Talk about turning lemons into lemonade? Ford knows this one firsthand and it has a long history of turning misfortune into triumph. Ford’s very beginnings were marked with failure—then, with good backing and manufacturing support, Mr. Ford hit pay dirt in 1903 with the founding of Ford Motor Company. Ford enjoyed great success in its beginnings with the Model A and T early in the 20th century—putting the average Joe behind the wheel.

It can safely be said that Ford put the world on wheels.

Henry Ford became decidedly complacent amid his successes and there wasn’t much new from Ford throughout the 1920s. In fact, Mr. Ford didn’t see any real need for change. However, Ford soon found itself behind the competition.

Mr. Ford took the bold step of shutting down the company down to design an all-new Ford for 1932—the Ford V8—which became legendary for its power and smoothness. Ford’s decision to shut down paid off with incredible sales numbers in the years to follow.

During World War II, Ford and the auto industry in general did very well supporting the war effort. There was plenty of work to go around. Ford built war machines like the B-24 Liberator bomber, battle tanks, Jeeps, you name it. When the War ended, Ford found itself in deep trouble.

Its old school methods were way behind the curve.

Henry Ford II was called out of the Navy to run the company and save Ford. He assembled a group of brainiacs—military strategists—known as the “Whiz Kids” who reinvented the way Ford did business. It hired great designers and engineers who did incredible things. One of those great things was the all-new 1949 Ford, which saved the company. Ford prospered throughout the 1950s and ‘60s with new and exciting products like the two-seat Thunderbirds and the overhead valve Ford Y-Block V8.

Then came Edsel—the name and the car line for which there was no market.

Edsel was an unfortunate miscalculation by Ford’s marketing people. The car was handsome, yet at the same time, ugly. Perhaps more importantly, it had a host of mechanical issues that made it unreliable. Because there were no buyers, Ford couldn’t sell them.

After three miserable years of one Edsel failure after another, Ford made the difficult decision to scrap Edsel—the carline and the division—in 1960. Ford hung its head low in the years following Edsel. It was an embarrassing mistake hard to live down—especially in Detroit and certainly in America. Consumers who lived the era will never forget Edsel—a name synonymous with failure.

Ford entered the 1960s with a vengeance. Robert McNamara, a practical thinker and father of the economical and highly successful Ford Falcon, left the company to join the Kennedy Administration as Secretary of Defense. This opened the door for a bright young Ford executive, Lee Iacocca, to infuse adrenaline into the Ford Division with the “Total Performance” program. Engines grew larger and more powerful. Stodgy boring sedans became fastbacks and convertibles. The stage was set for even greater things—like Falcon Sprint, Galaxie XL, and Mustang.

Iacocca spearheaded the “Sporty Ford Car Project” known as T-5. Anxious for viable solutions, Iacocca staged a competition across the three design studios—Ford, Lincoln-Mercury, and Advanced Design. On a warm August morning in 1962, the three studios rolled out their ideas in clay in the Ford Design courtyard. One entry was head and shoulders above the rest—the striking short-deck/long nose “Cougar” created by designers Gale Halderman, Joseph Oros, and Dave Ash.

Oros wanted the Cougar name. Mr. Ford wanted Torino. After a bit of a scandal with Mr. Ford being involved in an extramarital affair in Italy, the Torino name was dropped at the eleventh hour and there was a frantic search for a new name. Ford’s marketing people decided on Mustang.

Where Ford had overestimated Edsel sales and came away empty handed, Mustang was underestimated at 100,000 units in its first year. Ford wound up selling nearly 600,000 Mustangs its first 18-month model year. It couldn’t build Mustangs fast enough and wound up bringing three plants online to build them. America’s Original Pony Car was a phenomenal success.

This leads us to where Mustang went in the years to follow. Thanks to Carroll Shelby and his magic touch with the Cobra and GT350, Ford’s sporty Mustang hit the SCCA Trans Am circuit, spanking Corvettes on racetracks wherever it was raced. Mustang performed very well its first two years out. When Chevrolet arrived with the Camaro in 1967 with its high-revving 302 inch Z/28 engine, it closed the gap—passing Mustang up. Ford needed a plan.

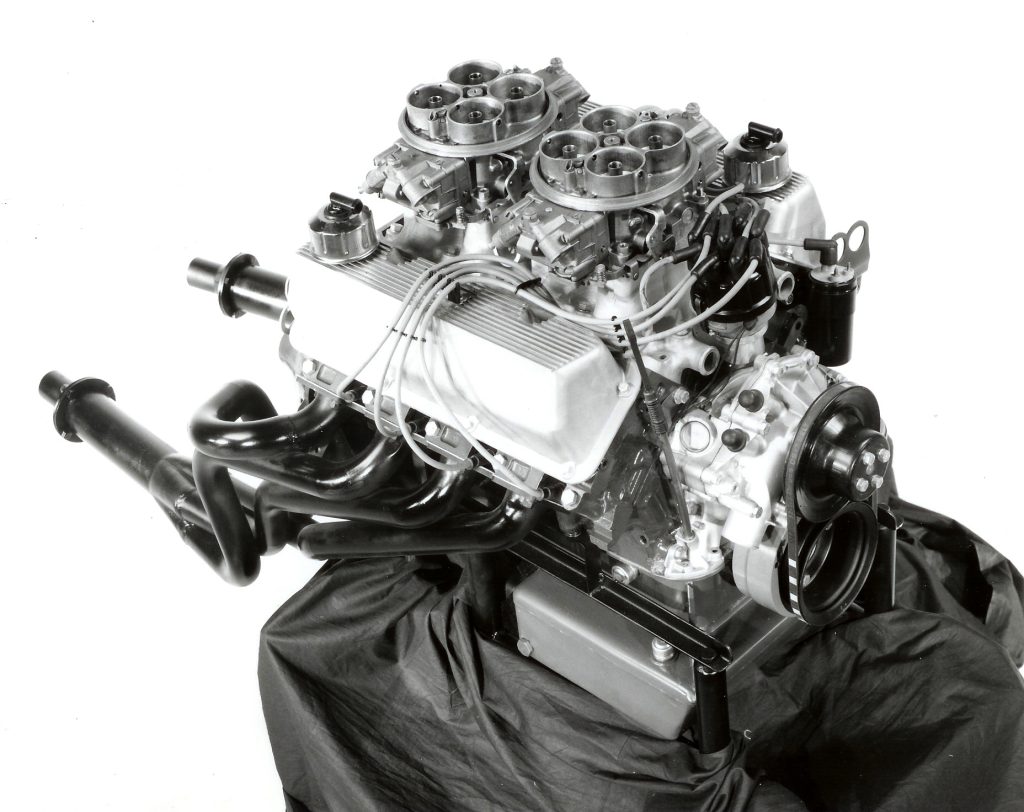

Ford’s answer to the Z-28 was a high-revving 302ci V-8 of its own—the ill-fated “Tunnel Port” of 1968.

The Tunnel Port had enormous potential, however, it made peak horsepower at well above 8,000 rpm. Tunnel Ports were pushed to their limits and beyond resulting in catastrophic engine failures—too many of them. They could blaze tracks all day long at 7,500 rpm. They could not survive at 8,500 rpm chasing Camaros.

Automotive historian and author, Eric English, said this about the Tunnel Port in Hot Rod Magazine, “The Tunnel Port was an extremely high-rpm engine, lacking bottom-end grunt. Hank Lenox, lead engineer for the project, told HOT ROD in a recent interview, ‘At the time, my bosses at Ford felt horsepower won races, so the task was to create a head that made a big peak number. Even then I believed it was the wrong approach since road racing requires a broad powerband and plenty of torque for coming out of the corners. The Tunnel Port worked well in a narrow, high-rpm range—actually more suited to the kind of rpm found in oval-track racing. I wasn’t surprised when the Trans-Am effort struggled.’”

English went on to report, “Lenox should know, for in addition to the 302 Tunnel Port program, he worked in Ford’s in-house Indy and LeMans programs, designed the original GT40 head that the Trans-Am teams used a derivative of in 1967, and also contributed to the Gurney-Weslake heads that helped John Wyer’s GT40s win LeMans in ’68 and ’69.”

“Chuck Cantwell was the team engineer for Ford’s only factory Trans-Am team in 1968—the Shelby Racing Company—and explained many of the same issues about the nature of the 302 Tunnel Port. Cantwell says that 8,500-rpm shift points were commonplace, with occasional 9,000-rpm blasts—at least 1,000 to 1,500 revs higher than in 1967, and clearly exploring the limits of the reciprocating assembly, the GT40 four-bolt block, the valvetrain, and the oiling system,” English reported, “Still, there was a flash of brilliance for the Tunnel Port, and the street scene surely would have devoured something better than Ford’s only production offerings at the time—the pedestrian 289/302 head castings with their diminutive 1.78/1.45 valves. Too bad the program didn’t work as planned.”

“The racing debut for the 302 Tunnel Port could hardly have been on a bigger stage: the ’68 24 Hours of Daytona. Cantwell recounts how the Shelby team was scrambling to prepare the new engine and cars for the event ‘right down to the wire.’ Out of the box, the Shelby guys got it right, as Jerry Titus and Ronnie Bucknum drove their red No. 1 Mustang coupe to the Trans-Am victory, and Fourth overall behind a trifecta of prototype Porsches,” English commented, “Hour upon hour of running Daytona’s blend of road course and high-bank would have seemed the ultimate shakedown for the Tunnel Port, and an endorsement of its durability. Says Cantwell, ‘We ran the first two-thirds of the race pretty hard, but fortunately were able to take it a little easier for the last third as our competition had fallen far behind. It’s a good thing, too, as I don’t think the car had much left in it.’” The 302 Tunnel Port had a good first time out, however, it wouldn’t last.

During a recent conversation with Bill Barr, chief engineer for the BOSS 302 development program, much was learned about how Ford arrived at the Tunnel Port, which was a colossal failure—and how Ford succeeded with the BOSS 302. Barr is one of very few Ford engineers left who can talk about his remarkable career with Ford Motor Company. Barr worked on the overhead cam Indy Ford V8 program in the early 1960s, and later the 428 Cobra Jet. It seemed logical to assign him to the struggling 302 Tunnel Port project.

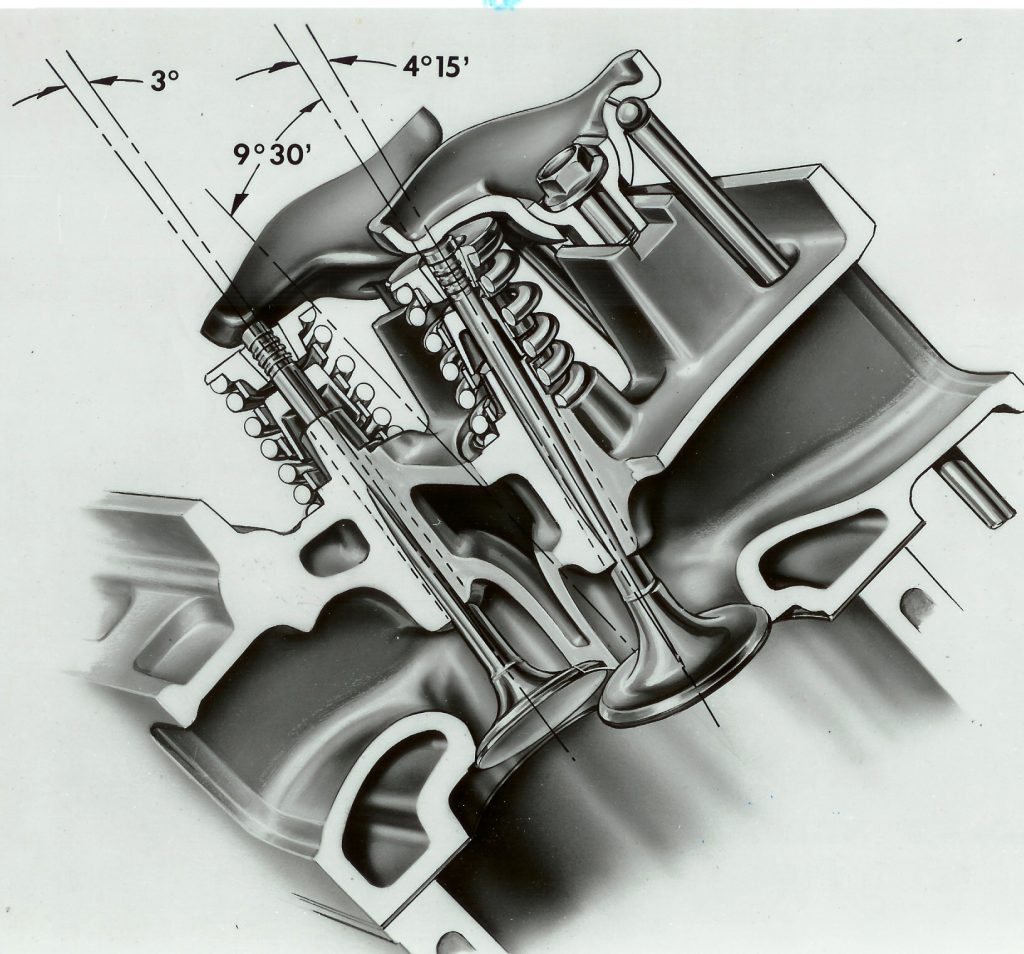

Barr had a lot to say about Ford’s engine development programs during the 1960s. When word rolled back to Dearborn describing the trouble Ford’s 302 Tunnel Port was in on the racetrack, Barr needed quick answers before the beginning of the 1969 SCCA Trans Am season. Barr was aware of the 335 Series engine (351C) program going on at Ford’s Advanced Engines department. He went over there for a look at what was going to be the new Ford “Cleveland” small block displacing 351ci.

He candidly told me the 351C engine was a terrible idea and that the only good thing about the Cleveland was its cylinder heads.

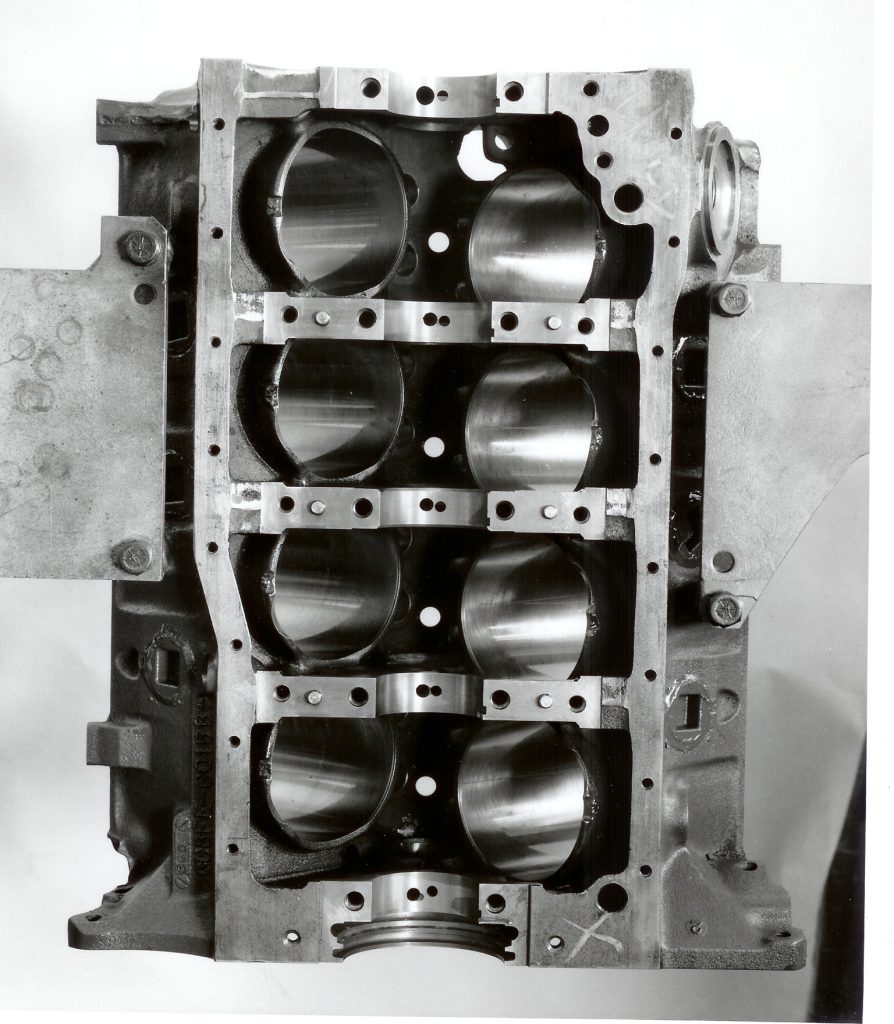

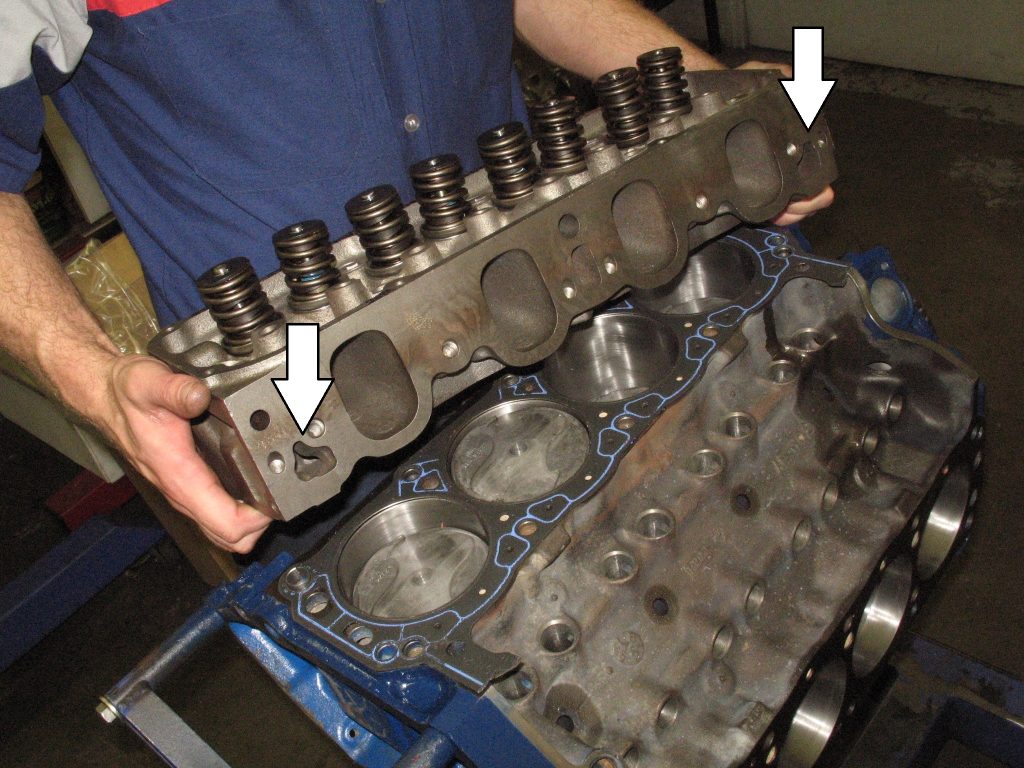

The 351C tipped the scales 100 pounds heavier than the 289/302, had a horrid oiling system, and bottom end architecture that was not up to par. Bill measured bore spacing and bolt patterns of both block and heads and realized they were identical to the 289/302/351W.

With more research, he learned he could modify the Cleveland head to work with the “wet” 289/302 intake manifold (the 351 Cleveland intake manifold does not carry coolant) and block. During extensive dyno testing with the Cleveland 4V head, he learned they could make peak horsepower at 7,500 rpm and compete successfully with Camaro.

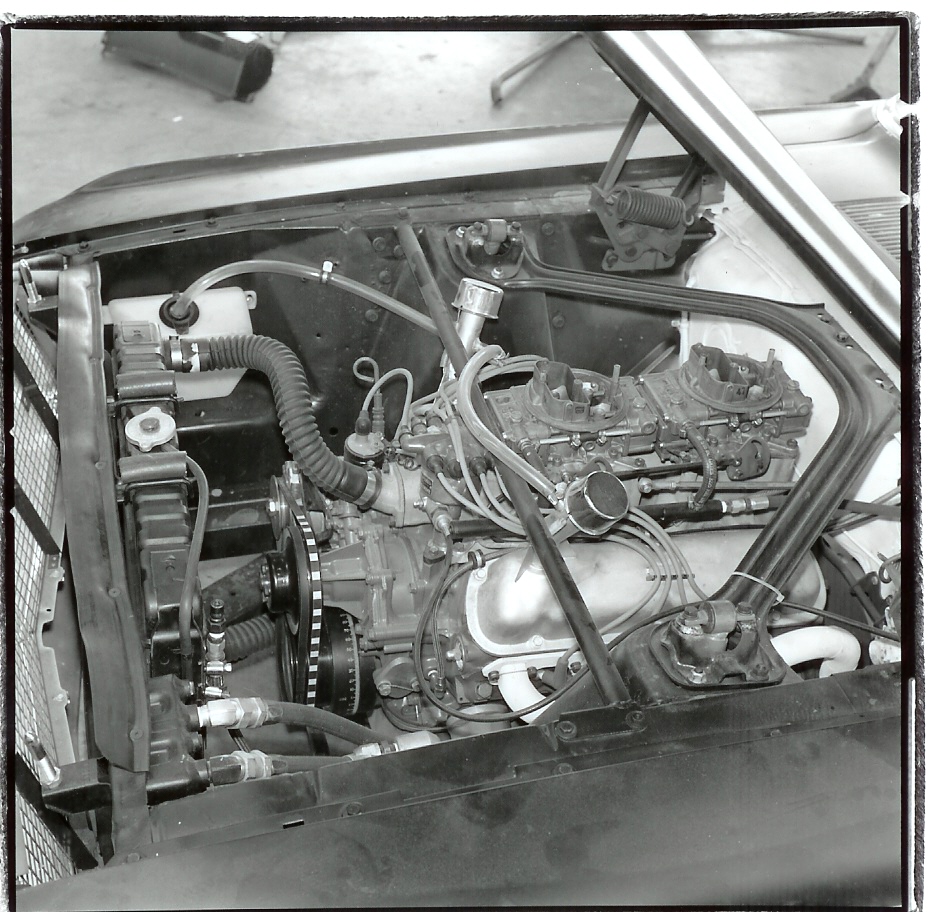

Of course, this is an oversimplification of his research program, which became quite involved. Ford could ill afford another bad season. The BOSS 302 development team managed to get a Z/28 Camaro and put it through some thrashing on the dyno. The number to beat for Ford was the Z/28’s advertised 290 horsepower. In Ford’s dynamometer laboratory, Barr was able to get an easy 290 horsepower from the Cleveland head 302. In fact, test mules went beyond 300 horsepower. Despite their successes, there were setbacks. They knew they had a piston problem, which was ultimately resolved by the supplier—TRW.

The good news for the BOSS development team was the Tunnel Ports brute block architecture with its thick main webs, decks, and cylinder walls. No further development of the block was necessary. Once they got heads and pistons dialed in, they were ready to real world test the BOSS 302 engine. Development went quite well with the next step being adapting a race engine to street use and homologation requirements imposed by the SCCA.

The BOSS 302 Mustang entered mass production in April of 1969 as a mid-year attention getter. The message it sent was Ford was in racing to stay. It had a couple of good solid years before pulling the plug on racing. Ford got out of racing in the 1970s with higher insurance rates for muscle car buyers and tougher safety and emission standards.

The factory muscle car was all but dead.

Ford planned the BOSS 302 through 1971, which proved to be too expensive due to manufacturing costs for the limited production BOSS 302 engine. Ford went to work weaving performance nuances into the 351C-4V engine, which made it worthy of the BOSS name. There would be a BOSS 351 Mustang for 1971. The BOSS 302 was euthanized.

I’m so glad to see Bill Barr getting the credit he deserves for the Boss 302 program. I am the current caretaker of Bill’s 1970 Boss 302 SCCA race car and I’ve had many conversations with him. He is a wonderful man with a fantastic memory. Keep up the good work!

I have an Original 1970 302 Boss Block, New, Never Used. Anyone interested ?

Send me an E-mail. Thanks

hi i have a 2×4 tunnel ram intake with 2 Holeys off a boss 302 with no id marking need help to id it be for i put it up for sale can you help thanks