Do you know of or are you a good source for questions about timing? I’m not talking about the basics. I think I have that figured out. A question I have is why when I set the total mechanical advance on my race car I’m told I want it all in by somewhere close to 2,800 rpm. Some people lock the timing at 32 or 34 degrees and just run their car that way. Why does the engine not need more timing as the rpm’s go above 2,800 rpm? A friend that runs a computer-based timing control says he can add timing as the rpm increases so why isn’t mechanical advance set up to add more? Another question I have concerns advance curves and how they might be used to tune a car for drag racing? Can you help me?

R.J.

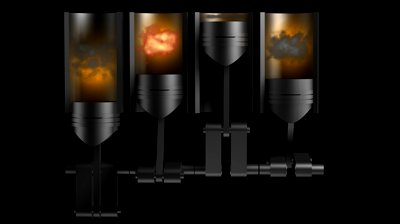

Jeff Smith: You have a few very good questions here, so let’s get started. The reason for ignition timing is because the explosion that many think occurs in the combustion space when an fuel-air mixture is ignited is not what really occurs. Instead, when the spark plug fires, a flame front is created around the tip which travels across the combustion space much like a fire burning across a field of dry grass. This burn process is quick, but still takes time to occur. By beginning the combustion process before top dead center (BTDC), this allows the flame front time to create pressure. The ideal piston position to create maximum downward pressure on the crankshaft is between 10 to 20 degrees after top dead center (ATDC). The thought might also occur that as engine speed increases, additional time will be required to allow this flame front and pressure to build, which is true.

At low engine speeds—idle to around 2,000 rpm—not as much timing is needed since the engine is spinning relatively slowly. This is why ignition curves were created to produce more power at higher engine speeds as additional timing is required. You asked why some engine builders set up crank trigger ignitions with fixed timing. These generally are single-purpose drag race engines that only operate at wide-open throttle (WOT) within a narrow rpm band so an advance curve is not necessary. But for street engines, a curve is generally used to improve drivability and throttle response. Plus, a fixed ignition advance of 36 degrees in an engine with high compression will make the engine difficult to start when hot. That’s why engines with fixed timing are also configured with an ignition start retard to not abuse the starter motor.

You also asked why engines don’t need more timing above 2,800 rpm. This is an arbitrary rpm point, but based on experience, a fixed timing number of 32 to perhaps 40 degrees seems to work for most normally aspirated, pump gas engines. It is possible that if we doubled the engine speed from 6,000 to 12,000 rpm that timing changes might be necessary, but the doubling of speed from 3,000 to 6,000 is not sufficient to demand major changes in timing.

Another issue worth considering is that as combustion space (the entire area of the chamber and piston top) design improves, the need for advanced ignition advance (timing before TDC) is reduced. Not long ago, 40 degrees BTDC was the norm. Today’s modern engines often demand 30 degrees or less total timing. This is a positive step since initiating the spark 40 degrees BTDC creates a small but still significant amount of negative work—which means the engine must work against building cylinder pressure with greater ignition timing. By starting the timing later, less negative work is required and the engine makes more power.

As to your question about ignition curves for drag racing, this is generally not a big issue since in a drag race application the engine will normally be operating almost entirely at engine speeds above 3,000 rpm where the maximum advance has already occurred. The only time the curve may play a part is on the starting line for a street car where the launch rpm is below 2,500 rpm. Experimenting with timing at that point often results in beneficial improvements in 60-foot times.

There is certainly much more to this ignition issue but these basic points should provide enough material to help you think about ways to creatively improve tuning techniques for your specific engine.

Jeff writes very good articles on a regular basis.

I agree with the info Jeff provided in the article

I used to race cars also a few years back. I still have an old Sun syncrograph machine for the old distributors with advance systems. I would consider selling it since I don’t use it anymore.

Hi mate I would be interested in your distributor machine Cheers

This all is to improve your brains! Because we’ll all be on hoverboards soon, right?…Uh Oh. [If anyone ever reads this message in a bottle, remember, please, it’s only masochism!]. Jeff, call me about my laws of physics newsletter. Sincerely, Michael Gorchovphv

Sea level settings…..Not 8000 foot or even 11000 ft above sea level. There really is a lot to consider. Cam,compression, nitrious,elevation,fuel,cfm size… Remember a pinging engine will soon be a dead engine and slow timing will wipe the exhaust valves out.. This is a great article! Thanks Jeff.

I know I personally lack the appropriate knowledge about timing and can use all the help I can get!

[…] purpose of vacuum adance quite well in relation to charget density in the combustion chambers. http://www.onallcylinders.com/2015/0…-race-engines/ google_ad_client = "ca-pub-7865546952023728"; google_ad_channel = '9087857244'; […]

Hi Jeff, this is an Outstanding Knowledge of Timing.I am a 40 plus yr master tech.now retired.Great Job Jeff

Well well written and crystal clear for a newby. Thanks. I now know why vacuum advances the timing under lighter throttle settings. Thanks again.