It started off innocently enough. Following a race in 2010, Summit Racing Equipment NHRA Pro Stock driver Jason Line bought a 1968 Biscayne station wagon as a side project and laid out a quick, simple plan: take an old 427 motor from a donor car, refresh it, and drop it harmlessly between the frame rails of the wagon.

Then came Plan B.

“Almost from the start, the guys at the shop were hacking on me about putting a relatively stock engine into the wagon,” said Jason, who also builds and tunes the engines for the Summit Racing-sponsored KB Racing Pro Stock team. “That started me thinking. One thing led to another, and before I knew it, I was starting to assemble the pieces for a completely new custom motor.”

Jason’s “Plan B” was to build an all-new 557 cubic inch mill with the goal of topping 750 horsepower on pump gas. “A lot of people build 540s, 565s, or 572s, but I wanted something a little different,” Line said. “Basically, I wanted a race engine with low compression so I could drive it on the street.”

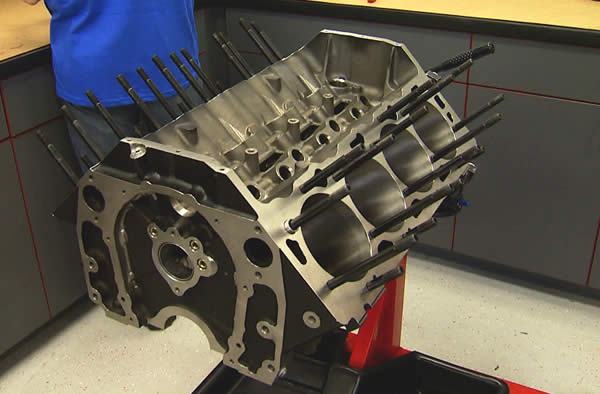

Jason started with a GM Performance Parts Gen VI 502 block with four-bolt mains to handle the considerable power he had planned. He had it bored out to 4.500 inches and clearanced for a 4.375-inch stroke crankshaft, producing 557 cubic inches. He then contacted Summit Racing to help piece together the components for the build.

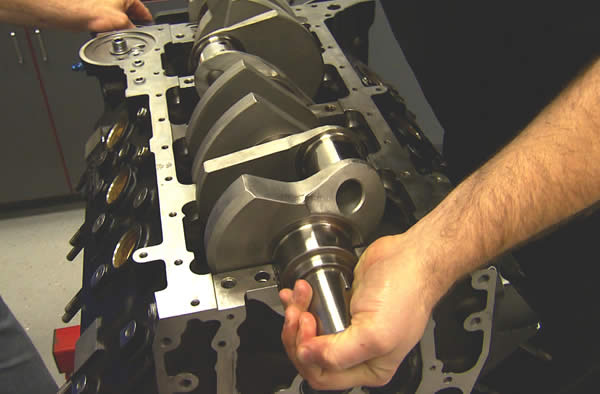

The rotating assembly includes an Eagle Specialties forged crank, Eagle Specialties H-beam connecting rods, and Diamond coated pistons. The top-end is anchored by a set of Trick Flow PowerPort® 360 cylinder heads, which got some special attention from Jason. Using his NASCAR and NHRA engine building experience, he altered the intake runners to increase airflow from 365 cfm to over 400 cfm. A port-matched Trick Flow single plane intake and a Willy’s carburetor complete the top end.

The valvetrain centers around a COMP Cams solid roller camshaft, which Jason says is mild and durable enough for the street without sacrificing the power numbers he was shooting for. In fact, the 557 exceeded Jason’s goals, delivering 812 horsepower on the dyno.

“Anyone can duplicate this build using parts right out of the Summit Racing catalog, bolt it all together without the extra port work, and get close to the horsepower we made,” Jason said. “That would certainly be enough for most people, but our team motto is: anything that can be done can be overdone.”

Jason Line’s 557 is proof of that.

Awsome ;o)

Awesome work I have a 502 gen 6 engine I would like to do the same to what size Carb And Cam did you use

Hi, I was wondering if Jason would be willing to donate the old motor from the Biscayne wagon?