What do you hear when you listen to your engine? The primal roar of high performance? Or is it more like a cry for help?

OK, we never want to think of our engines doing anything but chewing up asphalt and waking up the neighbors—let alone crying! But even the manliest of mills can have problems, and the sounds they make can help us track down the troubles. Sometimes it’s nothing; sometimes it’s serious.

We’ve put together this quick guide to diagnosing common engine noises to help you avoid potential damage. In the event of strange or unusual engine sounds, remain calm, grab an automotive stethoscope, and be on the lookout for:

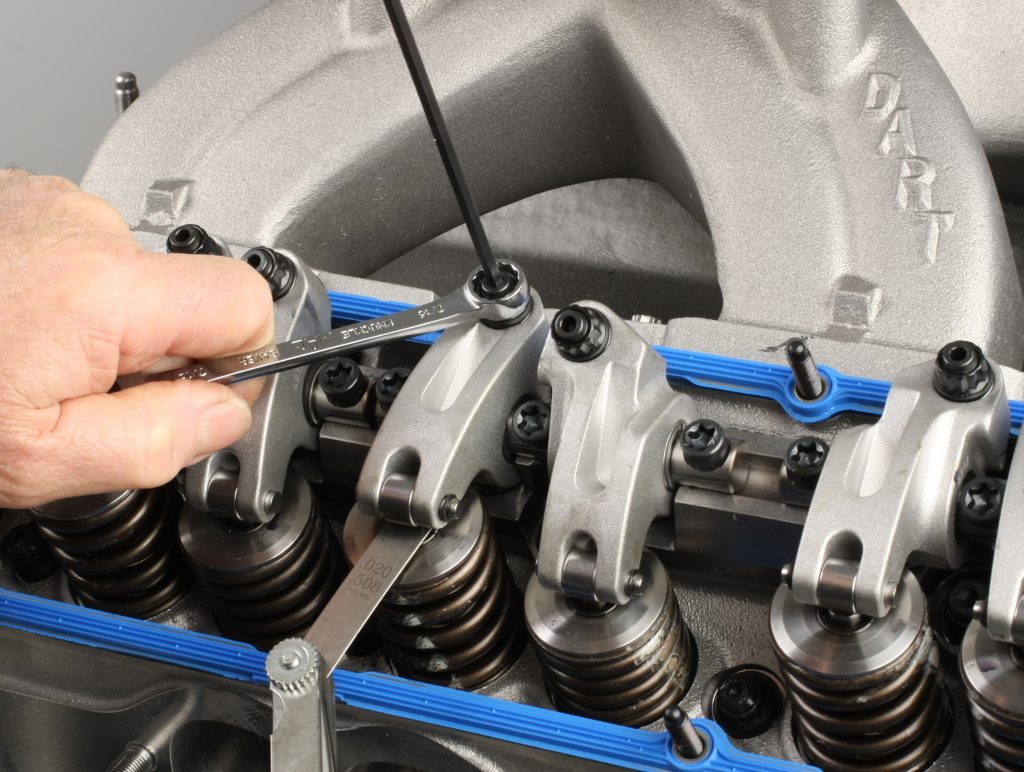

Valvetrain Noise

Valve and tappet noise usually begins as a clicking sound, or chatter, at half engine speed and may then disappear at high speeds. The cause is often excessive valve clearance or a defective hydraulic valve lifter.

To check your clearances, you can insert a thickness gauge between the valve stem and the rocker arm or lifter. If this reduces the noise, the cause is excessive clearance, and you’ll need to make the proper adjustments. If it does not reduce the noise, the sound may be caused by worn lifter faces or rough cams. Other things to look for include lifters that are moving loosely in their bores and weak valve springs.

Detonation

Detonation can cause serious damage to an engine. This condition shows up as a knocking or metallic “pinging” sound and is most commonly attributed to improper ignition timing, lean air/fuel ratio, or improper fuel octane level.

A somewhat common phenomenon in forced induction applications, detonation can be prevented by upping the octane level of your fuel, enriching the air/fuel mixture, reducing manifold pressure, or retarding the ignition timing. You can also consider an aftermarket water injection system for some applications.

Connecting Rod Noise

If you hear a light knocking or pounding sound, the noise can usually be traced back to your connecting rods. This sound is often most noticeable when the engine is at an even rpm–not accelerating or decelerating–and is often caused by a worn bearing or crankpin, misaligned connecting rod, or lack of oil.

You can single out the faulty connecting rod by performing a cylinder-balance test. This test basically shorts out the spark plugs one cylinder at a time with the engine running. Eventually, you’ll zero in on the ailing connecting rod because the noise will be reduced when its home cylinder is not delivering power.

Piston Pin Noise

Although similar to valvetrain noise, piston pin noise often has a unique, metallic-sounding double knock and is sometimes most noticeable during idle with the spark advanced. This noise is often caused by a worn or loose piston pin, worn bushing, or lack of oil.

As with connecting rod noise, you can find the offending components by performing the cylinder-balance test outlined above.

Piston Ring Noise

Piston ring noise is also similar to the valve and tappet noise above; however, it is most noticeable during acceleration. Most often, this noise is caused by low ring tension, broken or worn piston rings, or worn cylinder walls.

To troubleshoot each cylinder, remove the spark plugs and add a tablespoon of engine oil to each cylinder. Then, crank the engine for several revolutions to work the oil down past the rings. You can then install the spark plugs and start the engine. If the noise is reduced, the rings are probably the root of the problem.

Piston Slap

A hollow, muffled, almost bell-like sound is usually piston slap. This condition is caused by a piston rocking back and forth within its cylinder. Continuous piston slap means the engine needs service; however, if you only notice this sound when the engine is cold, it is likely not serious.

A continuous piston slap sound is usually caused by worn pistons, excessive piston-to-wall clearance, misaligned connecting rods, worn cylinder walls, or inadequate oil.

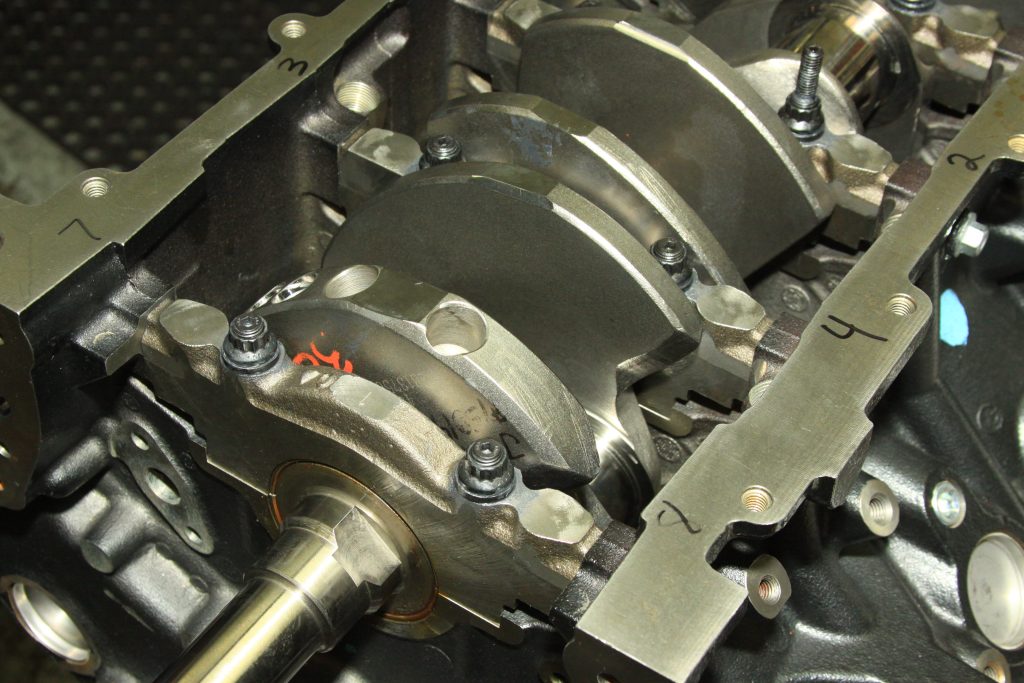

Crankshaft Knock

A heavy, yet dull metallic knock is typically crankshaft knock. Loudest when the engine is under load or acceleration, crankshaft knock can be diagnosed by paying close attention to the specific type of knock:

- A regular, rumble-like knock is often from worn main bearings.

- A more distinct knock is routinely attributed to worn rod bearings.

- A sharp, irregular knock can be from a worn crankshaft thrust bearing.

This video may help too: Understanding the Difference Between “Knock” & “Rod Knock”

Sound clips with each would be cool

Car engine trouble is a worry for most of us and how to diagnose these troubles is a question asked by many people. If your engine starts getting any sounds then you can determine that the engine has a commencement of a wicked problem. Likewise, each sound matches to each problem. Many of them are unaware about these sounds and they can pick up the sound, but couldn’t distinguish where the sound arrives from. Those people don’t want to worry, you always deliver the choice of getting your vehicle to any engine repair service for a diagnosing test.

TApets gone on mecasion Benz help

Recently installed a built 355 with new Dart Iron Eagle heads in my 1966 Impala for HRPT15. From the get-go this engine was plagued with valve train noise. The local engine builder commented that the noise was ‘normal’. I began to suspect the noise was from excessive stem-to-guide clearance and found a couple oil-soaked sparkplugs. Cancelled HRPT15 with this ride and pulled the heads. Stem-to-guide clearance was +.005″, all 16 guides. Needless to say, I will not use this machinist/builder again. He installed new guides and now everything is quiet.

So….excessive guide clearance can be another noise source.

I found that when the guides are worn, its mostly the exhaust and you can hear the exhaust under the cover

i have a 69 vette with a rebuilt 350 engine that only has 1000 miles on it. the other day while driving it just didn’t sound or feel right but ran and idled just fine. Sunday I went for another ride and after 20 minutes or so it seemed to be missing a bit more. all of a sudden i heard this loud clanging noise about 4 or five times and decelarated and pulled over. the sound stopped so since I was only a block from home, kept going. no more clang but does feel like it is missing/losing power. I am afraid of what it might be but starting it a couple more times in my garage, did not hear the clanging noise again but still doesn’t sound right or feels like it is missing. thanks

I had part of a screw end up in the motor before. Makes a racket till it spits it out, but in the meantime it crushed the ring land. Because the motor is fresh who no’s. Also if a cam lobe is going to go flat it also does it in the first few hundred miles. If nothing else works out I hope this will give you idea.

i have a 69 vette with a rebuilt 350 engine that only has 1000 miles on it. the other day while driving it just didn’t sound or feel right but ran and idled just fine. Sunday I went for another ride and after 20 minutes or so it seemed to be missing a bit more. all of a sudden i heard this loud clanging noise about 4 or five times and decelarated and pulled over. the sound stopped so since I was only a block from home, kept going. no more clang but does feel like it is missing/losing power. I am afraid of what it might be but starting it a couple more times in my garage, did not hear the clanging noise again but still doesn’t sound right or feels like it is missing. thanks

Reply

Jose, we’d start by performing a compression test to track down the location of the miss.

[…] then it is a faulty CV joint probably an axle inner CV joints…. waisay you should visit this link Sounds Like Trouble: A Quick Guide to Diagnosing Common Engine Noises – OnAllCylinders Reply With […]

What would cause a knocking sound only at deceleration?

Well done sir.my car was making noise and we’re not predicted by our local skilled mechanics .

Your interpretation on engine sounds, really help me out of the prob.

Thanks sir.

Sahil Sharma

India

I’m running my 327 rebuilt (68 Camaro), headers, aluminum heads, etc. Very noisy on acceleration with what appears to be some miss firing when accelerating from initial takeoff, and, even noisier when hot.

[…] our original post on engine noise for more […]

What if there’s only fine metal particles in the valve cover? I have a 3800 series 2 supercharged engine and the tapping noise is coming from the front top of the engine so I checked the oil for any signs of metal on the dipstick and there weren’t any. Took the oil filler cap off and saw some in the oil. It accelerates with the engine and it’s only when the engines warm to hot. Any suggestions?

Sounds a lot like a 3800 harmonic balancer problem

Why would the balancer put metal in the engine?

My b20b in my civic idles ok but its a little sluggish and sounds like a v8 when it idles. What could cause that?

Sounds like either the timings out, or its a misfire you’re hearing.

I have a small block 400 chev,just put new flat tappet comp cam and lifters in it idles sweet as but starts ticking under revs and ideas?

A few things come to mind right away such as proper break in, proper valve adjustment, and proper supporting parts like valve springs. Give the Summit tech line a call at 1-330-630-0240, and they’ll help you sort it all out!

I have a knocking noise only under load and louder the faster you go, at 30 its unnerving and 60 i expected a boom. Would that be main bearings? I want to be sure before i pull the engine out to swap it.

[…] Lori Sams will help you track down certain, unwelcome noises. Our original post on the topic, A Quick Guide to Diagnosing Common Engine Noises, will provide the extra info you need to begin curing the underlying […]

Don’t know what I’m looking for a man next to me at a light said, sounds like something is wrong. Basically at idle and reverse sounds like metal rumbling. 2002 Jeep Grand Cherokee Laredo 6 cyclinder. I’m thinking maybe crank rod or pin doesn’t feel good makes me want to pull over. Your site feedback is very important. The sound discretion is very good.Grateful for the heads up. As a female its always better to have some idea of the problem before you ask for an estimate.

Buy a gm or ford, all car problems solved then go find a guy thats driving a corvette

Have someone check the converter bolts, if the converter is loose it sounds like a rod or a crank. If that’s the problem usually the noise goes away under acceleration of much quieter. Tighten the bolts or replace them as necessary..

Could also be a cracked flywheel. That can be diagnosed with a flashlight and you would see rusty steel accumulation on the sides of the crack. Hope this helps as it only that’s a few minutes to check and eliminate. Good luck.

Knocking at idle, warm, cold, any status. Knocking is coming from area of front bottom passenger, screwdriver to pump sounds loudest. 1983 Chevy 350 5.7 V8. Could this be a pushrod for the mechanical fuel pump? I tried every diagnostic short of tearing the engine down- dropped oil pan, changed oil and filter, changed spark plugs and wires, distributor cap, rotor, etc. even took the valve covers off, made sure all lifters were operating normally by visual looking at the valves to see if they were sticking while running. Figured it was the fuel pump, recently drove to Indiana from Colorado with the RV it’s in and it got hot to where I had to let it cool down before driving several times, and installing an aftermarket electric and leaving the mech hooked up solved the problem, but then this knocking noise started the day after we got to Indiana. I can’t figure any other solution other than it’s the fuel pump. Any way to check this?

[…] Sounds Like Trouble: A Quick Guide to Diagnosing Common Engine Noises […]

I have a 2007 C6 with 147,500 miles on it. With all belts off and shortly after starting, there is a ticking noise coming from the middle of the engine that becomes a chirping sound and accelerates with rpm increase. The harmonic balancer has been wobbling a little for 50,000 miles or so without getting any worse. This noise began as a soft ticking noise about 20,000 miles ago that grew louder over time and has recently turned into a squeak an now a chirp. Like me, nobody knows what it is, but it doesn’t sound good. I’m thinking about repacking the balancer. If it is related to the balancer, I’m afraid the damage has been done, maybe a cam shaft bearing. However, I would think that would ma a constant noise. The only other thing I can think of is a rod bearing that hasn’t started knocking yet and probably caused this due to my procrastination. You thoughts, please?

My car is Nissan Skyline 2002 and I like to know the cause to the problem when you accelerating the clicking sound can be heard from engine and temperature starts to increase. Please write me your remedy … Thanks

The appearance of abnormal signs while driving a vehicle should not be ignored. Mechanical issues in certain components of the car are solely responsible for the appearance of abnormal signs like unnatural sound. The vehicle should be subjected to an inspection in order to spot and fix the mechanical issues responsible for the appearance of such signs. Besides, a car needs maintenance on a daily basis to run smoothly without any major mechanical problems. To know more about the vehicle inspection, visit https://www.bavarian-auto.com/german-vehicle-inspection/

what does it mean when you have a knocking noise sounding like a lifter and then the knocking stops and then you have a misfire on cylinder 5

I have a 69 Camaro with a 350,I’ve been having an intermittent knock when cold that sound’s like it coming from the crank.I have talked to other mechanics about this and I have changed the timing chain and the flex plate to the trans and the fuel pump, and I still had the noise. So I figured I had a broken crankshaft and disassembled the engine. The crankshaft was fine and all my bearings still looked good.

I installed a 2004r trans two years ago but the trans shop said there is nothing in the trans that would mimic that noise.Any Idea what I could be overlooking?

What could be the problem if my engine is making noise when I startup and louder noise when i accelerate and if i accelerate up to 20mph my engine cuts off completely?

I have an engine-knock in my car at higher speeds and I’m not sure what it is.i bought a used car.Car has been running pretty smooth and no problems. But sometimes I recognize this tapping noise coming from the front of my car whenever I am idle. I usually don’t hear it when I’m driving. I’ve read that it might be the valve train but I am still not sure I also checked the engine oil and it was well around max and had good colour.

I have a 2014 Forester that knocks for 2 or 3 seconds after the car has been turned off for around 20 minutes. If you turn it back on immediately…no knock. Dealer said I need a new $4000 short block. Any way to find out what it is before I pay that much?

Awesome explanation mate thank u

what does it mean when you have a knocking noise sounding like a lifter and then the knocking stops and then you have a misfire on cylinder 5

I have a clio rs200 mk3 2010

My engine blew up and I bought a new engine from a reconditioned engine company. The garage fitted the new engine and this engine didn’t come with a timing belt, they didn’t check this and tried starting the car without the belt. After finding out that the problem was the timing belt the car now start up but has a horrible sound. Like a sowing machine tapping. Can anybody help me to the reason why and what I need to do

[…] We’d encourage you to check out our original post on engine noises, but you were smart to check the connecting rod. Both the rod and the crank journal it rides on […]

I have a MGA 1600 with an in line four, 1588 cc’s, dual carbs I have a distinct knock at idle that disappears around 1200 revs.

It is my opinion that it is a valve train noise. I was bored 10 over and had the crank turned, plus new guides about 50K miles ago, about 45 years ago. Compression is 135 to 150, oil pressure steady at 60 with 10W40.

There are inspection ports under the manifold that give access to the tappets. It is my understanding that wear on the tappets (about 140,000 miles on the valve train) can be seen as pitting on the surface that meets the cam, or wear in the same spot. It is my understanding that this is more likely than wear to the sides of the tappet, which could cause the tappet equivalent of ‘piston slap’. I have been told that the tappets should be replaced as a set, and that it is advisable to replace the cam shaft at the same time. All parts are available new.

I would be grateful for opinions, here.

Thank you in advance.

I have a 1998 Chevy Astro minivan and recently had the power steering pump replaced, now it sounds like there is a rock rolling around in the motor.. what did he do wrong?

What does it mean when there is a misfire on cylinder 5 and a knocking noise that sounds like a lifter comes and goes?