Proper engine break-in procedure is critical.

The right steps during this procedure can save your engine, your bank account, and ultimately your sanity. With help from the engine experts at ATK High Performance Engines and Summit Racing, this post will provide you with invaluable tips to help protect your engine during the critical break-in period.\

Start with an Inspection

Before you start the engine, ensure that all accessories, such as the headers, alternator, and power steering pump, are tight and check for any water or oil leaks. Even if your engine came as a complete, turnkey assembly, it’s best to check all major components such as the distributor, spark plugs, ignition wires, carburetor. These items could have been damaged or disturbed during shipping.

Lubrication Considerations

When installing an oil filter, fill it about half way with oil, lube the rubber gasket the surrounds the filter with oil, and then tighten by hand. Consider using a premium brand oil and filter—a cheap filter will not be cheap if it costs you an engine. Use a 5w-30 or 10w-30 motor oil with an engine break-in additive (ZDDP or zinc camshaft additive), especially with flat tappet camshafts.

Prime the Pump

To avoid dry start-up, it is best to prime the oil system with an engine-priming tool or a pre-luber, even if the engine has already been dyno tested.

Use Conventional Wisdom

Even if you plan on running synthetic oil, you should break a new engine in with a conventional, mineral-type engine oil for the first 4,000-plus miles. If you fail to follow this procedure, the piston rings may never seat.

Change Oil Often

On freshly built engines, you’ll need to change your oil and filter much more frequently. After using a break-in oil, you should change your oil at 50 miles, 500 miles, and 1,500 miles. Again, at 4,000 miles or so, it’s fine to switch to a synthetic oil if you choose.

Timing is Everything

Set the ignition timing after starting the engine. The starting point for most carbureted engines is 34 degrees before top dead center with vacuum advance disconnected at 3,000 rpm. Some experimentation with timing is required for optimum results with locally available fuel, but it should be between 32-38 degrees BTDC.

Take Care of Your Flat Tappets

If your engine uses a hydraulic flat tappet camshaft, keep the engine between 2,000 and 2,500 rpm, with no-load on the engine for the first 30 minutes. This is critical to break in the camshaft, although roller cams really do not need to follow this step.

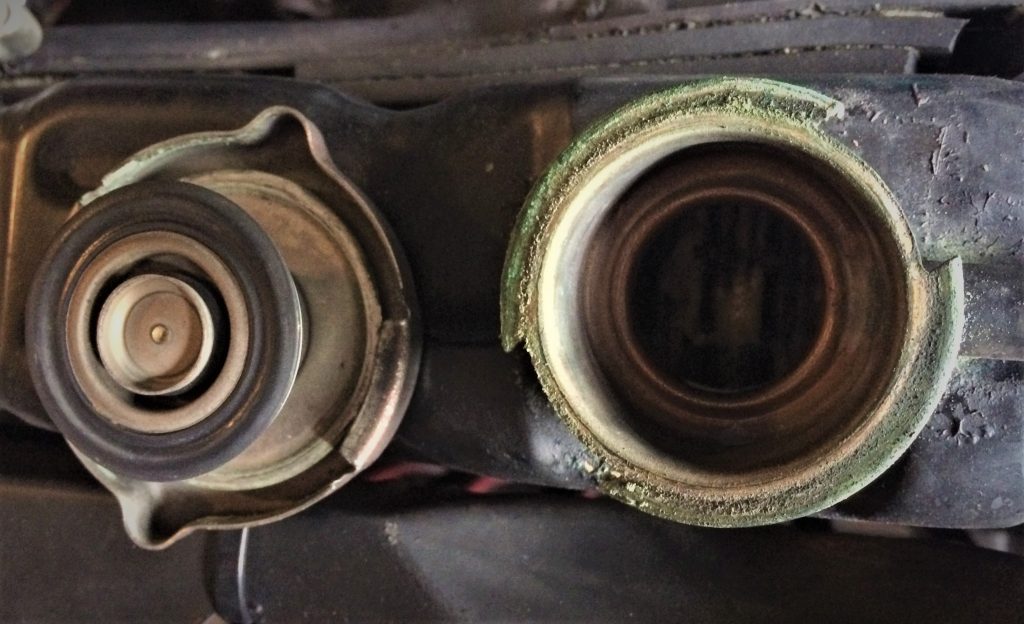

Keep Your Cool

Most often, the cooling system on a fresh engine swap will have a lot of trapped air, which will lead to wild temperature gauge readings and possible water pump cavitation. To help alleviate trapped air in the cooling system, fill the cooling system with a 50/50 mix of quality coolant and water a few hours before you plan on starting the engine. Leave the radiator cap off during this time. This tends to help purge a fair amount of trapped air before you start the engine. You can also use a lever-vent type radiator cap on your radiator so you can manually purge trapped air while the engine is running. Your normal cap can then be re-installed after the engine cools off.

Vary the Load for Initial Break-In

For the first 200 miles, drive the vehicle with varying speeds and loads on the engine. Occasional full throttle runs from a rolling start (2,000 rpm or so) to 4,500 will help seat components such as piston rings, but the engine should be cooled after doing this. Also, it is wise to check rocker and valve clearance after 150-2oo miles to insure adjusters are tight and lash is proper. Re-check again at about 500 miles.

Break-In Plan

Although it isn’t necessary, ATK says the following procedure will help speed up the break-in process:

- Make five or six medium-throttle accelerations to about 4,500 rpm before letting off in gear and coasting back down to 20 miles-per-hour.

- Run a couple hard throttle accelerations up to about 5,000 rpm and once again coast back down to 20 miles-per-hour.

- Let the engine cool, change the oil and filter, and check the coolant level.

- Drive the next 500 miles normally, keeping the engine below 5,000 rpm and minimizing operation at idle.

These break-in procedures all seem very good, except #4, don’t use synthetic for break-in. Many modern cars use a synthetic factory fill. A machining technique called “plateau honing” pre-breaks-in the jagged peaks of the honing process, which is what happened during break-in in the old days. This caution would apply, however, if your machinist does not use this procedure., In this case, #4 would still apply.

Unless this blog has been edited since you commented, #4 specifically says *don’t* use synthetic until after 4K miles.

You dint read so well do you?

You dint spell so well, doeses you?

Yeah you’re absolutely right synthetic oil won’t let motor break in

Absolutely right! My experience with daily drivers that came from the factory with Synthetic oil (only because factory prefers to have insurance against stupid people that goes full throttle with their new cars), is that they took an inordenately long time to seal, and never truly got a good cylinder sealing. I do very much prefer to use mineral oil for the break-in and only change to Synthetic after at least 1,000 street driven miles or so.

yes i have a question, I have a 1972 Dodge dart and the engine has been rebuilt. My lifters and rods and rings were replaced when my head gaskets blew which was right before the engine was rebuilt. After it was completed my mechanic (who was my friends dad) drove it to me. Well let me put it in his words “it runs great drove it at 102 mph all the down the hill (which is about 27 -30 miles). After i got it back it went to shop to rebuld the radiator. which was leaking profusely to begin with. then picked it up few days later and put it back in. Went to get coolant 3gallons of 50-50. And when we started her up she was knocking bad. worse than what she sounded like before. So my boyfriend checked out oil and to our surprise it was a milkshake once again.So we changed oil thinking maybe someone put water in with it and we were wrong cause it turned back again to milkshake come to find out the headgaskets have been blown again, and to boot the radiator has a leak again too. What can i do? can u please tell me. Thanks Sarina

something may have caused the heads to warp, in which case replacing the head gasket will result in blowing another head gasket. I would have the heads checked and the block deck checked. Afterwords replace the radiator and thermostat and fill with all proper fluids.

Well Joe reading your comment from almost seven years ago I’m sure you actually meant the opposite of what you actually said. “After”engine break-in no one contest using synthetic oil.

john the idiot

Loris Williams…… the rude @##$#@$ who has never made a mistake

Good stuff, but if your a local Bracket racer, like myself, break in is, 30 to 45 minutes in the garage, running, couple of laps around the neighborhood, as long as no one calls the Police, 2 to 3 low RPM passes, on a Wednesday night test & tune, back home at the Garage check everything over change the oil and back to full throttle.

Cool, thanks Rob, I was wondering about this! Since I’m building a bracket only car, I can’t just be cruising the highways, you know! 😉

I dont baby any of my builds…I tell people I do engines for, break it in the way you’re gonna drive it…never had a failure. If you do your build right, checking all bearing clearances and such, should never have a problem. I don’t change the oil at 50 miles, it’s a waste of oil. Better to pull the filter, cut off the case and inspect it…no metal, you’re good. Install new one, too off the oil, run it to 500 then change and inspect filter..

Improper break-ins can cause failure. If a new engine is ran for a long time at a constant RPM a ridge in the cylinder wall can develop. The rods stretch more at the top and compress more at the bottom with higher rpms so when the rings hit this ridge it anti-pretty. Usually, only happens if people go for a very long highway drive right after the rebuild and don’t vary the rpms like they are told to! This is why you want to take it to the redline while breaking it in here and there. It will ensure that the cylinder wall doesn’t wear unevenly.

I usually try to drive at least the first 100 miles on new engine but it’s not always practical.

dude I never heard of such break in procedures in all my life. I race cars for a living and we use race tolerances on race engines not on family cars. Your telling her to run a tight none race prepped engine wide open on a engine where they probably did not even check bearing clearances at all just throwed the engine together and run it some and shut it down and out the door and next

Nobody races cars for a living. That’s a hobby.

I agree with you Jim, if all is “done right”, critical break of cam and

Seating the rings are the biggest issue of concern, as long as you have the clearances correct.

Keep a fresh fire extinguisher close by..seen a lot of close calls with fuel leaks on new motors. Once saw a fuel leak drip onto a drop light and burn up a corvette because there was no extinguisher anywhere in the shop…

yeah & dont buy a performer intake if you have a holley d/p in my case i had to buy a adapter plate to keep the fuel from boiling and vapor locking my engine back then the fuel was ok to run

[…] Here are my thoughts on this, and I may be wrong, but this is my experience on using a lot of oil on a new engine. Did you have the heads rebuilt? You could be getting oil splashing on the valve stems and this is being introduced into the engine. Pontiac heads have oil shields under the valve retainers/on top of the springs. Some guys leave these off ( which you can) if you have a big lift cam and there is a clearance issue. These do help with oil control and why Pontiac used them. Did you install new valve guides or have them knurled? Sometimes a shop will knurl the valve guides to save money rather than replace them IF they are marginal and knurling will work. This is not the best approach as oil can still get down the valve stem and into the engine. New steel inserts can be installed and then reamed to bring back the factory specs with the new valves. Did you have the umbrella seals installed on the intake side? If the valve guides were not cut down to use teflon seals, these are used on stock Pontiac heads and usually come with an engine rebuild kit. These wipe oil off the valve stem as the valves go up and down in the guides. In addition, there are the small rubber O-ring seals that go under the valve stem split locks which prevents oil from going through the split locks and running down the valve stem and into the engine. Oil sealing on Pontiac heads is important and all three, oil shields, O-rings, and umbrellas seals should be used along with new valve guides. When I rebuilt my 400CI and assembled my heads, I won't tell you what I left out and found my engine sucking up oil, but it ran like a bear, and I could not figure it out……..until later. Being the engine is still "new", the piston rings may have not seated and some oil could be getting past the rings. You don't want to baby the engine or the rings won't seal – they will glaze. Learned that one too. It is recommended that you want to do several hard accelerations and decelerations to allow the rings to operate under pressure and suction. Here is some info Engine Break-In Guide: 10 Tips to Help Properly Break in Your Engine – OnAllCylinders […]

I have caprice 1994 v8 4.3l

change pistem and complete valves accessory and timing chain , honing cylinder and start

does the EMC need to be programmed ?

the mechanic I doubt he did not know how to put hoses in its original place

need picture show details of hoses connection

my car now run but rough idling I replace new Control Idle Air Valve and new map sensor and

new egr and new throttle sensor

has anyone used the Amsoil Break in Oil ?

Yes good stuff no issues on 5 engines i used it in.

I have different clearances for race and street engines. Street engines require a longer break in race engines fo right on the dyno.

If you read this man’s column why would you vary from his advice. He is the professional and knows right from wrong. No major automotive company in the world would disagree with his formula for breaking in an engine. You don’t break them in like you plan on running them. I have broke in many hundreds of engines on an electric dyno as well as water brakes and a few went into major race cars and we never abused them on break in. We ran break in engines for 18 hours with intermittent oil changes. That is how it is done professionally.

How did following “the professionals” work out for Covid?

Lol, totally different scenario,engines-viral outbreak, nope nothing in common.

I have a freshly rebuilt 350 engine that shakes while in gear (automatic) trans. is this normal until break in or is there something wrong?

could be a slight timing problem or the tranny could be causing the shakes, try to determine if the shakes happen when its in neutral or only in gear.

It’s your flywheel guaranteed , I had a 64 Impala with a 400 small block , changed to original 327 engine installed everything back and started the engine ran well but had a little vibration , pulled tranny back changed the flywheel and bouya problem solved , why ? Flywheels have a balancer on them !!!

First, check it is not engine timing/misfire/etc. Overly-retarded timing can cause a sloppy and unstable idle and generally poor performance.

Secondly, check motor mounts. Sloppy mounts are often overlooked in a rebuild and can appear to be an engine problem.

If the vibration is definitively related to RPM, it may be possible you lost a bolt on the torque converter/pressure plate, or that they have come loose, but this is a worst case scenario. Make sure no “accessories” are causing the problem, like the alternator/power steering pump, etc.

For automatics in particular, make sure the governor is clean and moves freely (with many older GM trannies, you can easily get to the governor under a cap held down by a spring clip; only attempt this when the TX is cold…you don’t need to remove it, just fiddle with it and see that the parts still move fairly well), check fluid level/condition (bubbles are no good, try letting the car sit undisturbed for a few days if you can, and try again), and make sure all mounts are correct and undamaged. If vibration worsens under load like a “stall test”, you may have a tranny problem. If it worsens with engine speed, you may have a mechanical problem (such as losing a bolt off the flywheel/flex-plate. If it worsens with vehicle speed (and is not caused by anything else), you have a transmission/driveline problem.

Always recheck later to make sure all fasteners are still tight, just as you would recheck your lugs after changing a tire. Proper and tight engine/transmission mating is absolutely essential, and in many cars they work as a singular supporting unit.

Fluid level in an automatic is critical. Do not under or over fill. Keep in mind that level reading may have do be done under certain conditions to be accurate, such as engine running in park for 2 minutes and after 5 miles of driving, etc. Your transmission may vary.

I know it’s a bump, but for anyone else who stumbled upon this article as I did, it may be helpful.

Sounds rational

Sounds more like the torque converter may not be balanced correctly. some have weights welded to them for “externally” balanced engines, while other have no weights and the engine is internally balanced. Wrong combination and it will shake a lot, and tear up transmission input bearings and seals, as well as crank rear main bearings and seals too. Verify what your build is supposed to have, and then check those part numbers.

Your right I posted the flywheel but maybe it was the other converter can remember which it was , ok is one of those things , just been over 28years ago that this exact thing happen to me . Good advice , keep up the good info..

Very enlightening. Thanks

Great read, however I’m wondering whether there would be any changes to the advice given for a motorcycle engine?

Thanks

How about a boxer engin specifically corvair cast rings (deves) 2000 miles on 10w30 still uses 1 qt per 2 hrs drive no additives witch weirdly enough is was the exact same issue before rebuild. Sent camera down cylinders no scoring. What the heck? Also first time using deves 4 piece oil rings installed exactly as instructed all cylinders seem to be burning oil going by look of spark plugs don’t think too much of deves 4 piece. Do you think it’s too late to run break in oil? Or should I toss the deves.

I just had the same issue with DEVES rings on a corvair. Going to ditch them and put in Grants

Proper break-in is critical, but no one seems to agree on what “proper” means, I’ve been told repeatedly not to use special “break-in” oils, to use the oil you intend to run in the engine or it won’t break-in properly

Ill clear it up for you real simple,yes, you have to use break in oil because it has Zinc in it and the oils we use these days dont have Zinc,Zinc helps the rings seat, synthetic oil is too slippery, it will be good later but not for break in,if you hear opinions about no braking oil versus breaking oil ,breaking oil always wins probably 8 to 2, if you just spent 3 thousand dollars on a motor or much more why take a chance?

You dont have to drive the engine like you hate it but you also dont have to granny it either, just use your common sense,when you take off from a stop get on it a bit but not like you are in a race and then let off the gas and start again,rings like this while they are trying to seat, people that encourage others to “drive it like you stole it” are people who 6 thousand dollars to them is like 5 bucks to you and me, “engine blew up? no problem, ill just build another” myself, i dont have that luxury,i have broken in 5 engines in my life for myself and friends,they all lasted 20 years plus.

Remember, its your money,the easier you go on it and the precautions you take wont take much longer than the ones you dont and you’ll be happier in the long run.

Where is the evidence that break in procedures do anything? It seams like everyone has their own opinion with no facts to back it up.

That’s a great question- I’m always trying to get to the bottom of best practice stuff to better understand it, too.

I would guess that the effects from an improper break in would only show up over time or by opening up and checking tolerances in the engine, or compression testing to see that the rings are sealing as they should?

Ben

What is happing at “Break in” is that you are mating the surfaces of parts that touch together, such as cam lobe to lifer. If these are brand new parts, the metal is somewhat soft, during break in you create enough heat to harden the surfaces, making them last the life of the engine. You need an oil that gives added protection to these surfaces until they mate and harden. This break in oil keeps the metal surfaces from galling, but allows them to wear just enough so they are not running on high points and have as much contact surface as possible, because that is the surface your oil film will be on and you want the contact forces to be spread over as large a surface as possible and ride the oil wave. If your engine is not breaking in properly, you will know within the first 10min. It will go south very quickly. If you get a good break in, your engine will continue to break in over the first year, and continue to ware at a normal rate. I have rebuilt 5 engines, all with great success, all using diesel engine oil that have Zinc in them, same as engine break in oil. I used Non-Synthetic oil for the first year, then switch to Synthetic.

In addition to what Edgineer said, know that the pistons, cylinder walls, cam lobes and lifters get No direct oiling from the engine. They rely entirely on oil splashed up from crankshaft rotation. At idle there is not enough oil splashed up to properly lubricate these parts for break in, hence the varying rpm (1500-2500 as specified by camshaft maker) for a specified time (20-30 minutes).

The results of an engine not properly broke in are evident immediately. I’ve been a mechanic for 50+ years and was taught to always follow break in procedures. I never had an engine fail. I also attended aviation engine tech school, the break in procedure for an aircraft engine has one difference to automotive break in, and that is you run the engine at full throttle for 30 minutes. The ideal results are if it doesn’t come apart in the first 30 minutes, it’s a good build and it will last. FAA regulations are strict. In the event of engine failure in an aircraft you can’t just pull over and look under the hood. Anyway back to the topic at hand. The reason engine break in was always successful was because all engine oil contained zddp (zinc) a crucial component that creates a permanent bond between two surfaces that protect against wear. Since zddp has been removed from all of todays oils to protect the life of the catalytic converter engine wear is eminent without first using a break in oil containing high levels of zddp. That said. I didn’t know the zddp content was an issue. Because even though engine break in was a must, there was no such thing as break in oil. Break in oil was created after zddp was removed from all oil. Somewhere I missed that. I installed a new cam and lifters in a 1990 f250 460cu.in. Fuel injected engine, filled the crankcase with new oil started the engine followed the break in procedure as I always did. Everything was all good drove to town about 30 miles. The engine quit running, because now the camshaft is flat. The lifters wore down the lobes completely, the valves quit opening. After I’m done sharing this experience with all of you, I’m going outside to again install new lifters and camshaft. Break in oil is only available on line no retail stores carry it or at least in my area Southern California desert. I will share my results in a day or two stay tuned same bat channel same bat time.

Thanks this was very helpful breaking in my 92 454ss engine thank you

No doubt Matt. Couldn’t agree more, no one has a base line for anything. I ate 2 Twinkies before starting my new engine and shoved a cupcake in the exhaust. Car now has 4 bazillion miles on it. Hostess rocks!

I just bought a used bike. It’s a 2010 Kawasaki Vulcan 1700 Classic from the original owner with only 3100 kms. The oil was clean and full when I checked it out so I bought it. I just found out that it has never had an oil change and the oil I’in it is the original oil. The owners manual states that the first maintenance should be performed at 1000 kms… Is the bike likely to run into any problems because of this? Thanks for your time and I appreciate help

I’ve been lusting after this very rare colored blue 2018 AMG GT-R for some time having spotted it on an Oregon dealer lot over a year ago and then just recently showing up on another dealer lot in Kentucky. It’s the only blue used GT-R I’ve seen in over a year and the price with ~ 9,000 mi on the clock is very attractive vs. new. Long story short, my local MB dealer found out the car was used as a “Press Car,” which explains the odd Carfax rpts (car was never titled). Odds are the car was not babied and probably not broken in as recommended. Common sense tells me to keep walking, but the price just dropped again and given there are no other used blue GT-Rs out there, I’m starting to wonder if maybe I should give it a try?

[…] When you first fire up your new tiller it’s important to break in […]

How do new cars with brand new engines avoid these type break in procedures?

Just like john mentioned above. New car/truck motors are plateau honed which greatly reduces break in time on rings. Although I cant say for sure, in an effort to reduce warranty costs I assume they test fire, and possibly run in, new motors before leaving the engine plant.

[…] the obvious message here is to properly break in the engine using high quality lubricants designed specifically for engine […]

Thanks for making relevant and wonderful blog . GREAT INFORMATION!!!

Did everything you said on engine rebuild. Changed oil on times running great now. Getting ready to change to a synthetic oil now and hopefully it will run a little bit cooler. It’s 383 stroker and it’s running around 190 degrees would like it to run at 180 thanks you guys. Oh forgot I live in Tampa fla. and it’s about 100 degrees today, think that’s why it’s running a little hot.

Hey Frank, thanks for reading. Not sure what kind of cooling setup you’re running (like mechanical/elec. fan(s), new/old radiator, etc.), but 190 doesn’t sound too high, particularly at idle. Ambient air temps shouldn’t have much impact on what’s going in inside your engine, so you shouldn’t notice that much of a difference in hot or cool weather. That said, I’ve heard a few folks say good things about Water Wetter. From what I understand, it cuts the surface tension of the water (in say, a 50/50 mix or 100% water) to allow the coolant to maintain better contact with the metal passages inside your cooling system. Click here and you can read some of the 150ish Water Wetter user reviews here.

If you get a motor rebuilt..how long can it safely sit during an installation into the vehicle ..until it is fired up ?

2009 le camry engine being replaced with new from Toyota short block. How do I break it in? Is freeway driving OK? What oil and change at 50, then check filter for metal. How is it cut open?

Steps to follow??

I have an atk 4.7 v8. They said just run conventional oil for 5k. I cant even find that in store anymore just synthetic blend or full synthetic. Got br30 break in oil. Changed at 50, 500, now have 1,000. Do i just go to synthetic? I dont mind running conventional untill 5k but cant find it. I was told by br30 not to run it more then 400 miles, and just get it out and run full synthetic. How do i know if im fulley broken in? I dont want to harm it by running conventional break in oil too long even if its fresh. Whats more harmful going to full synthetic too soon or running on break in oil too long?