For the third year running, Trick Flow Specialties is building the engine that will be part of the prize package awarded to the IHRA’s Summit Racing SuperSeries Top Class Champion.

Trick Flow’s first two engines—a 565 cubic inch big block Chevy in 2012 and a 598 cubic inch 460 Ford in 2013—each made over 1,000 horsepower. For 2014, Trick Flow went Chevy once again, this time a 572 cubic inch big block that features the company’s latest PowerPort® 365 aluminum cylinder heads.

We were invited along for the ride as Trick Flow assembled and dyno-tested the 572. There was a lot to cover, so we’re going to get right to it and show you what goes into Trick Flow’s 572 big block Chevy—and what comes out of it in terms of horsepower.

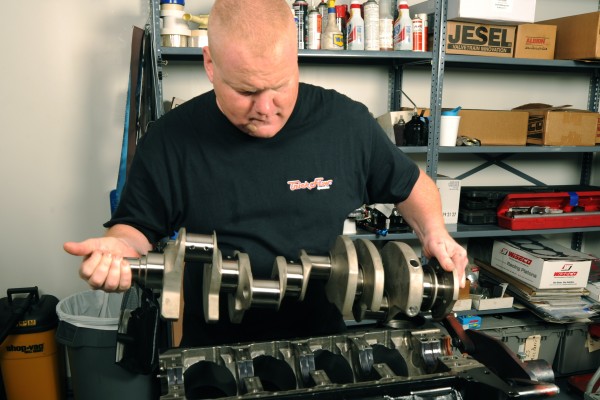

The Short Block

The 572 is based on a Dart Big M iron block. It features an improved oiling system, extra-thick cylinder walls, 4-bolt mains, and scalloped water jackets for improved coolant flow. Trick Flow used a standard deck (9.800-inch) block; the Big M is also available as a tall deck (10.200-inch).

Manley supplied the 4.250 inch stroke steel crank and connecting rods. The crank features micro-polished .125 inch radius journals, gun-drilled mains, lightened rod journals for weight reduction, and fully profiled counterweights. The H-beam steel connecting rods have cap screw ARP 2000 alloy rod bolts; each rod set is weight-matched to within two grams.

The pistons and rings are from Wiseco. The Quick 16 series forged pistons have a whopping 50cc semi-hollow dome. Static compression comes in at around 14.3:1 with the 119cc chambers of Trick Flow’s PowerPort 365 heads.

The solid roller camshaft is from Bullet Cams. The duration specs out at 285° intake/296° exhaust @.050. Lift is .918 inch intake/.874 inch exhaust with 114° of lobe separation.

Heads and Valvetrain

Trick Flow’s PowerPort 365 aluminum cylinder heads offer a great combination of big flow and cost effectiveness. Designed to extract as much power from the conventional big block Chevy design as possible, the cylinder heads are ideal for racers that want extra airflow, but don’t necessarily want to go through the hassle and expense of converting to a “Big Chief” style cylinder head.

The PowerPort 365s feature 119cc CNC-profiled combustion chambers, CNC Competition Ported 365cc intake/135cc exhaust runners, 2.350/1.800 inch valves, and Trick Flow by Pac Racing 1.645 inch diameter triple valve springs that can handle up to .900 inches of valve lift.

COMP Cams supplied the 1.7 ratio shaft rocker arms, plus the Endure-X roller lifters, lifter link bars, and Hi-Tech belt drive. Rounding out the valvetrain are Trick Flow 3/8 inch chromoly pushrods.

Oiling System

The oiling system is all Moroso: seven-quart Drag Race pan, high volume oil pump, breather tank, and vacuum pump system. Sealing the crankcase with a vacuum pump improves ring seal to prevent blowby and detonation. That’s worth extra horsepower.

Induction System

A big 1,250 cfm Holley Gen 3 Ultra Dominator carburetor sits atop a Trick Flow R-Series single plane intake manifold. The Gen 3 Ultra has a taller main body to accommodate larger radius air entries that deliver smoother flow into new fully machined, big-bore venturi. Other features include fully adjustable billet aluminum metering blocks and HP fuel bowls that hold 20 percent more fuel than traditional V-bowls. That helps eliminate fuel starvation and provides consistent air/fuel ratios.

The R-Series intake has high-flow extended runners and a raised plenum floor to improve horsepower and torque production. Trick Flow also added cast-on bosses for nitrous or fuel injectors, plus extra material for custom porting.

Other Parts

Rounding out our 572 are:

• MSD crank trigger, Pro-Billet distributor, and Super Conductor plug wires

• Trick Flow by Stainless Works headers, 2 1/4 to 2 3/8 inch stepped primaries

• Meziere 200 Series electric water pump

• ATI Super Damper harmonic damper and timing pointer

• Holley Dominator billet fuel pressure regulator

• Clevite and Durabond bearings

The Results

Once again, Trick Flow handily broke the 1,000 horsepower mark—the 572 made 1,015 peak horsepower at 7,500 rpm and 781 pounds-foot of torque at 6,400 rpm. You can check out video of the dyno pull below.

“Our goal from the start of this program two years ago was to build engines that make 1,000 horsepower reliably and with off-the-shelf parts,” said Mike Downs, Trick Flow’s General Manager. “All three engines we’ve built—the 565 big block Chevy, the 598 big block Ford, and this 572 Chevy—prove that our concept works, and can be duplicated by any racer.”

With this kind of go in their new TNT Race Cars dragster, the 2014 Summit Racing SuperSeries Top Class champion will be winning some rounds—make that a lot of rounds.

Comments