If you work on engines a lot, you’ve probably removed a valve spring or two in your time. The process isn’t difficult when you use the right valve spring compressor. For budding engine builders ready to tackle their first valve spring swap, we thought we’d run through the various types of spring compressors for pushrod V8 engines and offer our two cents on the ones we like.

Story Overview

- Lever-style valve spring compressors are ideal for engines with light-duty valve springs

- Over-center valve spring compressors center the tool’s fork over the spring so you can remove the valve locks without having to hold the lever down

- Off-engine spring compressors are used for cylinder heads on a work bench, which is usually the most efficient way to assemble a head

- To remove valve springs with the cylinder heads on the engine, you must feed compressed air into the cylinder to prevent the valve from dropping

On-Engine Valve Spring Compressors

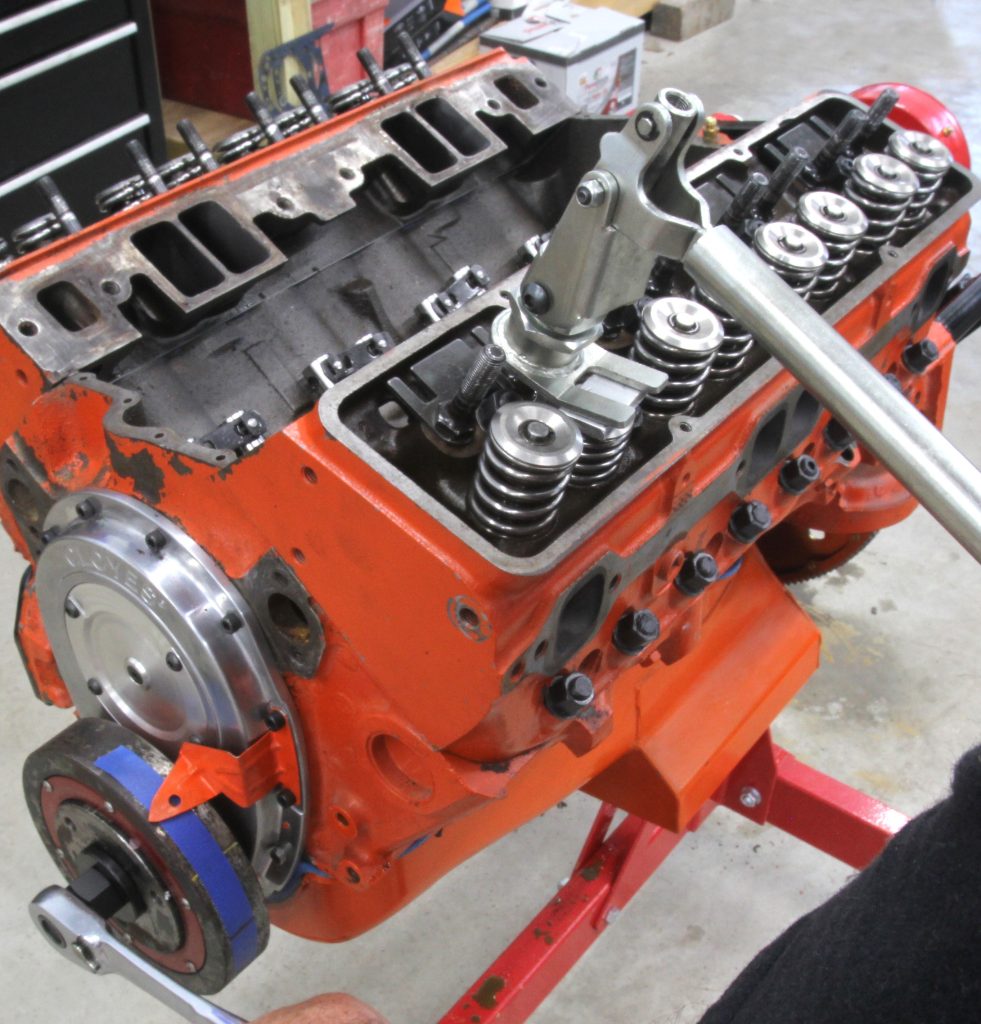

On-engine spring compressors are designed to work with the cylinder heads bolted to the engine. Most will also work on cylinder heads sitting on the bench.

The lever style compressor is the simplest type and is likely the oldest. Most are designed for cylinder heads with either 3/8- or 7/16-inch diameter rocker arm studs. The tool uses leverage and arm strength to compress the spring and retainer so you can pull the valve locks. You then release the lever tension to remove the spring.

The lever spring compressor works fine on engines with flat tappet lifters and OEM-style, light-duty valve springs. But for something like a high-RPM big block Chevy with dual springs rated at 400 pounds of load on the seat, the tool won’t hack it unless you have biceps the size of an average man’s thighs.

The over-center spring compressor is another version of the lever type. Designed for engines with individual stud-mounted rockers, it’s useful for quick spring changes with the engine in the car as long as there is room for the lever arm to travel through its arc.

The over-center compressor mounts on the rocker stud after removing the rocker arm and pushrod. You position the tool over valve spring retainer and pull down on the lever to compress the spring. Then you can remove the valve locks. An eccentric cam keeps the spring compressed without having to apply pressure on the lever. We don’t completely trust that feature, so we always place our body over the lever to keep it in place when removing or installing the locks.

Another on-engine valve spring compressor that works very well for us comes from Trick Flow. Designed for GM LS cathedral port cylinder heads, the tool attaches to the head using the rocker pedestal bolt holes. It compresses two springs per cylinder by turning a threaded stud. There are single-spring versions of the Trick Flow LS spring compressor that use a long threaded shaft that can handle stiff valve springs.

Single-spring compressors fit in tight spots where there’s not enough room for larger lever-style compressors. You can use them with cylinder heads on or off the engine. An older design uses small jaws that attach to the lower portion of the spring. You turn the top wheel to compress the spring and release the valve locks.

Off-Engine Valve Spring Compressors

Off-engine spring compressors are used for cylinder heads on a bench, which is usually the most efficient way to work on them. The compressors are generally (but not exclusively) shaped like a C-clamp. One end fits over the valve spring and the other presses against the valve face in the combustion chamber.

Many years ago we purchased an early version of a large C-clamp spring compressor. It was made of stamped steel and used a short lever arm to compress the valve spring. It was cumbersome to use, and the cloved hoof style retainer adapter was flimsy and would bend when used on big valve springs. You also had to hold the lever handle down with force to prevent the spring from pushing back up as you were removing or installing the locks. This often required three hands.

Newer C-clamp spring compressors are much better designed. Most have a beefy aluminum body with a large threaded rod. They are easy to use and will never “let go” of the spring once compressed—and only two hands are required.

Summit Racing has a version of this spring compressor with a couple of neat features. The Pro Billet compressor has a handle on each end to adjust the tool to fit a wide variety of cylinder heads. The handles have long- and short-throw positions for either speed or additional leverage, which is also nice.

The retainer side of the Pro Billet compressor has a tapered seat to accommodate retainers ranging from 0.850 to 1.650 inches in diameter. The pitch of the threaded shaft creates enough leverage to compress springs with loads of up to 1,000 pounds. The standard spring cage fits most small and big block V8 cylinder heads, and has a bearing style end to reduce friction.

We tried the Pro Billet spring compressor on a couple of different cylinder heads and found it made the job of changing springs less tedious and a whole lot less dangerous. If you’ve ever had one of those older lever style, off-engine spring compressors accidentally let go, you know it’s not something you want to experience a second time.

Hopefully, we’ve offered enough information so you can choose the valve spring compressor that best fits your needs. We’ve included links to a selection of tools available at Summit Racing.

As we learned decades ago, investing in a better tool will pay off many times over by allowing you to complete a job quicker and easier than a cheap tool that fights you the entire time.

On-Engine Valve Spring Compressors

Summit Racing Lever-Style Valve Spring Compressor SUM-906784

Summit Racing Valve Spring Compressor for GM Gen V LT Engines SUM-906789

Trick Flow Valve Spring Compressor for GM LS Cathedral Port Heads TFS-90306

Trick Flow Valve Spring Compressor for GM LS Rectangular Port Heads TFS-90307

LSM Racing Valve Spring Compressor, fits 7/16″rocker arm stud LSM-SC-800

OTC Single Valve Spring Compressor, 2-jaw style OTC-4573

Off-Engine Valve Spring Compressors

Summit Racing Pro Billet Valve Spring Compressor SUM-VSCPRO

Summit Racing Lever Style Valve Spring Compressor SUM-906788

LSM Heavy-Duty Valve Spring Compressor LSM-SC-2000

Proform Heavy-Duty Valve Spring Compressor PRO-66764

Comments