In this episode of Project LS Next, we find out what Mike Mavrigian’s 440 cubic-inch LS engine made on the dyno—after he installed the induction system, ignition, and a pair of valve covers. Don’t cheat and scroll to the end of the story—that’s not cricket.

Induction System

We opted to go with a carbureted setup using a Holley single plane intake manifold and an 850 cfm Ultra HP double pumper carburetor. The intake is designed for LS3/L92 applications with an optimum operating range of 2,500 to 7,000 rpm.

During test fitting, we checked the port match between the Trick Flow GenX 255® cylinder heads and the Holley manifold. The port alignment was so good we saw no need to remove any material from either the manifold or head ports. It was as though Holley and Trick Flow consulted with each other when designing these parts.

The manifold has grooves around each intake port for O-ring seals. Holley has an O-ring kit under part number HLY-508-22. A light coat of lithium grease or Vaseline helps keep the seals in place during installation.

The 850 Ultra HP carburetor features lightweight aluminum construction, mechanical secondaries, an electric choke, four-corner idle, clear fuel bowl sight glasses, and optimized street/strip calibration. The carburetor is 100 percent wet-flow tested and ready to run.

Valve Covers

We chose Holley’s new cast aluminum valve covers that feature bosses to mount a set of coils without the need for ugly coil brackets. The appropriate MSD coils are MSD-82878. The earlier LS1/LS6 style coils have shorter spacing and won’t fit.

Our Harland Sharp roller rockers hit the undersides of the stock height valve covers. Rather than going to taller valve covers, we installed a pair of ¾-inch tall ICT billet aluminum spacers to get the necessary clearance. The spacers seal to the cylinder heads with an OEM-style O-ring. The valve covers use a factory type O-ring that seals to the spacers. The valve covers and spacers were secured to the cylinder heads with 3.500-inch long stainless steel socket head cap screws.

Ignition

Since this build uses a carburetor, the only electronic control system needed is for ignition timing. We used an MSD 6LS-2 controller that connects to the coil harness, water temperature sensor, cam sensor, and crank sensor. The controller features a choice of six pre-programmed ignition curves, or you can create custom ignition curves on your computer using the included software.

Per Trick Flow’s recommendation, we used NGK V-Power spark plugs gapped to 0.045 inch.

Dyno Session

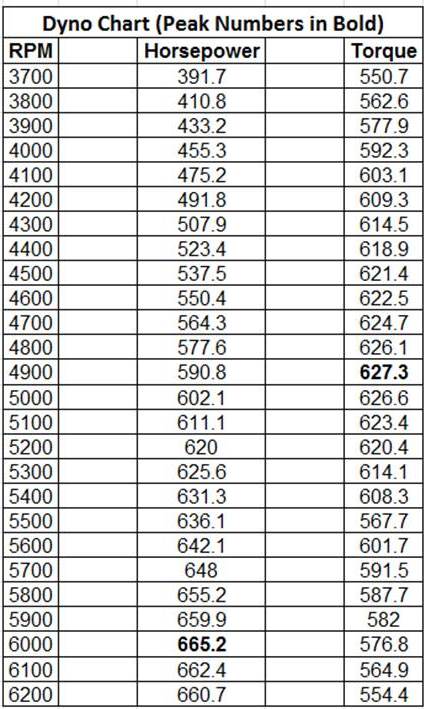

We dynoed the engine at Gressman Powersports in Fremont, OH. Scott Gressman plotted a custom ignition curve using the sofware supplied with the MSD ignition box. Timing at idle was set at 15 degrees, which ramped up to 27 degrees by 2,500 rpm.

The Holley Ultra HP carburetor came with #80 jets in the primary and secondary metering blocks. As we approached peak power levels, the Superflow dyno’s air/fuel monitor indicated a slightly lean condition. Gressman swapped out the jets for #90s, which improved the power and torque numbers but put the A/F ratio on the rich side. We settled on #88 jets for the final power pulls.

The engine made a best of 665.2 horsepower at 6,000 rpm and 627.3 ft.-lbs. of torque at 4,900 rpm. Throttle response was extremely snappy. Given more dyno time, we could have made some incremental power increases by messing with the carburetor and ignition timing. All in all, our LS Next will make a nice stump puller in a mid-size muscle car or an F-body.

If you’re looking for a DONOR F-body, I’ll be your huckleberry!

Not bad but I would have expected more power.My 402 dart motor with AFR heads made 627hp 570 trq and I’m shifting at 7200.