I have a used 5.3L LS truck engine that I’d like to swap into an earlier Chevy pickup. The engine was running when it was pulled out of a wrecked 2003 Silverado. The engine has almost 200,000 miles on it. I’ve heard that the cylinder walls can be pretty good even after this many miles. Would it be okay to just put new rings and bearings in this engine and put it back together?

M.C.

One of the cool things about the LS family of engines (and especially the truck engines) is that they are incredibly durable. Like you, we’ve pulled several of these early Gen. III LS truck engines and used them for magazine stories. Your engine sounds like it did not spend any time sitting around getting water in the bores or anything like that, so likely it is in pretty good shape internally.

A big reason why these engines are so durable has to do with factors like material use, construction, fuel injection, and the quality of current engine oil.

The cast iron LS blocks are considerably harder than the soft cast iron used in previous generation engines from the 1960 through the 1980s. Plus, fuel injection more closely controls the fuel so the cylinders are not washed down with raw fuel during cold starts from very rich mixtures common with carbureted engines. This maintains a higher quality of oil in the engine that does not contain unburned fuel, which does not work well as a lubricant.

Plus, engine oil today is a much higher quality lubricant than in past generations. True, the levels of zinc and phosphate (ZDDP) are lower, but with roller lifters, the levels are still good enough to maintain proper wear patterns.

So, What Should You Do to Your Cylinders?

To get to your question, we asked Lake Speed, Jr. at Total Seal his opinion on this technique. Obviously, the best approach would be to bore and torque plate hone the engine and use a quality piston and ring combination.

But acknowledging that not everyone has the budget that allows for a set of forged pistons and expensive piston rings, there are some steps you can take. We will assume that you’ve removed the cylinder heads and the bores are smooth with no obvious ridge at the top of the cylinder. With older engines this was a common maximum wear point.

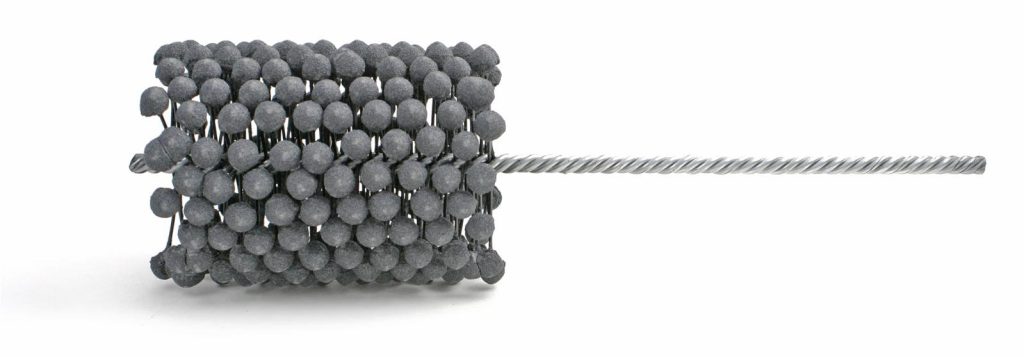

So with a decent looking bore, Lake Speed says that a typical brush hone can be used to create a fresh crosshatch pattern on the cylinder walls. Speed recommended a 320 grit hone for this application and he said that this is only good for a typical ring package using a moly top and iron second ring.

He warned that this will not work with the harder PVD-coated steel rings that are often used for a supercharged or turbocharged applications. The steel rings need a much deeper valley to hold sufficient oil to lubricate these harder rings and the flex hone can’t create that depth of cut. Steel rings would require a more professional honing approach.

But for a typical moly ring that you would use on the street for a mild normally aspirated engine, Speed said that a 320 grit Flex Hone would be sufficient. We looked into Flex Hones from Brush Research Manufacturing (BRM) and found the appropriate brush that would fit the 5.3L’s 3.78 inch bore size with a silicon carbide honing material in a 320 grit. We’ve listed the part numbers below in the Parts List.

Cylinder Honing Techniques

These brushes do not come with instructions but we did find a few videos online from BRM that reveal the procedure. First, you must completely disassemble the engine which includes removing the crankshaft. This is mainly because you want full travel of the brushes and the residue left behind is obviously highly abrasive and will need to be completely cleaned before reassembly.

BRM recommends using a half inch drill motor with a spindle speed of between 500 and 800 rpm. Never exceed 1,200 rpm. Enter the cylinder with the brush already rotating. BRM recommends 60 to 120 strokes per minute (which is roughly one to two strokes per second) to establish a proper crosshatch pattern. Average honing time is 10 to 20 seconds but use the least amount of time to establish a proper honing pattern.

BRM says to use a honing oil to lubricate the process and to wash the abrasive away from the surface. BRM sells its own honing oil, but light engine or cutting oil can be substituted.

With these recommendations, you can see that it won’t take long to hone each of the eight cylinders. You will probably spend more time cleaning the cylinder walls and the rest of the block rather than honing.

BRM also recommends using a cleaning brush along with hot soapy water to fully clean the cylinder walls. We’ve found that after honing from a professional shop that we will spend 30 to 40 minutes cleaning the cylinder walls with a combination of white paper towels coated with Marvel Mystery Oil. We’ve found this seems to work the best for removing that tough honing residue. Our process is to clean each cylinder with a fresh paper towel until the dark grey residue no longer appears on the white paper towel. There are probably other techniques that also work, but this is what we’ve found works for our engines.

It’s also important to thoroughly clean and inspect the pistons for possible damage before re-using them. It does little good to use new rings with pistons that have damaged or worn ring lands. While most people regard ring seal as it relates to the cylinder wall, the ring also seals to the piston ring land as well. If the ring lands are worn, this will reduce the effective ring seal so look at the old pistons carefully.

Piston Ring (& Break-In) Recommendations

A ring set recommendation for your engine would be a set of Classic Street Total Seal replacement rings for the 1.5mm top, 1.5mm second, and 3.0mm oil rings. This set includes non-file fit, ductile iron moly top ring with a cast iron second and standard tension oil ring set. These are not file-fit rings although those are also available. Of course there are other companies offering replacement style ring sets such as those from Federal-Mogul, Hastings, Mahle, and others.

One warning when breaking in the new rings is to not allow the engine to idle for a long period right after startup. To fully seat the rings, you should put a load to the engine as soon as possible. Start it and allow it to reach operating temperature in the vehicle and then drive it so cylinder pressure can load the rings against the cylinder wall to seat them.

A run-in stand is not recommended since this does not place a load against the engine. If run with no load for 20 to 30 minutes, the rings will glaze the cylinder wall and not establish a proper seal—then you will have to do the job all over again.

This is why an aggressive break-in period is so important.

Cylinder Honing Parts List

- BRM Flex Hone, 4.00” Bore – BRH-GBD40032

- BRM Cylinder Wash Brush – BRH-10A4

- BRM Honing Oil, 1 Quart – BRH-FHQ

- Total Seal Classic Ring Set – TSR-CR8794

Finished installing Blueprint 350 naturally aspirated Holley 650 in a 1956 Chevy wagon motor purchased new but damaged from summit. Busted distributor on new complete long block it has original tank . Do not think it is vented will run grey for about 10 mins. Then seems to vapor lock.. should it have charcoal canister .and electric fuel pump. With regulator?

Dean Lindsey, it should have a vented fuel cap. If it’s been replaced, you might have an unvented cap, as all cars since about 1970 have required. A test is to leave the cap loose or off, and see if that solves your problem. You could add a charcoal cannister and such, but it’s a lot of extra plumbing to retrofit, and you would have to add a vent in the top of the tank to plumb it into.