I’ve heard that gas ports drilled into pistons for race engines could also be used for hot street engines but that they don’t work very well because eventually the ports become clogged with carbon and quit functioning. I’ve also heard that these ports accelerate ring wear to the extent that the engine needs new rings after only maybe 5,000 miles.

So if that’s the case, then wouldn’t those gas ported top rings that I’ve heard about wear just as quickly? These sound like they would work for a race engine but would just wear out a street engine just as quickly. Thanks for your time.

T.F.

I’ve heard two race engine builders talk about street engines running gas-ported pistons and they both said that the gas ported rings wear out rather quickly but I never really thought about it much because my attention was always on engines intended for the street.

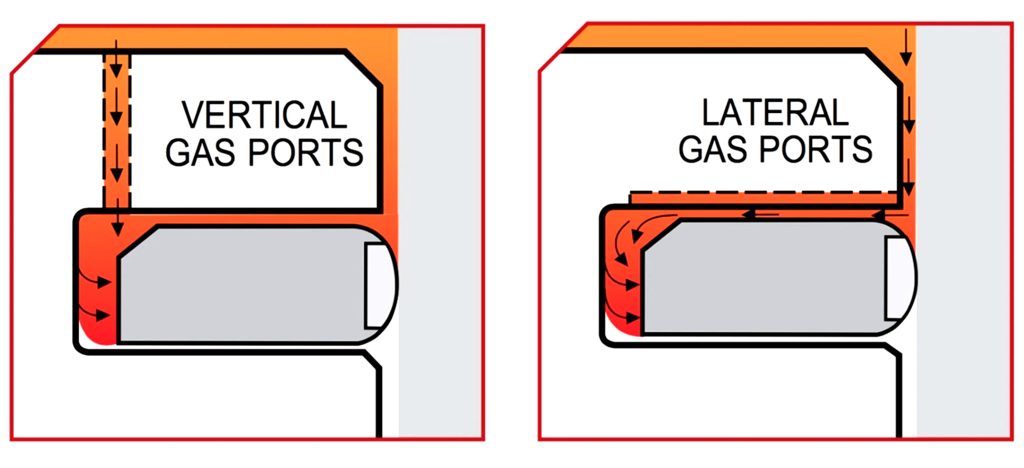

The gas porting technique is to drill 8 holes through the top of the piston to intersect with the inside of the top ring land. The idea is to direct cylinder pressure behind the rings to improve ring seal. The problem with this idea on the street is that eventually carbon will build up in these rather small 0.043 inch holes and prevent the cylinder pressure from doing its job.

Some high performance forged pistons have come with lateral gas port holes drilled to intersect the top of the top ring land—assuming sufficient room between this lateral gas port and the top of the piston. Generally there are four to six of these holes with the intent to direct combustion pressure behind the top ring.

We spoke with Lake Speed, Jr. of Total Seal to get his take on this question of gas porting and also for a description of Total Seal’s new gas ported top rings. Lake said that detergents in the oil do not do as great a job of cleaning deposits in aluminum pistons as they do against iron or steel. Plus, while the top and second piston rings continue to turn in the ring groove, the drilled holes concentrate the pressure in the same location which can increase bore wear in these spots.

In describing the Total Seal gas ported rings, Lake says they have 15 gas ports cut into the top of the ring and since the ring is continually rotating inside the groove, there is no set concentration of pressure against the cylinder wall but instead offering an even distribution of pressure across the entire ring.

As a personal reference, Lake said he is currently running a set of the lateral gas ported top rings in his daily driver Porsche which now has over 10,000 miles on the rings. He said the factory engine uses an oil separator system that maintains a vacuum inside the crankcase.

This offers a great opportunity to create a constant check on ring seal because if the ring seal begins to deteriorate, this would allow more blow-by past the rings and the vacuum in the crankcase would drop or turn into pressure. Lake reports that after 10,000 miles the engine is still pulling the same vacuum in the pan as it did just after the rings were installed.

Much of this comes down to how trick you want to make your next street engine. The Total Seal gas ported rings are a bit more than twice the cost of an otherwise conventional Total Seal ring set for a 4.030 inch moly top 1/16, 1/16, 3/16 inch ring set. From testing we’ve seen, there can be a double-digit (meaning in the teens) horsepower improvement on even a mild a 400 hp street small block Chevy. At this point it then becomes a question of power return versus the investment. Overall there does not appear to be a durability tradeoff.

Thanks for the article, I’m just getting into the final stages of a stock bore large journal 327. I had total seal gas ported ring installed. Sounds like I made a good choice.

In general gas porting has not increased measurable bore wear rates in my experience. I agree that the top drilled ports are more prone to plug with carbon, particularly if fuel control, EGR operation (if equipped) or oil control isn’t well thought out and that if you’ve got a carbon generation problem that carbon may be abrasive enough to increase bore wear but I’m not confident that we should lay the blame on the porting in that instance. Given the side and back clearance of a normal ring in the groove, cylinder pressure will always act to push the ring out into the cylinder wall as compression pressure builds with piston rise. All gas porting does is “activate” the ring earlier, increasing ring to wall pressure earlier in piston rise. Instead of the rising pressure having to thread its way around and behind the ring the porting gives it a more direct path to the gap between the inside of the ring groove and the backside of the ring more quickly eliminating any differential pressure. Porting does increase measured compression pressure as recorded on a compression tester just as a zero gap ring does. I’ve seen pressures increase by as much as 20 pounds on zero gaps and half that on ported standard top rings. I’ve got almost 71 laps around the sun and we used to do a cylinder leak down on every engine tune up back in the bad old days. It was common to see street engines come in at 40-60% leakage and down on compression by 50 pounds that ran just fine but were down on power and were only a tiny bit high on blowby. The reason for that was that under dynamic conditions the rings would push out into the cylinder walls and seal well enough that the vehicle was perfectly serviceable, albeit notably a bit “lazy” when driven. Narrow, low tension, low radial wall thickness rings like porting since it helps the ring seal up better earlier in the compression upstroke.

It’s also helpful to remember that while we call the second ring a compression ring it’s really a fine oil control ring, with what we call the oil ring functioning as a gross oil control ring. If you see any color at all below your top ring on the land between the top and second you’ve got a problem starting.

And that is just one man’s opinion.

Best to all,

Greg

hey Jeff. Its Steve from Bob Lambecks in Northridge ca. hows Iowa??? burrrr. lol. I am building a new 350 gen 1 sbc for my procharged buick skylark. I’m upping everything inside forged crank, rods, pistons ect. which should I use for the street and occasional open track time at willow. 4032 or 2618 alloy? I have been looking at Wiseco pts508a3 pro true street pistons 4032 w 1/16,1/16, 3/16 rings or their RED0008x3 2816 pistons with 1.2, 1.2 ,3 mm ring pack. I also talked to kevin Studaker at Total seal and he recommended their cs3690 35 Advanced Profiling Ring. steel top with chromium nitride coating, second cast iron and 20+ lb conventional oil rings. I plan on using a Howards Boost retrofit hyd roller cam 525-535 lift and 225-235 dur @ .050 max rpm 6400. AFR as cast enforcer 200cc intake runner heads with iconel exh valves 64 cc, 9.5-1 comp. I plan to run around town with 8 lbs of boost and on the track change the blower pulley and run 10-12 lbs boost. whoo! hoo! sounds good on paper. lol. would gas ported rings be a good Idea for my build? what are your thoughts?