As the guys at Chevy Hardcore point out, 500-horsepower ain’t what it used to be.

A 500 horsepower daily-driven street mill simply won’t garner attention at local meets or gas station pumps like it used to. To be honest, it’s almost too easy to make power these days with late-model mills such as the GM LS engine.

But is it cost-effective and practical?

Chevy Hardcore recently started a mission to build an LS engine that is all of the above: potent at the track, practical for the street, and reasonably cost-effective. They teamed up with the team at Late Model Engines (LME) in Houston, TX to assemble a 700-horsepower LS motor that could grind the asphalt at test-and-tune night at the local track and still get you home time after time.

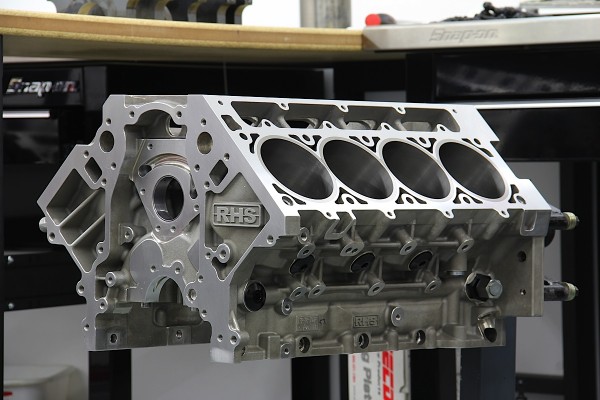

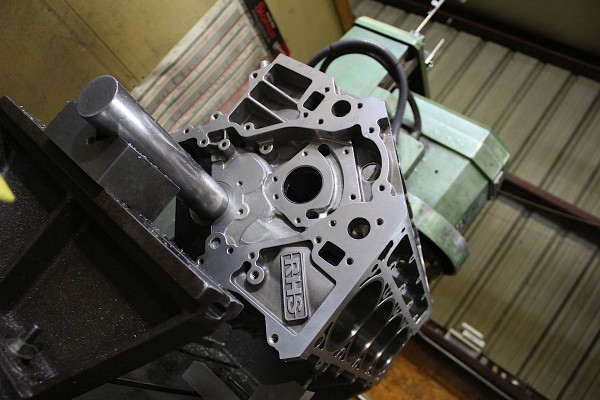

Can it be done? Yes—and the slideshow above will show you how. It covers the short block assembly of the Chevy Hardcore/LME LS build, which includes an RHS aluminum LSX engine block, Lunati crankshaft and connecting rods, Wiseco pistons, Total Seal piston rings, Clevite bearings, COMP Cams camshaft and lifters, and ARP hardware.

We’ll keep you updated on the project as it progresses.

[…] part one of Hardcore LS, we told you how Chevy Hardcore and Late Model Engines (LME) were putting together a stout, […]