For most racers and enthusiasts, a wheel alignment is something that you seldom ponder, especially when it comes to performance. After all, horsepower has become cheap and easy to get. And wheel alignments–well, those are for keeping your tires from wearing out, not adding performance.

Or are they?

For some racers (a good example is an NHRA Stock Eliminator competitor), finding performance by adding more and more power isn’t usually an option. Most of those cars are maxed out power-wise by the rule book. Because of this, racers look for every possible advantage–even ones found outside of the engine compartment. One place to look is the front end.

Precisely setting up the front end can contribute greatly to the performance of the car. It’s something many class racers really work on, and even the pros with high-end tube frame cars give it plenty of consideration. The reasons are performance and safety. The bottom line is there’s more to wheel alignments than simply keeping your tires from becoming prematurely bald.

So where do you begin? That’s simple. Consider what a wheel alignment really is:

The Cornerstones Of Wheel Alignment

Front-end alignment is important, but it also carries with it a new set of terms. In reality, all three of these wheel alignment terms deal with geometric angles and basic measurements:

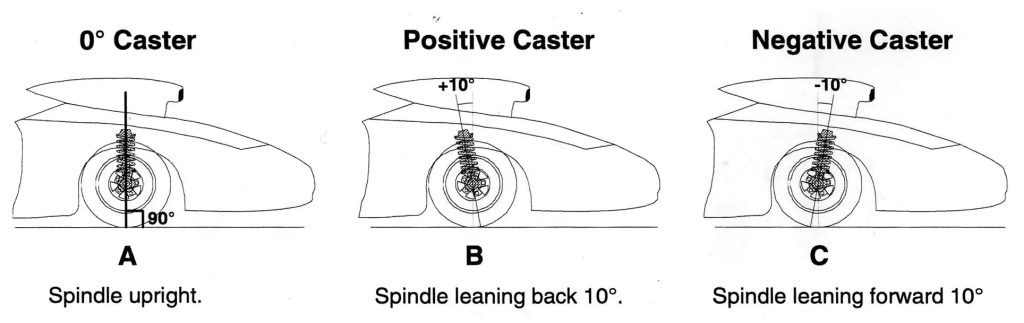

Caster: Caster is the backward or forward tilt of the spindle as you look at it from the side of the wheel and tire combination. When caster is positive, this means the wheel assembly tilts backwards, which in turn, places weight behind the tire contact patch. If the caster is negative, this means the top of the spindle is tilted forward, which places weight in front of the tire contact patch. Caster is expressed in degrees, and measures the amount the centerline of the spindle (or in the case of a solid axle, the kingpin) is tilted from true vertical. Typically, caster figures seldom go beyond -3/4 degrees (negative), and in almost all high performance applications, some amount of positive caster is required.

Why?

Think of positive caster as a means to “self center” the steering. If you’re familiar with bicycles, that’s why touring bikes have a fork that’s kicked out. It provides a big chunk of positive caster that gives the rider a lot of directional stability. In contrast, a mountain bike has a fork that’s much closer to vertical. That provides lightening quick turns, but very little directional stability. You can easily ride the touring bike without your hands on the handlebars. It’s not quite as easy with the mountain bike.

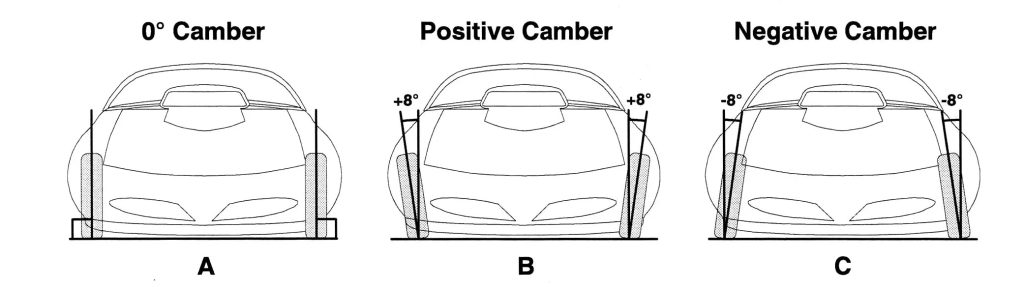

Camber: Think of camber as the tilt of the wheel at the top (tilting in or tilting out). Camber is expressed and measured in degrees and looks at the tilt of the wheel from true vertical. Pretend that the wheel and tire combination tilts out at the top. This means the camber is positive. If the top of the wheel tilts in, then the camber is negative. The real idea behind camber is to keep the tire planted squarely on the pavement. This creates maximum front tire grip. In theory, it sounds like zero degrees of camber is good (and generally speaking, it is for a tube frame car). That isn’t always the case for cars that originally rolled down a production line. Most production line cars require different camber figures (while at rest) so that good grip and tire wear is maintained as the car travels down the road. Typically, a car with a small amount of negative camber will exhibit better drag strip handling characteristics without killing the tire.

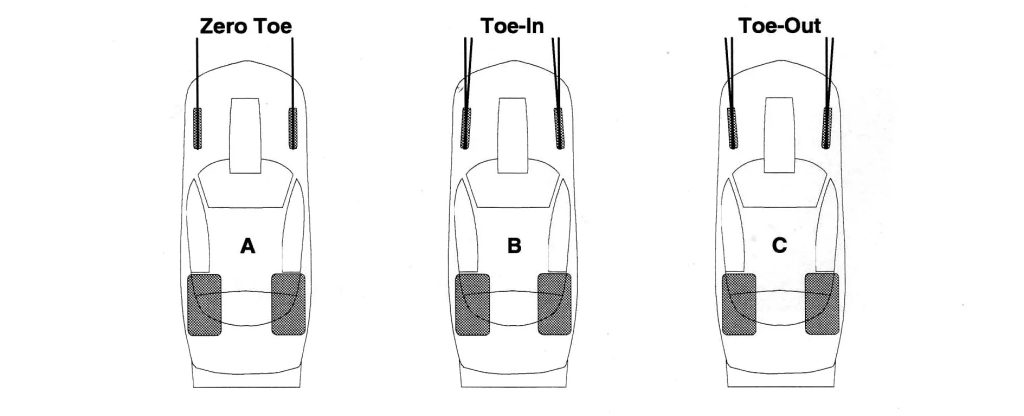

Toe: Toe, whether in or out, is the difference in distance measured across the face of the front tire and that of the trailing end of the same tire (viewed from head on). Toe-In is a pigeon toe look with the front of the tires pointing inward. Meanwhile, toe-out is just the opposite with the front of the tires pointing out. The actual toe setting is seldom zero. In most applications, a small amount of toe-in (usually something in the range of 1/16-inch or 1/32-inch) is common.

Why is this?

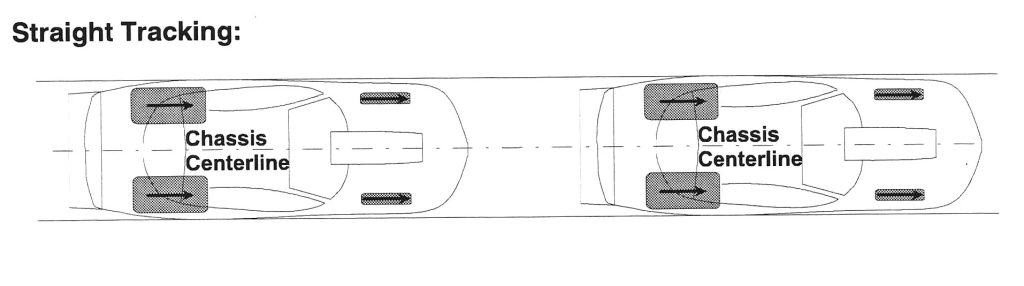

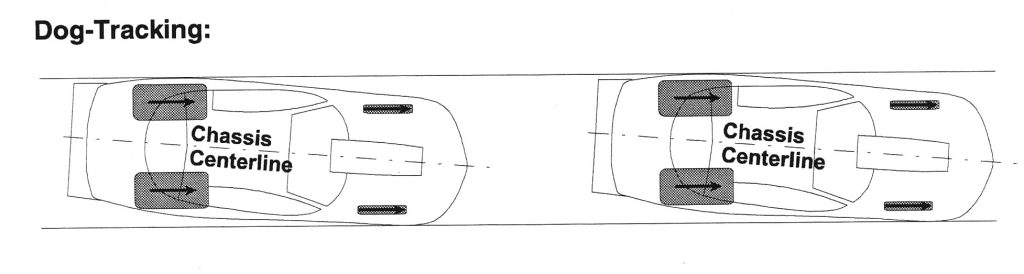

As the car moves down the road, the dynamics present on all of the steering and suspension components tend to force everything outward. This results in almost zero toe as the car is in motion. Before you can go any further in the wheel alignment, the car must be square before. In other words, the car has to track straight down the drag strip. Pro chassis builder, Jerry Bickel notes:

“If the rear axle is turned slightly in the chassis, the tires point off line and the rear of the car is steered in that direction,” he said. “The driver has to compensate by turning the steering wheel until the front wheels are pointed in the same direction as the rear wheels. The car travels sideways or ‘dog-tracks’ down the track.”

Aside from being a bit of a handful to drive (stability suffers), a dog tracking car isn’t aerodynamic. Squaring the chassis isn’t that difficult. Usually a straightedge of some sort is clamped to the axle housing (wheel bearing flange) or back brake rotor (or drum) and then measurements are taken from the straightedge to the frame (on both sides of the car).

Dialing In Caster, Camber & Toe

In the chart that follows, I’ve compiled GM’s wheel alignment specifications for 1993-2002 GM “F” platforms and compared it to a 1967-1969 Camaro. There’s a considerable difference between the two and it shows you what you’re up against when it comes to a drag race wheel alignment. If you decide to drag race such a car (and I’ve had a few of each), try adding more caster (up to six degrees if you can, and it won’t be so easy with the early car). Keep an eye on the toe-change while the car is jacked through its travel. Toe-in change must be kept to a minimum, and the very last thing you need is toe-out as the front end “travels.” This usually isn’t a problem with the front suspension on the newer Firebirds and Camaros, but it can plague some earlier cars.

Before you do a wheel alignment on any drag car, place weight in the driver’s seat that is equal to the driver’s weight. Shot bags, or weight lifting equipment will work. Be sure to top the fuel tank with the appropriate level of gasoline and set the tire pressures to the level you normally race with (i.e. high pressure on the nose, and lower pressures at the rear). With the car on the alignment rack, jack the nose up to duplicate a normal race “attitude” (an inch or two seems to be about right). Jack and block the back of the car to compensate for the height of the front wheel alignment turn tables. The car is ready for the alignment.

Remember that every car will be slightly different, but here are the OEM alignment figures:

Sample Production Line Wheel Alignment Specs

Setting 1993-02 “F” Body 1967-69 Camaro

Caster 4.4° ± 0.5° 1/2° ± 1/2°

Camber 0.4° ± 0.5° 1/4° ± 1/2°

Total Toe 0.0” ± 0.2” 1/8” ± ¼”

Since every different car in competition will be different, use the following basic guidelines for wheel alignment:

- Camber should be set at zero; you should try to keep the front wheels straight up and down.

- Toe-in should be as close to zero as possible on a production line chassis. On a strut-equipped tube-frame car, Bickel recommends 3/16-inch of toe. Toe-in change should be kept to an absolute minimum and be positive that the car does not exhibit any toe-out while the nose is in the air.

- Caster should be between 3 degrees and 6 degrees. On a strut-equipped tube chassis, builders like Bickel recommend 12-14 degrees on cars that run up to 160 miles-per-hour. Over that speed, and the recommendation is usually 10 degrees.

- Bump steer must be eliminated at all costs.

SOURCE: Jerry Bickel Race Cars, Inc.

Good article.

I worked on Paul Blevins 65 corvette and one of the tricks wasG.M. sold upper control arm cross shafts that were used on accident cars that you couldnt get the proper degree,s out of it after re-alliahment,in other words the car was still bent,but with these you could get as much possitive caster that you needed.Just thought i would share this in case somebody cant get enough caster possitive or neg.,good luck!

So how about some ideas on how to change things. I have a chevelle and am curious how to get these “ideal” measurements.

Stock wheel alignment specifications for your Chevelle should be close to the following (these are the specifications from Chevy’s 1969 Service Manual):

Caster: Negative 1-degree plus or minus ½-degree

Camber: Positive ½-degree plus or minus ½-degree

Toe In: 1/8” to ¼”

If you re-read the article, you’ll note for a drag race alignment on a production-line car, you’re shooting for camber settings as close to zero as you can get, toe that is as close to zero as you can get, and as much caster as you can come up with. In addition, you go over the article again, I gave you some tips on setting the car up so that it mimics the race “attitude”.

Over time the frames on cars such as yours tend to sag. You can’t make up the difference with shims on the upper A-arm cross shafts. In order to come up with zero camber or a bit of positive camber, you’ll probably need a set of offset upper a-arm shafts for the Chevelle. These shafts will allow you to improve the camber. Summit Racing sells them under Moog part number K5250. You’ll need two sets for the front end. And by the way, these are very nice, high quality kits.

Toe is pretty easy to set. As pointed out above, try to shoot for zero toe. At least, go with the minimum factory spec of 1/8-inch. This should be total (both sides).

Caster, on the other hand, might be a bit more difficult. The factory specs call for negative 1-degree, plus or minus ½ degree. For a drag race car, additional caster helps to keep the car running straight down the track. It’s nice to see positive 3 to 6 degrees, but honestly, it’s not always possible. Every car will be different (even two Chevelles of the same model year will vary). Often, you just take what you can get.

Hope this helps.

Always enjoy any article written by Wayne Scraba!

Great read! 33year ago I built my first tube chassis drag car a Maverick thT I still own today! I made my own tubulare upper and lower control arms and used the longer rear application koni shocks as I was going to foot break the car first! With the extra front end travel the bump steer became an instant issue! Finding the correct location for the rack and pinion and correct length was educating to say the least! But I was totally amassed how well the car drives and handles! I’ve found the car very out of control several times due to very bad track conditions over the 30 years of racing! Can’t complain about the handling of the car!

I have a 67 Nova with an aftermarket TCI Pro Touring front suspension that I use for drag racing. I chose the pro touring option because it had more front end travel than the other TCI/Heidts front suspensions. It bolts on at the firewall and replaces the entire front suspension. On a car like that, would you suggest using specs similar to the tube chassis specs you gave or the factory numbers?

I suspect your TCI subframe is a double arm, coil over shock setup? I’ve never looked at one first hand, but from the photos I’ve found, it looks like a nice package. If it were me, I’d still try and aim for as much caster as you can get (when I look at the specs, it looks like it will go to 6-degrees caster). With this setup, I’d try to keep the toe to zero and the place to start with the camber settings should be zero. That should put you in a good place to start (at least). And don’t forget to watch for bumpsteer!

I need to know how to ajust the shocks for my rear end on my 70 tube frame drag car

I’m working on an antique altered drag car From the 60’s with a straight axel. The owner says that the front end wobbles. It looks to have about 20 degrees of caster and the wheelbase is 102″ I’m guessing that it should have about 5 degrees caster, but haven’t found any rule of thumb numbers till this article.

Thanks,

Doug Coffman

Hello, we have an rear wheel drive shortcar with double wish bone in front, and double wish bone rear axel.

We starting from an grid on tarmac how to get more tracktion on rear wheels, is it possible to adjust upright(spindle) angel to get better grip on tarmac. Positiv og negativ caster on spindle(upright) will this help us get more tracktion?