Q: My Holley-equipped vehicle has a stumble from a dead stop. Someone told me the accelerator pump nozzle may need resized. How do I know if I need to change an accelerator pump and how do I determine the proper size?

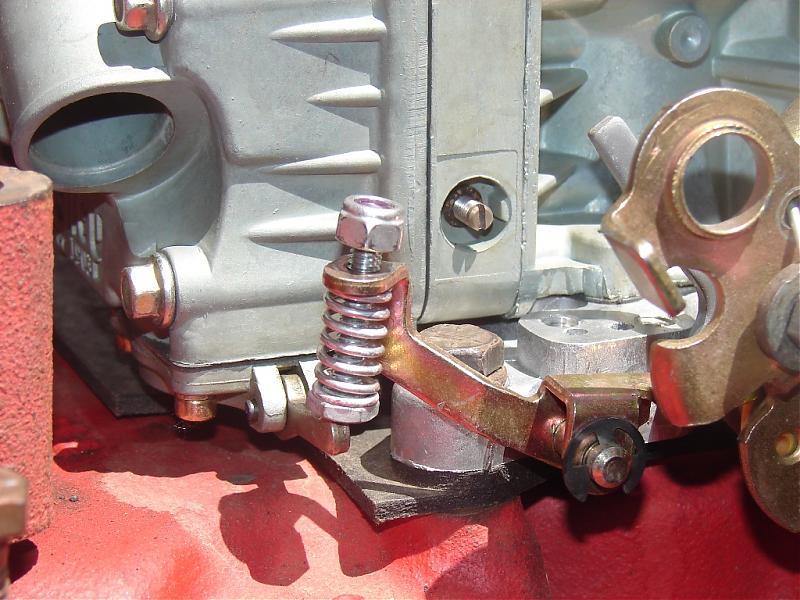

A: It’s true that one of the most common causes of stumble is not having an adequate accelerator pump shot. Before we get into changing out your accelerator pump, take a look at its discharge nozzle and make sure it’s getting enough fuel. If not, you should inspect the pump diaphragm for a hole or tear. You should also make sure the pump passage is clear of trash or debris. Next, check the adjustment on the pump. To do this, open the throttle all the way, push the pump arm lever down, and adjust the pump override spring to obtain .015-inch clearance between the accelerator pump arm and lever.

Now you can turn your attention to the accelerator pump.

Even with correct jetting, carburetor performance will be poor if the accelerator pump nozzle (squirter) diameter is incorrect. If a car is sluggish during initial acceleration and a puff of black smoke blows out of the exhaust exit, the accelerator pump nozzle diameter may be too large. (Fuel spilling out of the vent tubes is another possible cause.) As with jetting, determining the best squirter diameter is accomplished by trial-and-error testing. Simply adjust the size up or down until the best performance is achieved.

Holley created this excellent video that shows how pump size affects performance.

Keep in mind, you can also fine-tune accelerator pump performance by adjusting the pump lever settings we mentioned earlier. For oval track use, the lever should be adjusted so that there is no play in the pump linkage when the throttle is closed. This will assure that there will be no lean stumble when the carburetor comes off idle. Drag racing calls for an approach that yields the hardest starting line launch possible with a foot brake. In this case, the pump lever override spring should be adjusted so that fuel starts to discharge through the nozzle at an engine speed lower than launch rpm. If a car leaves the starting line at 5,000 rpm, the pump shot should begin at 4,700-4,800 rpm. The key is to have no slop in the accelerator pump system at starting line rpm, so that the pump shot isn’t used below that rpm.

As you can see, accelerator pump sizing and settings can play a big role in your vehicle’s performance.

Want more Q and A features? Find all of our Mailbag articles here.

That makes everything clear. Thanks.

Hello together,

I have a 390cfm Holley on my FJ40 2F engine. There is a possibility of no gasoline discharging through the accelerator nozzle when the accelerator pedal is slowly pressed through.

Greeting Durner christian

Had a rebuild 302 and a new Holley 4160 carb. Standard it comes with a #31 squirter and orange accelerator pump cam. It had an off idle hesitation. After trying different sizes squirters and cams, I ended with a smaller #25 squirter and the green cam. Now it’s perfect.