Spring rate is a key factor in choosing the right springs for your suspension system.

Spring rate is defined as the amount of force it takes to compress a spring one inch. A 200 lbs./in. linear spring, for example, will compress one inch when a 200-pound load is placed onto it. If another 200 pounds is put onto the spring, it will compress another inch. The rate of the spring, however, remains constant at 200 lbs./in.

Ideal spring rates can vary depending on vehicle application and personal preference. For example, a lower spring rate (soft springs) will provide a good ride quality but offer less body-roll control than stiffer springs. Higher spring rates (stiffer springs) will reduce body roll but provide a harsher ride.

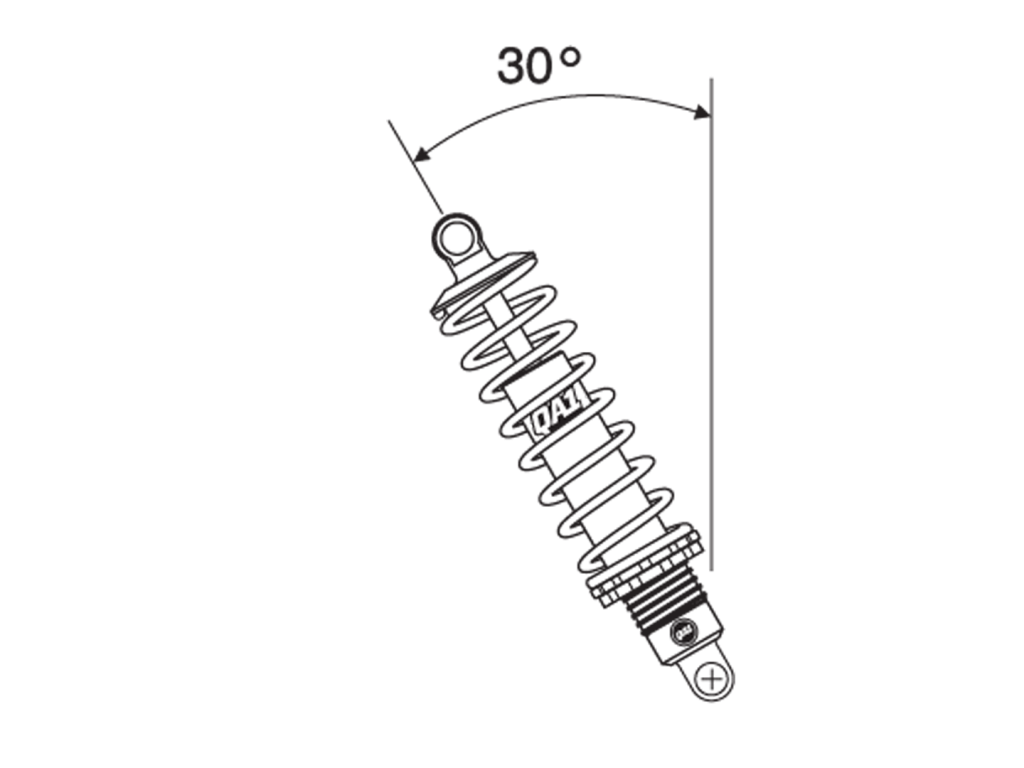

Another important factor in choosing spring rate is mounting angle. If your spring is mounted at an angle, you will need to consider that when calculating your optimum spring rate. The greater the installed angle, the stiffer the spring rate must be to support the same weight. Fortunately, the suspension experts at QA1 Precision Products offer up a good formula for factoring the mounting angle of your springs.

Start by measuring the angle of your springs from vertical in degrees (A), and then use the handy chart or accompanying formula below to determine your Angle Correction Factor (ACF).

Shock Angle Angle Correction Factor (ACF)

10°………………………………….. .98

15°………………………………….. .96

20°…………………………………. .94

25°…………………………………. .91

30°…………………………………. .87

35°…………………………………. .82

40°…………………………………. .77

45°…………………………………. .71

Formula: ACF = COS∠A°

Next, determine the spring rate needed if the spring is installed straight up. Then, to compensate for installations at different angles, find your Angle Correction Factor (ACF) using the chart or formula above and divide your straight-mounted spring rate by your ACF.

Example:

Straight-Mounted Spring = 200 pounds

Spring Mounted at 30° = 200/.87 = 230 pounds

Which means 230 pounds represents the spring rate needed when mounted at a 30° angle to equal the spring rate of 200 pounds when mounted straight up.

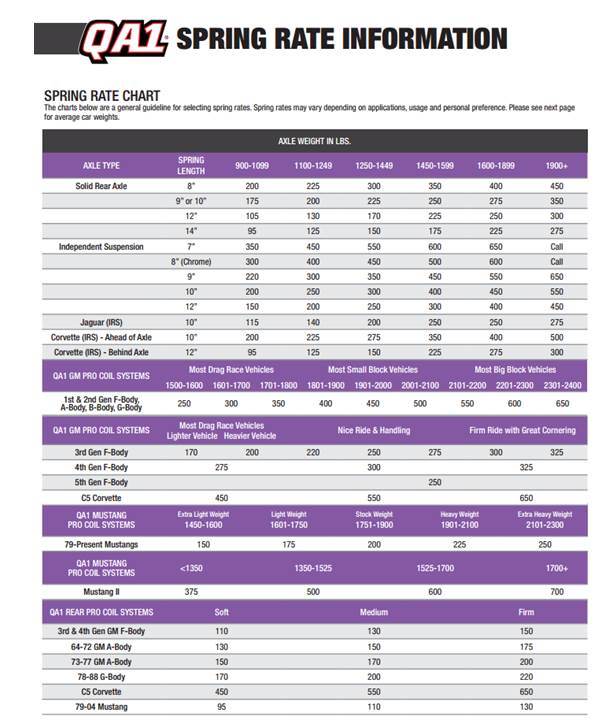

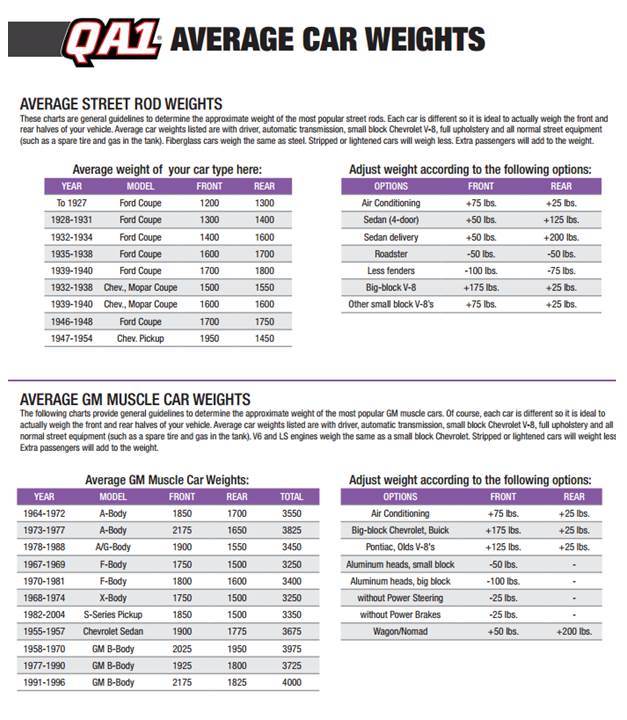

To give you a good starting point for choosing your spring rate, QA1 offers a few helpful charts that factor in vehicle weight and suspension types:

Spring Rate Chart

Vehicle Weights

Using these charts as a starting point, along with the ACF chart/formula above, you’ll be able to zero in on the best spring rate for your application. Vehicle usage, driving style, and personal preference will play a role in your choice. Other suspension components, such as sway bars and shocks, may also affect the ideal spring rate for your vehicle as these pieces often work in tandem with your springs.

Just remember—mounting angle is a key factor, too.

Comments