’s mid-engine C8 Corvette is powered by a 468ci Concept Performance LSR block—widely regarded as one of the strongest aluminum blocks on the market. Still LS-based at its core, this tall-deck block is heavily reinforced to ensure it can endure the punishment of living at redline. A raised, large-base-circle camshaft, supported by roller cam bearings, allows the engine to spin all the way past 9,000 rpm—an astonishing feat for a pushrod V8.

Airflow comes from dual 4500-series Wilson Manifolds throttle bodies, each moving 1,900 cfm into a custom intake manifold that feeds a pair of massive, fully custom SC2 Ford Cup–style cylinder heads—nearly two inches taller than standard LS heads.

A wild set of Borla rotary-fire 8-to-1 headers, built specifically for this car, deliver a sound reminiscent of a Formula 1 car while perfectly timing the exhaust pulses for optimal scavenging.

Spinning to 9,500 rpm and making 1,000 horsepower at the crank, this naturally aspirated engine shares only the oil pan gasket and rear main seal with its LS ancestors. Everything else is purpose-built. The result? An engine that performs under the harshest, high-revving conditions without compromise.

Oiling System

For anyone familiar with high-rpm engines, it’s no surprise this car relies on a dry sump oiling system to maintain proper lubrication. The four-stage scavenge pump, oil pan, and custom tank with an integrated oil-air separator—all from Armstrong Race Engineering—reliably keep oil exactly where it’s needed, even when the car is sliding sideways and the engine is screaming at 9,000 rpm.

Cooling System

Owing to its mid-engine design, Matt’s C8 features a fully custom, computer-designed, front-mounted PWR North America radiator equipped with two brushless Spal fans (unlike many front-engine race vehicles, which utilize rear-mounted cooling systems). As Matt describes it, “That keeps the thing that produces the heat as far away as possible from the thing that cools it.”

Like many other parts of this car, the radiator, mounting brackets, and ducting were all designed using CAD software and 3D scanning technology, allowing for a perfect fit on the first iteration.

Transmission & Differential

Of course, since this is a drift car, it has a manual transmission—something completely unique for a C8 Corvette, which are only sold with a dual-clutch automatic.

Matt’s C8 runs a Weddle S5 5-speed sequential transaxle with a separate reverse lever beside the main shifter—the same type of transmission commonly found in powerful sand cars (known for desert wheelies) and in Class 1 desert racing buggies.

This transmission, optimized for high-performance rear-engine applications, uses straight-cut gears with dog engagement, eliminating the synchronizers that often fail when production-style manual transmissions are used in competition. That design makes it especially well-suited to the harsh, shock-loaded drivetrain conditions common in drifting.

Since the transmission and differential are a single unit that’s mated directly to the engine in the rear of the car, there is no driveshaft. Custom made Driveshaft Shop axles send power directly to the rear wheels, delivering excellent power with fewer moving parts than traditional rear-wheel-drive cars.

Steering & Suspension

Staying true to tradition, Matt collaborated with Parts Shop Max to build a front suspension and steering package for the C8 Corvette, giving it the strength, articulation, and wide steering angle required for competitive drifting.

Because the C8 already incorporates GM’s most advanced suspension design, the rear end required very little alteration and naturally provides the geometry suited for this application. The only meaningful updates to the rear suspension are the addition of adjustable coilovers for added tuning capability, plus some custom machining to mount a secondary set of brake calipers for the handbrake system.

Wheels, Tires & Brakes

With an engine like the one in this car, it’s easy to see that braking will be a top priority. Thanks to Wilwood’s next-generation XRZero race calipers, Matt can get the braking he needs without the extra heft associated with most big brake kits.

To make sure he puts the power down and has enough grip to maintain control during high-speed drifts, Matt is running Forgestar F14 wheels wrapped in GT Radial tires.

Chassis

Because the C8 Corvette has an all-aluminum spaceframe, building a roll cage and attaching it securely to the chassis presented some unique challenges. After consulting with a fabricator at Pratt Miller Motorsports, Matt learned the installation would require a specialized adhesive and aircraft-grade rivets to secure anchor plates to the chassis where a roll cage could be mounted—a protocol not commonly used on platforms prevalent in drifting.

Aero & Bodywork

When the C8 debuted in 2019, its mid-engine layout and aggressive styling immediately drew comparisons to contemporary European supercars, and its overall design was seen as a huge departure from the classic “long hood/short deck” formula Corvette enthusiasts had come to expect over the previous seven generations. So you better believe Matt had his work cut out for him if he wanted his creation to stand out against what was already seen as the most radical version of the Corvette to ever roll out of Bowling Green. Appropriately, he found just what he was looking for in the home of drifting: Japan.

Known for producing some of the industry’s most extreme body kits and styling components, Japanese tuning shop Liberty Walk provided the widebody kit for Matt’s C8 build. Boasting aggressive front and rear bumpers, side diffusers, a huge rear wing, and (of course) those monstrous fender flares, the kit gives his Corvette the kind of eye-catching style drift cars are known for.

A carbon fiber hood, hatch, roof panel, and doors from Anderson Composites add an exotic flavor of their own while offering a significant reduction in weight when compared to the factory components. And it’s all wrapped in a striking livery, with exposed carbon fiber accents that ensure this C8 doesn’t just turn heads—it commands attention wherever it goes.

Interior

In true race car fashion, the interior of Matt’s C8 is strictly utilitarian, with a few functional aesthetic touches.

The dash is a carbon fiber unit from Anderson Composites—the same one he’s been running in his C6 for years.

The list of C6 components doesn’t stop there. Matt also cut and retrofitted the carbon fiber door cards from his C6, creating a lightweight, visually clean design that maximizes interior space.

To the left of the shift levers, the cockpit features a rally–inspired handbrake lever with an integrated manual line lock, used in place of a traditional parking brake. A Momo steering wheel, bucket seats, and 5-point harnesses keep Matt locked in for maximum control no matter how fast and hard he hits the corners.

An AiM Sports digital display and push-button style switch panel are mounted to the carbon fiber dash in conjunction with AIM PDM32 and PDM08 power distribution modules. Below the switch panel lives a Rugged Radios two-way communication system with a built-in intercom—allowing open communication within the cockpit when Matt takes fans for rides during exhibitions.

Yes, that’s correct: if you play your cards right, you just might get a ride in this one-of-a-kind drift car!

Final Thoughts

While listening to Matt Field describe the process of designing and building his latest demo car, one thing became clear: his C8 Corvette is more than an awe-inspiring feat of engineering—it’s a glimpse into the future of drifting and a reflection of what’s possible when technology meets innovation.

And of course, as Matt says, “It rips!”

Want to watch Matt bring this beast to life? Check out the full build series on his YouTube channel, where he has 50 videos documenting each step of the process, including a test day at Thunderhill Raceway!

Comments